Gen . 06, 2025 15:55 Back to list

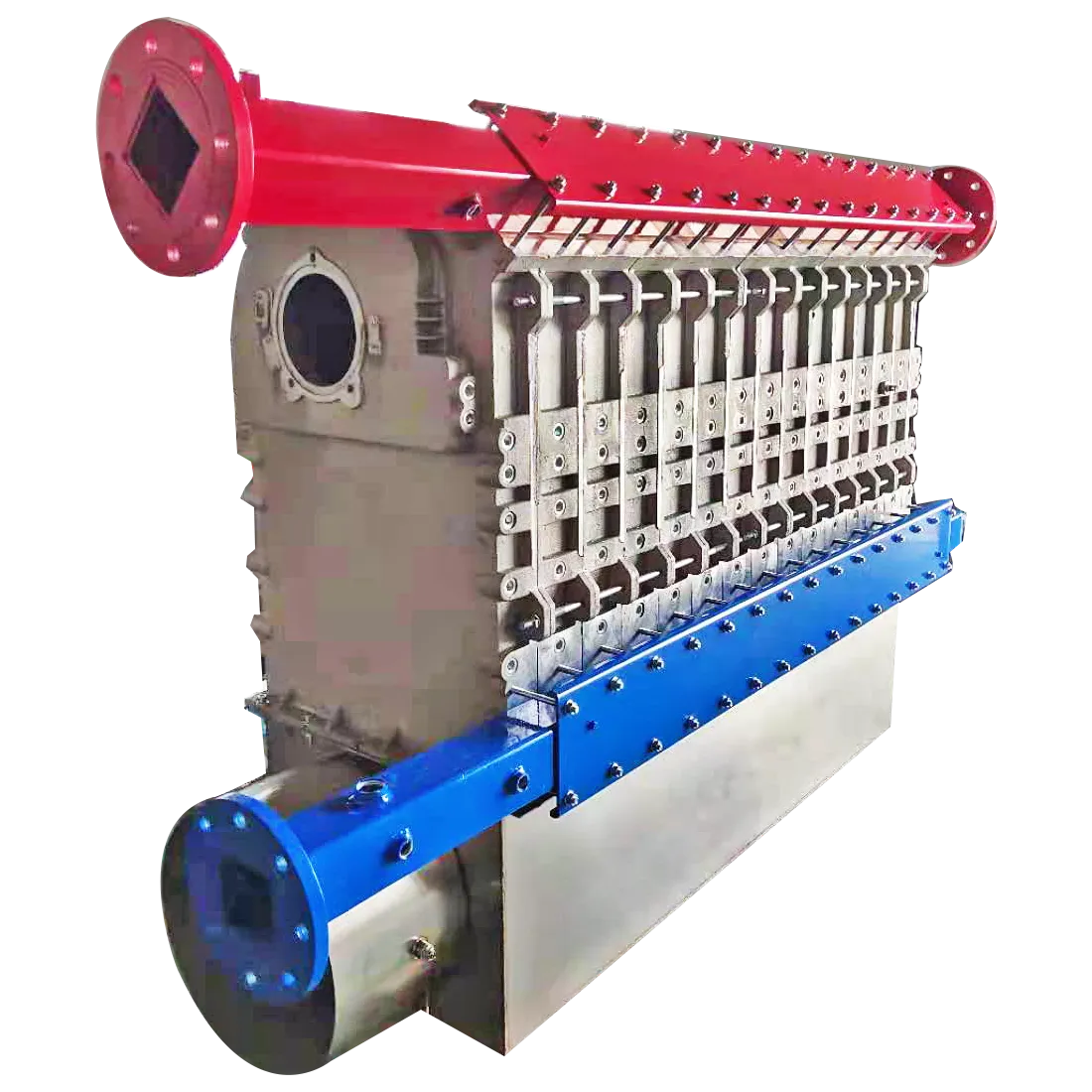

cement pipe mold/mould pallet

Cement pipe molds, often referred to as mould pallets, play a pivotal role in the production of concrete pipes, which are essential for infrastructure development worldwide. These molds are not just tools; they are the backbone of a process that demands precision, durability, and efficiency. Understanding the nuances of cement pipe molds is crucial for manufacturers striving to produce high-quality concrete pipes that meet international standards.

The production of concrete pipes using cement pipe molds involves a meticulous process where raw materials are transformed into robust, long-lasting products. The quality of the final product heavily depends on the design and material of the mold. Precision-engineered molds ensure uniformity in pipe thickness, a critical factor in maintaining structural integrity under various pressure conditions. Manufacturers must invest in molds crafted from high-grade steel or alloy, as these materials offer the strength and resilience necessary to withstand repeated use and the high-pressure environment of concrete compaction.

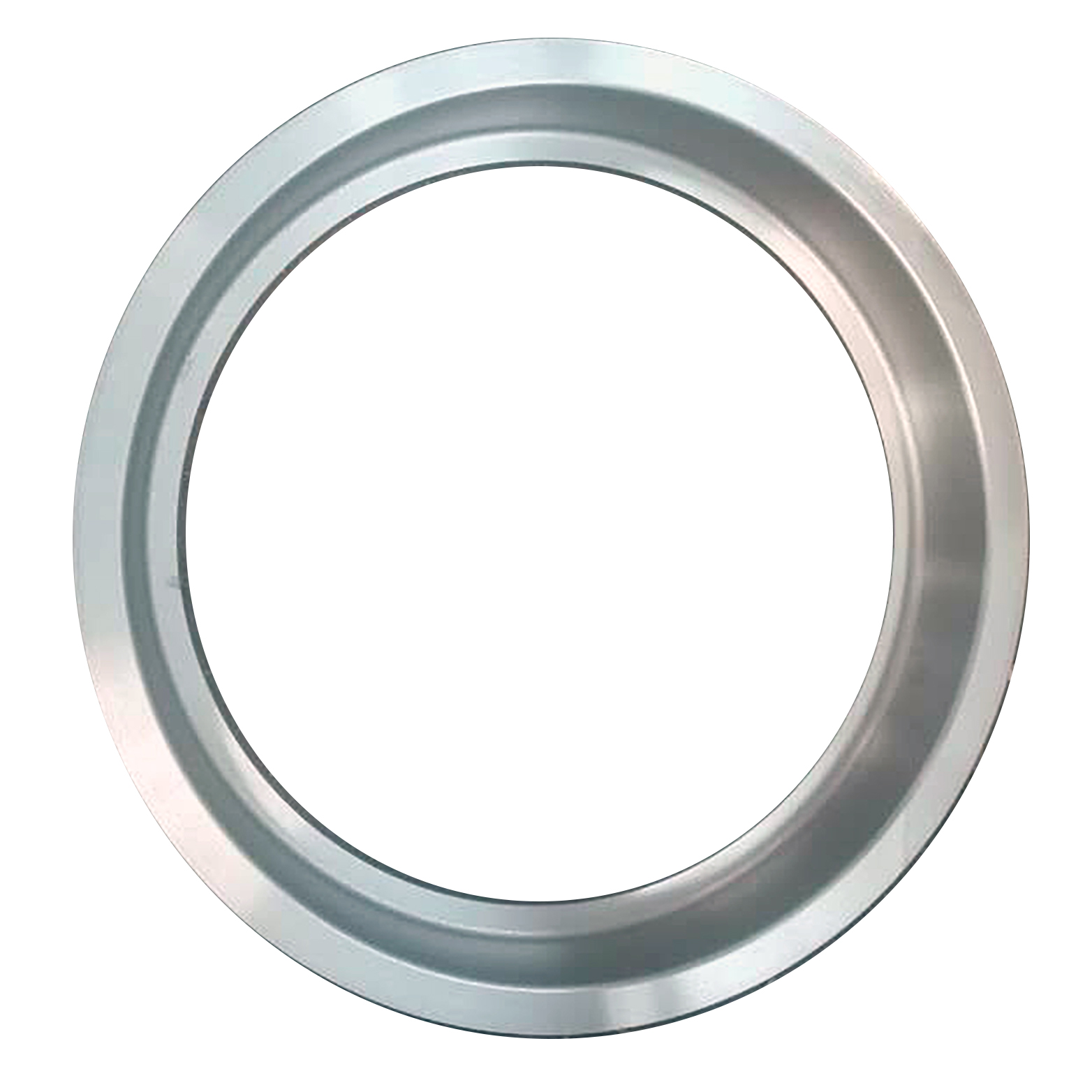

Expertise in the field demands a deep understanding of the manufacturing process, starting from the selection of the right mold to the nuances of the curing process. It's essential to collaborate with engineers who possess extensive experience in mold design. These professionals can provide insights into optimizing mold features such as joint tightness, end ring configurations, and surface finish, all of which contribute to the ease of demolding and enhance the quality of the final product.

Further emphasizing expertise and authoritativeness, manufacturers should seek partnerships with trusted mold suppliers who have a track record of innovation and excellence. Such suppliers typically offer customized solutions that cater to specific project requirements, ensuring that manufacturers can produce pipes of varying diameters and lengths while maintaining strict adherence to global standards.

cement pipe mold/mould pallet

In terms of trustworthiness, the reliability of cement pipe molds is non-negotiable. Manufacturers must ensure that every mold undergoes rigorous testing for durability and precision before use. This involves simulating conditions that the concrete pipes will face post-production, such as varying loads and environmental stresses. Implementing a robust quality assurance program underscores a company's commitment to delivering products that customers can rely on.

Experience, another critical factor, comes from years of involvement in the concrete pipe manufacturing industry. Seasoned manufacturers know that continuous learning and adaptation to new technologies are vital. This includes staying updated with advancements in mold design and concrete technology, which can lead to improvements in production efficiency and product performance.

The landscape of cement pipe manufacturing is constantly evolving, with new challenges and opportunities emerging. Manufacturers who prioritize the continuous enhancement of their molds and processes, guided by principles of experience, expertise, authoritativeness, and trust, will not only achieve operational excellence but also secure their position as leaders in the industry.

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025

-

Buy Cast Iron Pipe: Premium Ductile Iron & Drain Solutions

NewsAug.07,2025

-

Durable Cast Iron Water Main Pipe | Buy Ductile Pipe

NewsAug.06,2025