Set . 14, 2024 08:03 Back to list

aluminum melt temperature

Understanding the Melting Temperature of Aluminum

Aluminum is one of the most widely used metals in various industries due to its lightweight, corrosion resistance, and excellent machinability. One of the fundamental properties of aluminum that is critical for both manufacturing and application is its melting temperature. The melting temperature, or melting point, of aluminum is approximately 660.3 degrees Celsius (1220.5 degrees Fahrenheit). Understanding this property is essential for processes such as casting, welding, and recycling.

Understanding the Melting Temperature of Aluminum

Aluminum's relatively low melting temperature is one of the reasons it is so widely employed in industries ranging from aerospace to automotive. It allows for easier processing and shaping of materials through methods such as die casting, extrusion, and forging. The ability to manipulate aluminum at lower temperatures means that energy consumption in processing can be significantly reduced compared to metals with higher melting points, such as steel.

aluminum melt temperature

Another aspect to consider is the effect of impurities on aluminum's melting temperature. While aluminum is generally considered a pure metal, it often contains trace amounts of other elements. These impurities can impact both the melting point and the mechanical properties of the final product. Consequently, achieving the desired aluminum purity plays a crucial role in applications where high performance is necessary, such as in aircraft or high-precision machinery.

When working with aluminum, understanding its melting point is vital for safety and quality control in manufacturing processes. For instance, during welding, if the temperature exceeds the melting point without proper control, it can lead to issues like excessive warping or even complete melting of the workpiece. Thus, operators must carefully monitor temperatures and adjust welding parameters to maintain the integrity of aluminum joints.

Recycling aluminum is another area where knowledge of the melting temperature is important. Aluminum is highly recyclable, and the recycling process typically involves melting the metal down. The efficiency of this process hinges on understanding and controlling temperatures, as higher temperatures can lead to energy waste and potential degradation of material properties. The melting point dictates not just the melting process but also influences the design of recycling furnaces and systems.

In conclusion, the melting temperature of aluminum is a critical parameter that affects its processing, application, and recycling. With a melting point of approximately 660.3 °C, aluminum offers unique advantages over many other metals due to its relatively low temperature threshold. As industries continue to innovate and demand higher performance from materials, understanding the intricacies of aluminum's melting temperature and its implications will remain essential for engineers and manufacturers alike.

-

Centrifugally Cast Iron Water Main Pipe | Ductile Iron Solutions

NewsAug.24,2025

-

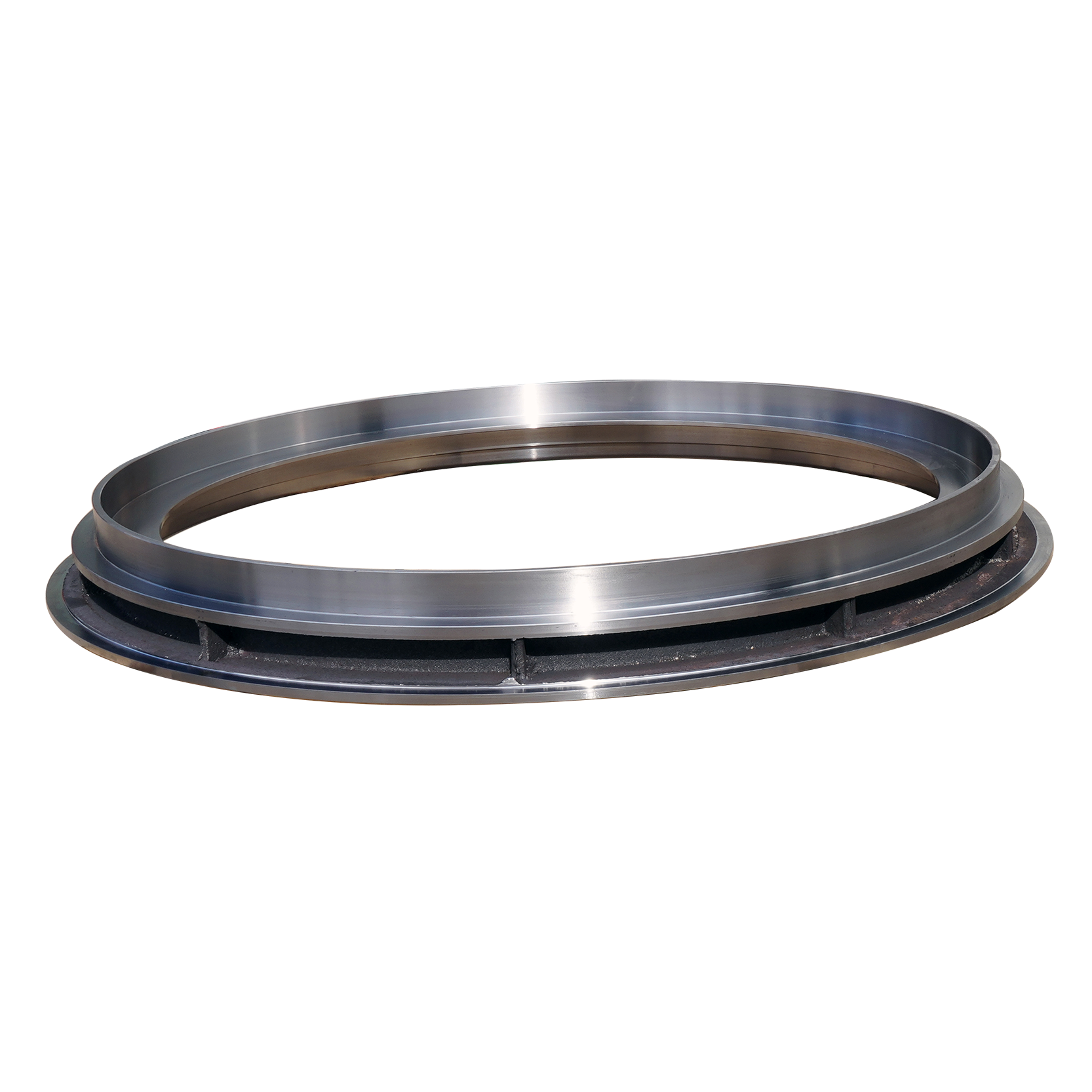

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025