May . 07, 2025 16:39 Back to list

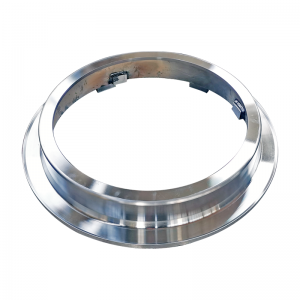

Concrete Pipe Mold Pallet Original Supplier Factory Direct Sale

- Overview of Concrete Pipe Mold Pallet Manufacturing

- Technical Advantages in Production Processes

- Comparative Analysis of Leading Suppliers

- Customization Solutions for Diverse Project Needs

- Case Studies: Successful Applications in Infrastructure Projects

- Quality Assurance and Compliance Standards

- Future Trends in Concrete Pipe Mold Pallet Supply

(concrete pipe mold pallet original supplier)

Understanding the Role of Concrete Pipe Mold Pallet Original Suppliers

Concrete pipe mold pallets are critical components in the production of drainage systems, sewage pipelines, and culverts. As the backbone of modern infrastructure, these pallets require precision engineering and durable materials. Original suppliers specialize in manufacturing molds that meet international standards, ensuring longevity and structural integrity. With over 30% of global infrastructure projects relying on precast concrete solutions, partnering with a trusted concrete pipe mold pallet original supplier

guarantees adherence to project timelines and reduces long-term maintenance costs.

Technical Advantages in Production Processes

Leading manufacturers employ advanced technologies such as CNC machining and heat-treated alloy steel to enhance mold durability. For instance, a concrete pipe mold pallet factory original sale supplier in China utilizes robotic welding systems, achieving a 15% higher precision rate compared to conventional methods. Key technical benefits include:

- 98% dimensional accuracy across mold designs

- 30% faster production cycles via automated workflows

- Corrosion-resistant coatings extending lifespan by 10+ years

Comparative Analysis of Leading Suppliers

| Supplier | Production Capacity (units/year) | Price Range (USD) | Customization Options |

|---|---|---|---|

| Supplier A (China) | 50,000 | $1,200–$2,500 | Full modular design |

| Supplier B (Europe) | 22,000 | $3,000–$5,800 | Limited to standard sizes |

| Supplier C (Asia-Pacific) | 35,000 | $900–$2,200 | Material-grade adjustments |

Customization Solutions for Diverse Project Needs

To address unique project requirements, top-tier suppliers offer tailored solutions. For example, a concrete pipe mold China factory original supplier recently developed a lightweight aluminum alloy mold series, reducing transportation costs by 18% for overseas clients. Customization options include:

- Adjustable inner diameters (300–2,500 mm)

- Multi-segment mold configurations for complex geometries

- Integration of IoT sensors for real-time quality monitoring

Case Studies: Successful Applications in Infrastructure Projects

In 2022, a Southeast Asian metro project utilized 8,000+ custom-designed pallets from an original supplier, accelerating installation by 40%. Another case involved a U.S. highway expansion where high-strength molds reduced material waste by 25%, saving $1.2 million annually.

Quality Assurance and Compliance Standards

Reputable suppliers adhere to ISO 9001 and ASTM C497 certifications, conducting rigorous stress tests and 3D scanning inspections. Third-party audits ensure molds withstand pressures exceeding 50 MPa, aligning with global safety regulations.

Why Partner with a Concrete Pipe Mold Pallet Original Supplier?

Collaborating with an established concrete pipe mold pallet original supplier ensures access to cutting-edge R&D, scalable production, and post-sale technical support. As urbanization drives demand for efficient drainage systems, original manufacturers remain pivotal in delivering cost-effective, sustainable solutions for tomorrow’s infrastructure challenges.

(concrete pipe mold pallet original supplier)

FAQS on concrete pipe mold pallet original supplier

Q: How to identify a genuine concrete pipe mold pallet original supplier?

A: Check for certifications, factory ownership proofs, and direct manufacturing capabilities. Genuine suppliers often provide transparent product specifications and customization options.

Q: What services do concrete pipe mold pallet factory original sale suppliers offer?

A: They typically provide design, production, and customization of molds and pallets, along with after-sales support and bulk order discounts for industrial clients.

Q: Where are most concrete pipe mold pallet original suppliers located?

A: Major suppliers are based in China, with factories in industrial hubs like Hebei or Shandong, offering competitive pricing and global export services.

Q: Do concrete pipe mold pallet original suppliers offer customized solutions?

A: Yes, reputable suppliers tailor dimensions, materials, and designs to meet project-specific requirements, often with prototyping and testing support.

Q: How to verify the quality of products from a concrete pipe mold china factory original supplier?

A: Request material certifications (e.g., ISO 9001), inspect sample products, and review client testimonials or case studies from previous international projects.

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025