stu . 29, 2024 16:19 Back to list

Understanding the Functionality of Shell and Tube Condensers in Refrigeration Systems

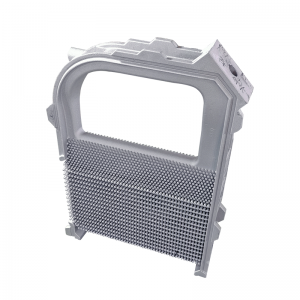

Refrigeration Shell and Tube Condenser A Comprehensive Overview

In the realm of refrigeration and air conditioning systems, condensers play a crucial role in converting refrigerant vapor into liquid. Among the various types of condensers available, the shell and tube condenser stands out for its efficiency, versatility, and robust design. This article delves into the operational principles, construction, applications, advantages, and maintenance of shell and tube condensers.

Operational Principles

A shell and tube condenser operates on a relatively simple yet effective principle. It consists of a series of tubes enclosed within a cylindrical shell. The refrigerant vapor enters the condenser and flows through the tubes, while a secondary cooling fluid—usually water—flows around the tubes in the shell. As the refrigerant vapor passes through the tubes, it releases heat to the cooling fluid, causing the vapor to condense into a liquid.

The design features a large surface area provided by the lengthy tubes, which enhances the heat transfer efficiency. This design allows for the effective cooling of the refrigerant while ensuring that the pressure remains stable, which is integral to the overall functionality of the refrigeration system.

Construction

The construction of shell and tube condensers typically involves several key components

1. Shell The outer casing that houses the tubes. It is usually made from corrosion-resistant materials to ensure durability.

2. Tubes These are the critical elements where the refrigerant undergoes phase change. They are designed with precise dimensions to facilitate optimal flow and heat transfer.

3. Tube Sheets These are end plates that hold the tubes in place and provide a barrier between the refrigerant and the cooling fluid.

4. Baffles These are internal structures that help direct the flow of the cooling water, ensuring that it flows evenly around the tubes and enhances heat transfer efficiency.

5. End Caps These components seal the ends of the shell and can be removable for maintenance and inspection.

Applications

Shell and tube condensers are widely used in various industries due to their adaptability and performance. Common applications include

- Refrigeration Systems Used in commercial and industrial refrigeration to condense refrigerants efficiently

.refrigeration shell and tube condenser

- HVAC Systems Implemented in heating, ventilation, and air conditioning systems to maintain optimal system performance.

- Power Plants Utilized in cooling systems for power generation processes.

- Chemical Processing Essential in processes that require precise temperature control and effective heat exchange.

Advantages

The popularity of shell and tube condensers can be attributed to several advantages

1. High Efficiency Their large surface area and effective heat transfer characteristics lead to high efficiency in heat exchange processes.

2. Versatility They can handle high pressures and temperatures, making them suitable for a variety of applications.

3. Easy Maintenance The design allows for easy cleaning and maintenance, as individual tubes can often be inspected and replaced without needing to remove the entire unit.

4. Scalability Shell and tube condensers can be easily scaled up to meet the demands of larger systems, making them a flexible choice for expanding operations.

Maintenance

Regular maintenance of shell and tube condensers is vital to ensure long-term efficiency and functionality. Common maintenance practices include

- Cleaning Regularly inspecting and cleaning the tubes to prevent fouling and scaling.

- Leak Checks Routinely checking for leaks in the system to prevent refrigerant loss and maintain system integrity.

- Monitoring Performance Keeping track of temperature and pressure readings to detect any deviations from normal operating conditions.

In conclusion, the shell and tube condenser is a highly efficient and versatile component of modern refrigeration systems. Its robust design, ease of maintenance, and adaptability to various applications have made it a staple in the industry. By understanding its operation, construction, and maintenance, users can maximize the performance and lifespan of refrigeration systems, thereby enhancing overall energy efficiency and effectiveness in various industrial processes.

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025