febr . 13, 2025 16:06 Back to list

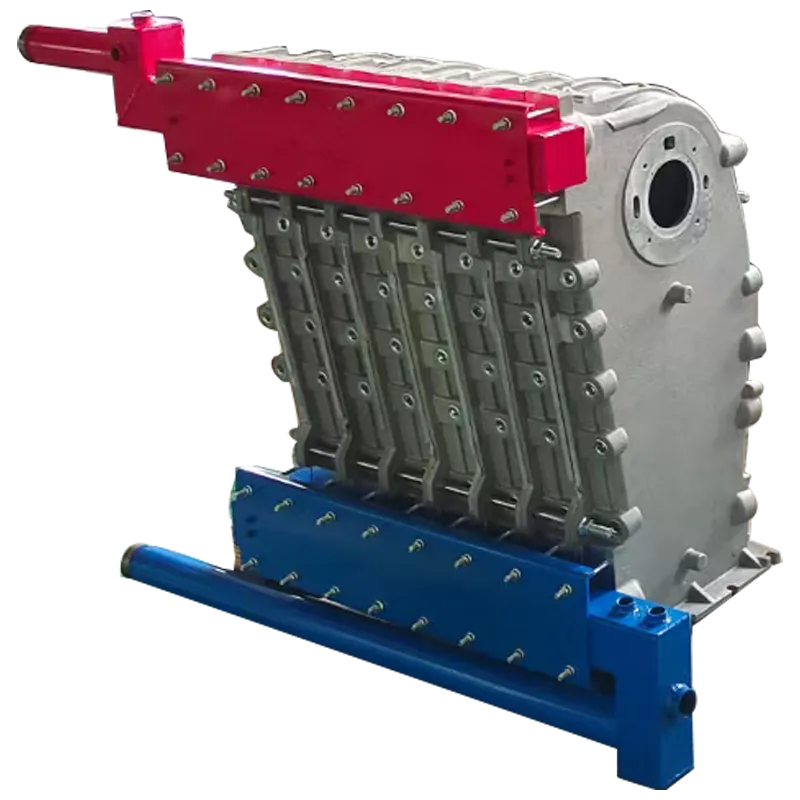

tube and plate heat exchanger

Industrial processes across the globe rely heavily on effective heat transfer systems to maintain efficiency, reduce costs, and ensure optimal performance. Among these systems, the tube and plate heat exchanger stands out as a versatile, reliable, and efficient solution suitable for a wide range of applications.

4. Maintenance and Durability Designed for easy access, these exchangers allow for straightforward maintenance and cleaning, ensuring longevity and consistent performance. High-quality materials enhance durability, minimizing the risk of leaks or structural failures. 5. Cost Efficiency Over time, the energy savings derived from their high efficiency, coupled with minimal maintenance needs, make tube and plate heat exchangers a cost-effective solution. Innovative Applications and Industry Use Cases The adaptability of tube and plate heat exchangers lends itself to numerous innovative applications. In the food and beverage industry, they are crucial for processes like pasteurization and sterilization, where maintaining precise temperatures is imperative. In the HVAC sector, they contribute to effective climate control by managing heat loads and improving energy efficiency. Furthermore, in the chemical and pharmaceutical industries, they assist in maintaining product integrity during sensitive production stages. Case Study Energy Optimization in Power Generation A leading power generation company recently integrated plate heat exchangers into their system, aiming to optimize their cogeneration process. The results were impressive—there was a 15% boost in thermal efficiency and a corresponding decrease in cooling water usage. This not only led to considerable cost savings but also reduced their environmental footprint, enhancing sustainability credentials. Conclusion Commitment to Quality and Expertise Choosing the right tube and plate heat exchanger provider is critical to maximizing the system's benefits. Look for manufacturers with proven expertise, quality materials, and a track record of reliability. Trustworthy suppliers will offer customizable solutions tailored to specific industry needs, backed by thorough testing and compliance with international standards. As industries increasingly prioritize energy efficiency and cost-effectiveness, the demand for advanced heat transfer solutions like tube and plate heat exchangers is set to rise. Investing in these systems ensures not just efficiency and savings but also positions companies as leaders in sustainable industrial practices.

4. Maintenance and Durability Designed for easy access, these exchangers allow for straightforward maintenance and cleaning, ensuring longevity and consistent performance. High-quality materials enhance durability, minimizing the risk of leaks or structural failures. 5. Cost Efficiency Over time, the energy savings derived from their high efficiency, coupled with minimal maintenance needs, make tube and plate heat exchangers a cost-effective solution. Innovative Applications and Industry Use Cases The adaptability of tube and plate heat exchangers lends itself to numerous innovative applications. In the food and beverage industry, they are crucial for processes like pasteurization and sterilization, where maintaining precise temperatures is imperative. In the HVAC sector, they contribute to effective climate control by managing heat loads and improving energy efficiency. Furthermore, in the chemical and pharmaceutical industries, they assist in maintaining product integrity during sensitive production stages. Case Study Energy Optimization in Power Generation A leading power generation company recently integrated plate heat exchangers into their system, aiming to optimize their cogeneration process. The results were impressive—there was a 15% boost in thermal efficiency and a corresponding decrease in cooling water usage. This not only led to considerable cost savings but also reduced their environmental footprint, enhancing sustainability credentials. Conclusion Commitment to Quality and Expertise Choosing the right tube and plate heat exchanger provider is critical to maximizing the system's benefits. Look for manufacturers with proven expertise, quality materials, and a track record of reliability. Trustworthy suppliers will offer customizable solutions tailored to specific industry needs, backed by thorough testing and compliance with international standards. As industries increasingly prioritize energy efficiency and cost-effectiveness, the demand for advanced heat transfer solutions like tube and plate heat exchangers is set to rise. Investing in these systems ensures not just efficiency and savings but also positions companies as leaders in sustainable industrial practices.

Share

Next:

Latest news

-

Centrifugally Cast Iron Water Main Pipe | Ductile Iron Solutions

NewsAug.24,2025

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025