Հկտ . 11, 2024 07:26 Back to list

aluminum die casting factory

The Advantages of Partnering with an Aluminum Die Casting Factory

In today's industrial landscape, the demand for lightweight, durable, and versatile materials has driven manufacturers to seek innovative solutions for their production needs. One such solution lies in the capabilities of aluminum die casting factories. This process not only enhances product performance but also contributes to cost-effectiveness and sustainability.

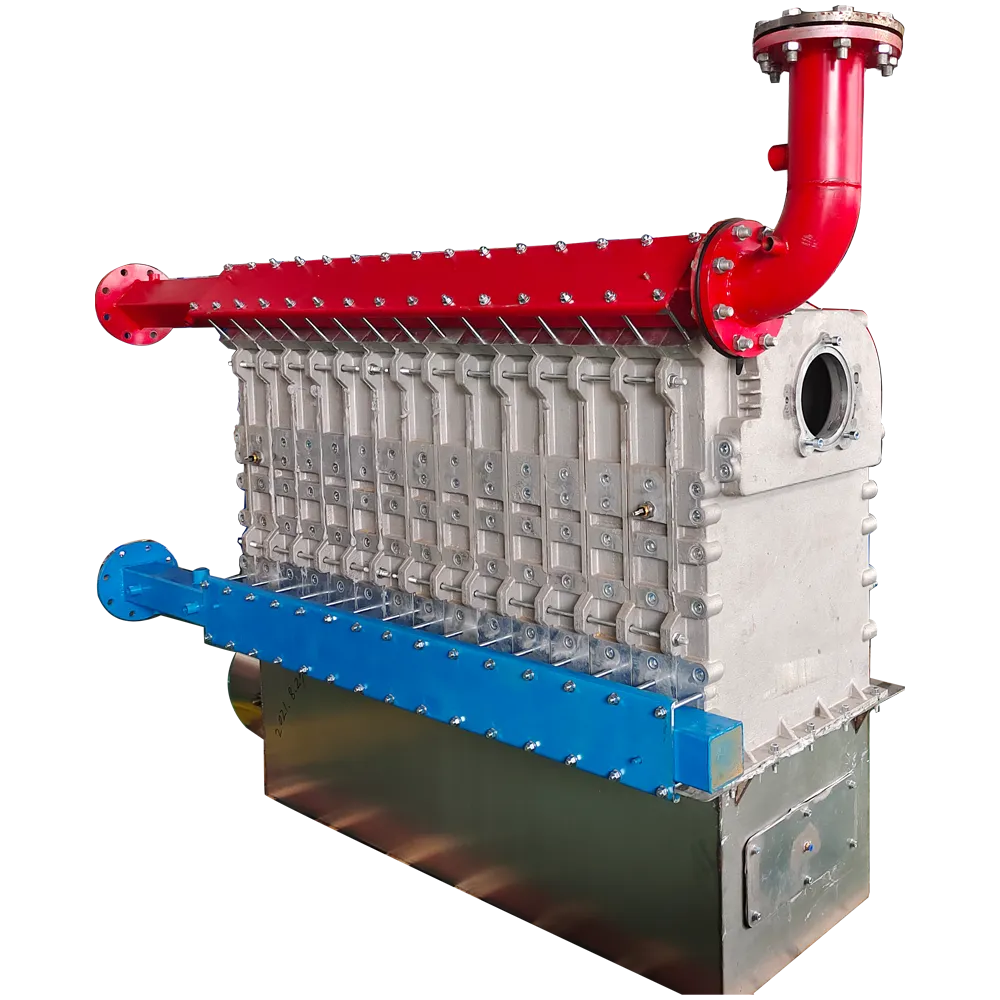

Aluminum die casting is a manufacturing process that involves forcing molten aluminum into a mold cavity under pressure. This technique allows for the creation of complex and intricate shapes with high precision and excellent surface finish. The strength-to-weight ratio of aluminum makes it an ideal choice for various applications across multiple industries, including automotive, aerospace, consumer electronics, and more.

One of the significant advantages of working with an aluminum die casting factory is the ability to achieve tight tolerances. Precision is crucial in many applications, especially in the automotive and aerospace sectors, where even minor inaccuracies can lead to substantial performance issues. Die casting provides the capability to produce parts with tolerances as tight as ±0.1 mm, making it a reliable option for manufacturers who prioritize quality.

aluminum die casting factory

Another benefit is the efficiency of the die casting process. Once the initial mold is created, the production cycle can be quite short, allowing for large quantities of parts to be produced rapidly. This speed of production not only reduces lead times but also lowers overall manufacturing costs, making it an attractive option for companies looking to streamline their supply chains.

Sustainability is also a critical consideration in today’s manufacturing environment. Aluminum is a recyclable material, and the die casting process generates minimal waste compared to other manufacturing methods. Partnering with a factory that emphasizes eco-friendly practices can enhance a company’s sustainability profile and appeal to environmentally conscious consumers.

Moreover, aluminum die casting factories often offer additional services such as machining, surface finishing, and assembly, allowing manufacturers to outsource multiple steps of production to a single partner. This integrated approach can lead to improved communication, consistency, and quality throughout the manufacturing process.

In summary, partnering with an aluminum die casting factory presents numerous advantages including precision, efficiency, sustainability, and the convenience of comprehensive services. As industries continue to evolve and the demand for high-performance lightweight components grows, aluminum die casting remains a pivotal solution for modern manufacturing challenges. By leveraging the expertise of specialized factories, companies can not only enhance their product offerings but also position themselves as leaders in innovation within their respective markets.

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025