Feb . 10, 2025 10:08 Back to list

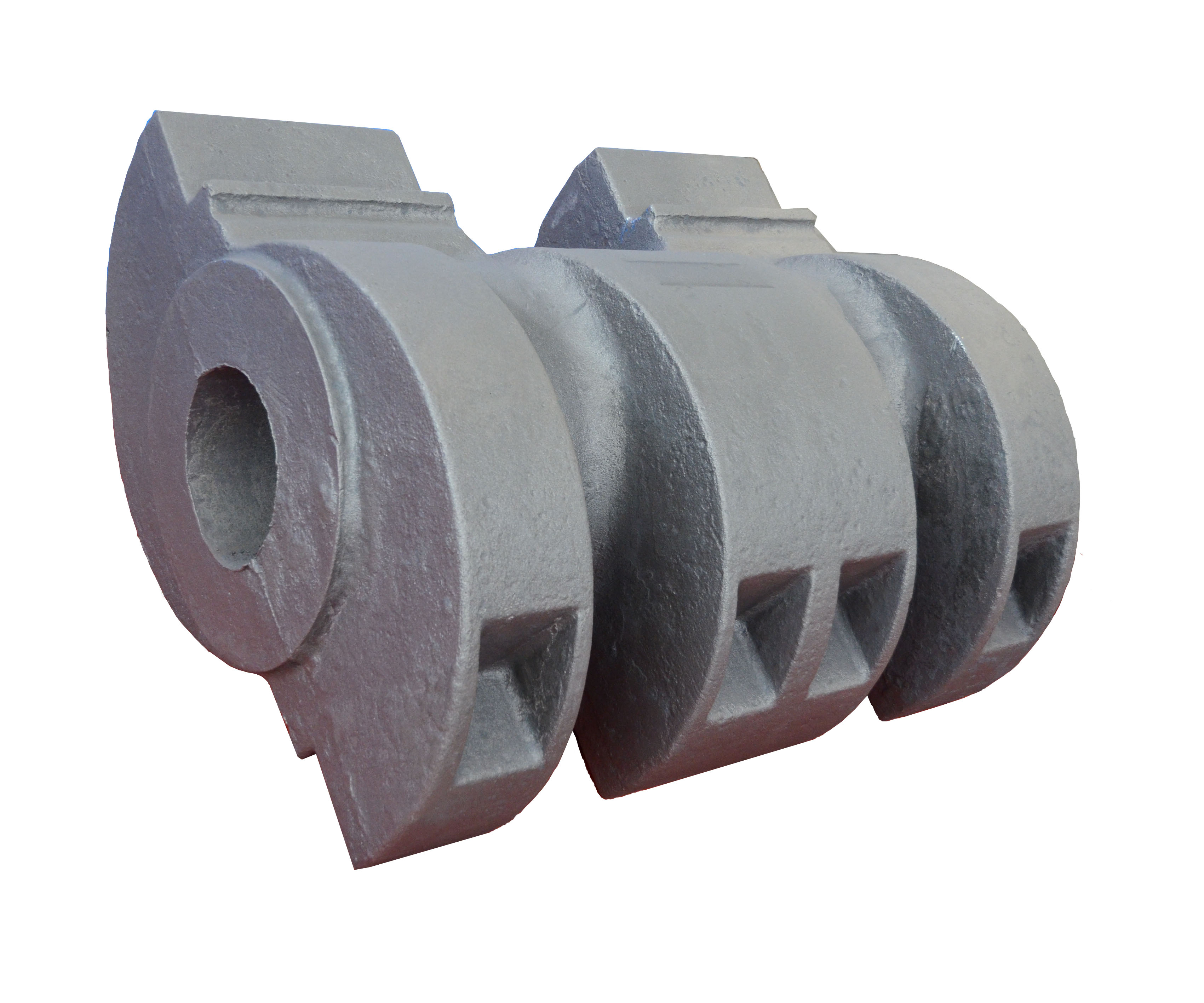

oem cast silicon aluminum alloy heat exchanger

The quest for energy efficiency in industrial applications has placed a significant amount of attention on cutting-edge solutions like gas heat exchangers. As industries grow more conscientious about reducing their carbon footprint, the need for advanced and reliable thermal management systems has never been greater. Gas heat exchangers have emerged as critical components in this drive, providing unmatched efficiency and adaptability.

The installation and maintenance of gas heat exchangers require expertise and meticulous attention to detail. Proper installation ensures optimal performance and prolongs the life expectancy of the equipment. Regular maintenance, including inspections and cleaning of exchanger surfaces, ensures that the system operates at peak efficiency and prevents costly downtime. Partnering with experienced professionals who can provide ongoing support and technical advice is crucial in maintaining the system’s integrity. Another dimension of gas heat exchangers' appeal is their environmental impact. By effectively managing heat and reducing waste, these systems promote sustainability. This aligns with global regulatory frameworks and industry standards aimed at minimizing carbon emissions and championing eco-friendly practices. Enterprises that invest in gas heat exchanger technology not only meet regulatory demands but also enhance their brand reputation by demonstrating a commitment to environmental responsibility. Looking ahead, innovations in gas heat exchanger technology continue to evolve, driven by both industrial demand and advances in material science. Emerging technologies such as nanotechnology and 3D printing promise even greater efficiencies and capabilities, allowing for more customized and efficient designs. As artificial intelligence and machine learning progress, predictive maintenance and real-time system optimization will become standard, further enhancing the reliability and efficiency of heat exchangers. In conclusion, gas heat exchangers stand as a testament to the blend of practical ingenuity and technological advancement. Their significance in industrial energy management is profound, offering diverse applications, economic benefits, and a direct path to environmental sustainability. As industries continue to embrace these advances, the role of gas heat exchangers will only become more pivotal in shaping a sustainable industrial future. Investing in quality gas heat exchangers is not just a matter of immediate efficiency gains but is a strategic decision for long-term operational and environmental benefits.

The installation and maintenance of gas heat exchangers require expertise and meticulous attention to detail. Proper installation ensures optimal performance and prolongs the life expectancy of the equipment. Regular maintenance, including inspections and cleaning of exchanger surfaces, ensures that the system operates at peak efficiency and prevents costly downtime. Partnering with experienced professionals who can provide ongoing support and technical advice is crucial in maintaining the system’s integrity. Another dimension of gas heat exchangers' appeal is their environmental impact. By effectively managing heat and reducing waste, these systems promote sustainability. This aligns with global regulatory frameworks and industry standards aimed at minimizing carbon emissions and championing eco-friendly practices. Enterprises that invest in gas heat exchanger technology not only meet regulatory demands but also enhance their brand reputation by demonstrating a commitment to environmental responsibility. Looking ahead, innovations in gas heat exchanger technology continue to evolve, driven by both industrial demand and advances in material science. Emerging technologies such as nanotechnology and 3D printing promise even greater efficiencies and capabilities, allowing for more customized and efficient designs. As artificial intelligence and machine learning progress, predictive maintenance and real-time system optimization will become standard, further enhancing the reliability and efficiency of heat exchangers. In conclusion, gas heat exchangers stand as a testament to the blend of practical ingenuity and technological advancement. Their significance in industrial energy management is profound, offering diverse applications, economic benefits, and a direct path to environmental sustainability. As industries continue to embrace these advances, the role of gas heat exchangers will only become more pivotal in shaping a sustainable industrial future. Investing in quality gas heat exchangers is not just a matter of immediate efficiency gains but is a strategic decision for long-term operational and environmental benefits.

Share

Latest news

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025