jan . 02, 2025 13:13 Back to list

cast steel pipe mould bottom ring manufacturers

The Importance of Quality in Cast Steel Pipe Mould Bottom Ring Manufacturing

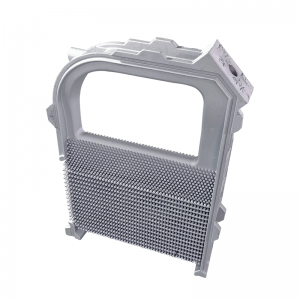

In the world of industrial manufacturing, cast steel components play a crucial role in various applications. One of these components, the cast steel pipe mould bottom ring, is essential in the casting and molding processes of pipes. The importance of quality in manufacturing these bottom rings cannot be overstated, as it directly affects the efficiency, durability, and performance of the final products.

Understanding Cast Steel Pipe Mould Bottom Rings

Cast steel pipe mould bottom rings are specialized components used to support the structure of molds during the casting process. They help maintain the shape and integrity of the mold, allowing for precise and uniform casting of pipes. These rings are typically made from high-quality cast steel, which provides the necessary strength and resistance to wear and tear. The production of these rings involves intricate processes, including casting, machining, and finishing, ensuring they meet the rigorous standards required for industrial applications.

The Manufacturing Process

The manufacturing of cast steel pipe mould bottom rings begins with the selection of high-grade raw materials. The steel is first melted in a furnace, where additives may be incorporated to enhance its properties. Once the steel reaches the desired temperature, it is poured into molds to create the bottom rings. After cooling, the rings undergo machining processes, such as turning, milling, and grinding, to achieve precise dimensions and surface finishes.

Quality control is a critical aspect throughout this entire manufacturing process. Reputable manufacturers implement strict quality assurance measures, including material testing, dimensional checks, and surface inspections. This ensures that every bottom ring produced meets the required specifications and industry standards.

The Role of Manufacturers

cast steel pipe mould bottom ring manufacturers

Choosing the right manufacturer for cast steel pipe mould bottom rings is vital. Experienced manufacturers often have a reputation for producing high-quality components that stand the test of time. They invest in advanced technologies and manufacturing techniques, allowing them to produce rings that not only meet but exceed customer expectations.

Additionally, top manufacturers offer customization options. Each project may have specific requirements concerning size, weight, and material properties. A skilled manufacturer can adjust their processes to create tailor-made solutions, providing clients with the exact specifications they need.

Benefits of High-Quality Bottom Rings

Investing in high-quality cast steel pipe mould bottom rings offers numerous benefits. Firstly, they enhance the overall durability of the molds, reducing the frequency of replacements and repairs. This not only saves costs but also minimizes downtime in production, leading to improved efficiency.

Secondly, quality bottom rings contribute to the accuracy of the casting process. They maintain the correct shape of the mold, ensuring that the pipes cast are uniform and meet the necessary standards. This precision is crucial in industries such as construction and plumbing, where the integrity and reliability of pipe systems are paramount.

Lastly, high-quality rings have better resilience against thermal and mechanical stresses. Pipes often undergo extreme conditions during manufacturing and in their end-use environments. Robust bottom rings can withstand these conditions, prolonging their lifespan and ensuring optimal performance.

Conclusion

Cast steel pipe mould bottom rings are integral components in the manufacturing of high-quality pipes. The role of manufacturers is critical in this process, as they ensure that these rings are produced to the highest standards. By investing in quality, manufacturers can significantly improve the efficiency, durability, and performance of their products. As industries continue to evolve, the demand for reliable cast steel components will only grow, making it essential for manufacturers to focus on quality and innovation in their processes. Choosing the right manufacturer can make all the difference in achieving optimal results in the competitive landscape of industrial manufacturing.

-

Centrifugally Cast Iron Water Main Pipe | Ductile Iron Solutions

NewsAug.24,2025

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025