stu . 29, 2024 18:08 Back to list

Suppliers of Sodium Silicate for Sand Casting Applications and Solutions

The Role of Sodium Silicate in Sand Casting An Overview of Suppliers

Sodium silicate, commonly known as water glass, is a versatile compound widely utilized in various industrial applications, including sand casting. In the foundry industry, sodium silicate is an essential binder used in the preparation of sand molds and cores. This article delves into the importance of sodium silicate in sand casting and highlights some key considerations when selecting suppliers.

Understanding Sodium Silicate in Sand Casting

Sand casting is a prevalent manufacturing process that involves creating metal parts from molten metal poured into a mold. The mold is made from a combination of sand and a binding agent to hold the sand particles together. Sodium silicate serves as a binder in this process due to its excellent adhesive properties and ability to withstand high temperatures.

When sodium silicate is mixed with sand, it forms a robust framework that can support the weight and heat of molten metal. The sand mixture can be cured through chemical reactions or by applying heat. This characteristic not only enhances the strength of the mold but also provides greater flexibility in creating intricate designs.

Advantages of Using Sodium Silicate

1. High Temperature Resistance Sodium silicate molds can endure the extreme temperatures experienced during metal casting without deforming or breaking down.

2. Cost-Effectiveness Sodium silicate is a relatively inexpensive binder compared to other materials. It helps reduce production costs while maintaining quality.

3. Environmental Compliance With increasing regulations on environmental sustainability, sodium silicate is a more eco-friendly alternative to other organic binders that may emit volatile organic compounds (VOCs).

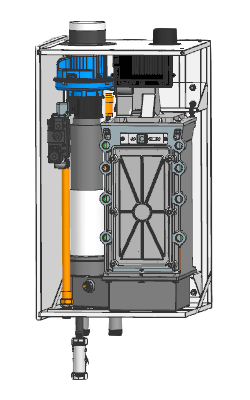

sodium slicate sand casting suppliers

Selecting Sodium Silicate Sand Casting Suppliers

When considering suppliers for sodium silicate used in sand casting, it's essential to evaluate several key factors

1. Quality and Purity The quality of sodium silicate can significantly impact the performance of sand molds. Suppliers should provide high-purity sodium silicate to ensure consistent results.

2. Technical Support A reputable supplier should offer technical guidance regarding the proper mixture ratios and curing processes for sodium silicate. This support helps manufacturers optimize their casting operations.

3. Customization Options Different casting applications may require specific formulations of sodium silicate. Suppliers that can customize their products to meet unique customer needs will have a competitive edge.

4. Delivery and Logistics Timely delivery is critical in the foundry industry. Suppliers should have efficient logistics in place to ensure that materials are delivered promptly and reliably.

5. Reputation and Experience Established suppliers with a proven track record in the industry are often more reliable. They are likely to have the experience needed to navigate the nuances of material sourcing and customer service.

Conclusion

Sodium silicate plays a crucial role in sand casting, providing essential properties needed for high-quality mold production. As demand grows within the foundry sector for efficient and reliable materials, the selection of suppliers for sodium silicate becomes increasingly important. By focusing on quality, technical support, customization options, and a solid reputation, manufacturers can establish successful partnerships with suppliers that enhance their casting processes and drive productivity.

Whether you are a large foundry or a small workshop, the right sodium silicate supplier can make a significant difference in the quality of your work. As the foundry industry continues to evolve, staying informed about suppliers and their offerings will help maintain a competitive edge, ensuring high-quality outputs that meet customer demands.

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025