12月 . 11, 2024 12:32 Back to list

coal minning machinery casting suppliers

The Crucial Role of Casting Suppliers in Coal Mining Machinery

Coal mining has long been an essential industry, powering economies and providing energy resources worldwide. As the demand for coal continues, so does the need for efficient and innovative machinery to extract and transport this valuable resource. Central to the effectiveness of such machinery are the casting suppliers that provide the high-quality components necessary for reliable and durable equipment.

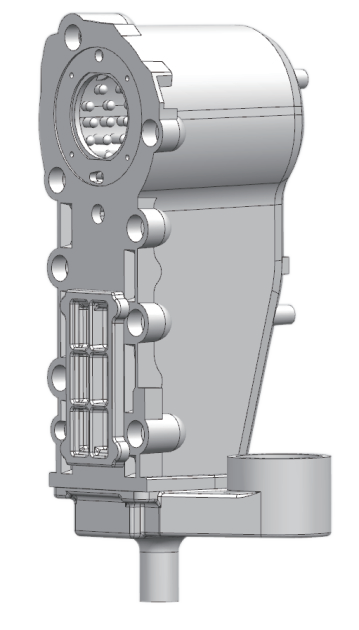

Casting is a manufacturing process where molten metal is poured into a mold and allowed to solidify into a desired shape. In the context of coal mining machinery, various components such as gears, frames, and support structures are produced through casting. The precision and quality of these cast components directly impact the performance and longevity of the machinery used in coal extraction.

The Importance of Quality in Casting

The coal mining industry often operates in high-stress environments, where machinery faces extreme wear and tear. As a result, sourcing components from reputable casting suppliers is crucial. High-quality materials and precise manufacturing processes ensure that parts can withstand the heavy loads and abrasive conditions typical of mining operations.

Key factors that determine the quality of cast components include the type of material used, the casting method employed, and the supplier's manufacturing capabilities. For instance, cast iron and various grades of steel are common materials used in mining machinery due to their strength and durability. Additionally, advanced casting techniques such as sand casting, investment casting, and die casting can produce components with intricate designs and superior structural integrity.

Innovations in Casting Technology

coal minning machinery casting suppliers

The casting industry is continuously evolving, with suppliers implementing new technologies to enhance the quality and efficiency of their products. Additive manufacturing, often referred to as 3D printing, is gaining traction within the casting sector, allowing for quicker prototyping and more complex designs that traditional methods may not accommodate. This innovation enables casting suppliers to meet the specific needs of coal mining companies, offering customized solutions that improve the performance of their machinery.

Furthermore, the integration of modern computer-aided design (CAD) and simulation software has revolutionized the way casting suppliers operate. This technology allows for detailed modeling of components before they are produced, reducing the risk of defects and ensuring that the final product meets the required specifications. Such advancements benefit coal mining operations by minimizing downtime caused by equipment failures and replacements.

Environmental Considerations

As the coal industry faces increasing scrutiny over its environmental impact, so too do casting suppliers need to adapt. There is a growing emphasis on sustainable practices within manufacturing processes, including the use of recycled materials and the reduction of waste during production. Suppliers who prioritize sustainability can help coal mining companies meet their environmental objectives while also delivering high-quality products.

Selecting the Right Casting Supplier

Choosing the right casting supplier is a critical decision for coal mining companies. Factors to consider include the supplier's experience in the mining sector, their production capabilities, and their commitment to quality and sustainability. Establishing a strong partnership with a reliable supplier can significantly influence a mining company’s operational efficiency and bottom line.

In conclusion, casting suppliers play an indispensable role in the coal mining industry, providing the essential components necessary for high-performing machinery. As technology continues to advance and environmental concerns gain prominence, these suppliers must evolve to meet the changing demands of the industry. By focusing on quality, innovation, and sustainability, casting suppliers can ensure that coal mining operations remain efficient and competitive in a rapidly changing world.

-

Premium Cast Iron Water Main Pipe for Robust Infrastructure

NewsAug.27,2025

-

A-Rated Cast Aluminum Boilers: High-Efficiency Condensing Gas & LPG

NewsAug.26,2025

-

OEM Cast Silicon Aluminum Alloy Heat Exchanger | Custom & High Performance

NewsAug.25,2025

-

Centrifugally Cast Iron Water Main Pipe | Ductile Iron Solutions

NewsAug.24,2025

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025