Նյմ . 30, 2024 04:17 Back to list

nvestment casting factory

The Precision and Advantages of Investment Casting in Manufacturing

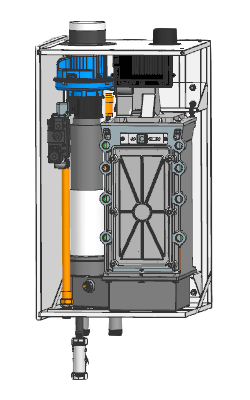

Investment casting, also known as lost-wax casting, is a sophisticated metal-forming process that has been utilized in various industries for centuries. The method is renowned for its ability to produce complex shapes with high accuracy and exceptional surface finish. As the demand for precision components rises in sectors such as aerospace, automotive, and medical devices, the role of investment casting factories becomes increasingly vital.

Understanding Investment Casting

The investment casting process begins with the creation of a wax model of the desired part. This model is coated with a ceramic shell, which is formed by applying multiple layers of fine sand and a bonding agent. Once the ceramic shell has hardened, the wax is melted and drained away, leaving a hollow mold. Molten metal is then poured into this mold to create the final product. After cooling, the ceramic shell is broken away to reveal the intricately detailed metal component.

This method has several advantages over traditional casting techniques. One of the most significant benefits is the exceptional level of detail and dimensional accuracy it provides. Investment casting can achieve tolerances as tight as ±0.005 inches and allows for complex geometries that would be difficult or impossible to create using other methods. This precision is crucial for applications where component failure is not an option, such as in aircraft engines or medical implants.

Versatility of Materials

Investment casting factories are capable of working with a wide range of metals, including aluminum, stainless steel, and bronze, among others. This versatility makes the process suitable for producing components for various industries. For example, in the aerospace sector, investment casting is often used to create turbine blades and other critical engine components. In the automotive industry, it can produce intricate parts like brackets and housing for transmissions.

Additionally, the nature of investment casting allows for the incorporation of different alloys, enabling manufacturers to tailor the mechanical properties of the final product to meet specific needs. Whether it be for strength, corrosion resistance, or weight, investment casting can accommodate a wide array of requirements.

nvestment casting factory

Economic Efficiency

While the initial setup for investment casting may be higher than other methods, the long-term economic benefits make it an attractive option for many manufacturers. The process is highly efficient due to reduced material waste, as the amount of metal needed is minimal compared to other methods. Moreover, the fine surface finish often leads to lower machining costs, as many components can be used without additional finishing.

Investment casting allows for the production of multiple items at once, which increases throughput and overall production efficiency. This scalability is beneficial for businesses looking to meet high-volume demands without sacrificing quality.

Sustainability Aspect

In today’s environmentally conscious market, investment casting factories are also focusing on sustainability. By optimizing material usage and minimizing waste, they contribute to more sustainable manufacturing practices. Furthermore, advancements in recycling processes allow for the reuse of metal scraps, thereby reducing the environmental impact of production.

Conclusion

Investment casting remains a crucial element in modern manufacturing due to its unparalleled precision, material versatility, and economic efficiency. As industries continue to evolve and demand components that can withstand the rigors of specific applications, investment casting factories will play an essential role in meeting these challenges. With a focus on quality and sustainability, investment casting is poised to remain a staple in the manufacturing landscape for years to come. As technology advances and new materials are developed, the possibilities for investment casting are practically limitless, confirming its status as a leading process in the realm of metal casting.

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025

-

Buy Cast Iron Pipe: Premium Ductile Iron & Drain Solutions

NewsAug.07,2025

-

Durable Cast Iron Water Main Pipe | Buy Ductile Pipe

NewsAug.06,2025