Nov . 22, 2024 21:06 Back to list

stamping concrete pipe mould pallet manufacturers

The Role of Concrete Pipe Mould Pallets in the Manufacturing Industry

In the modern construction and infrastructure sector, the role of concrete pipe moulds and pallets cannot be overstated. As urbanization continues to rise and the demand for effective drainage and sewage systems increases, the necessity for high-quality concrete pipes has soared. With this increase in demand, manufacturers are constantly seeking efficient ways to produce these concrete pipes while maintaining quality. Among the key elements in this production process are the stamping concrete pipe moulds and the pallets they are placed on.

Understanding Concrete Pipe Moulds

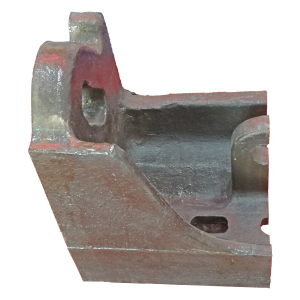

Concrete pipe moulds are specialized forms utilized to create cylindrical structures from concrete. The design and material of these moulds are critical as they determine the quality, durability, and functionality of the pipes produced. Moulds can be made from a variety of materials, including steel, plastic, or rubber, depending on the specific requirements of the production process. Each material offers unique benefits; for instance, steel provides strength and longevity, while plastic can offer flexibility and ease of use.

The stamping process in the production of concrete pipe moulds ensures that each mould is produced to exact specifications. This method allows manufacturers to create moulds that can withstand the rigors of continuous use while also ensuring that the dimensions of the pipes remain consistent. Precision in the moulding process directly impacts the integrity of the finished product, making high-quality moulds essential for effective manufacturing.

The Importance of Pallets

Pallets serve as the base on which concrete pipe moulds are set during the production process. They play a critical role in the logistics of concrete manufacturing, facilitating easy handling, transporting, and storage of moulds and finished products. High-quality pallets are designed to provide stability and support, ensuring that the moulds do not deform under the weight of the concrete mixture.

stamping concrete pipe mould pallet manufacturers

Additionally, the surface of the pallet can affect the finished quality of the concrete pipes. A smooth, well-maintained pallet can reduce the likelihood of surface imperfections on the pipes, leading to a higher quality product. Furthermore, pallets made from materials that resist moisture and wear contribute to the longevity of the moulds and the efficiency of the production process.

Manufacturers of Concrete Pipe Moulds and Pallets

The industry is rich with manufacturers specializing in the design and production of concrete pipe moulds and pallets. These manufacturers employ advanced technologies and techniques in producing their molds, ensuring that they meet the rigorous standards required in construction applications. When selecting a manufacturer, it is important to evaluate their experience, the materials they use, and the technology they employ in their production processes.

Quality assurance is another vital aspect to consider. Reputable manufacturers implement strict quality control measures to ensure that their products can withstand the demands of concrete production and environmental conditions. This attention to detail not only affects the immediate utility of the moulds and pallets but also their overall durability and lifespan.

Conclusion

The production of concrete pipes is an essential component of modern infrastructure, and the role of stamping concrete pipe moulds and pallets in this process is vital. By investing in high-quality moulds and pallets from reputable manufacturers, companies can ensure that they produce reliable, durable concrete pipes that meet the needs of their projects. As infrastructure development continues to evolve, the demand for efficient and effective manufacturing techniques will only increase, making the selection of the right moulds and pallets more important than ever. In a competitive market, staying ahead means prioritizing quality, reliability, and performance in every aspect of production.

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025