Dec . 02, 2024 01:19 Back to list

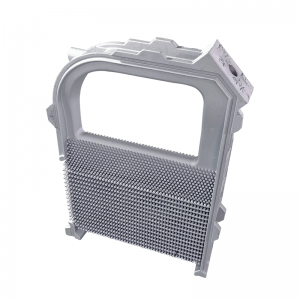

grey iron foundry

The Significance of Grey Iron Foundry in Modern Manufacturing

Grey iron, a type of cast iron known for its excellent castability and machinability, plays a pivotal role in the manufacturing sector, particularly in foundries dedicated to producing grey iron products. The grey iron foundry industry has evolved significantly over the decades, adapting to technological advancements, changing market demands, and environmental considerations. This article delves into the significance of grey iron foundries, their applications, and the future outlook.

Understanding Grey Iron

Grey iron is characterized by its graphite flakes that give it a grey appearance when fractured. Due to its unique microstructure, this material exhibits exceptional fluidity when molten, allowing it to fill complex molds easily. Additionally, grey iron has good wear resistance and damping capabilities, making it suitable for a wide range of applications, from automotive components to industrial machinery.

Applications of Grey Iron

The versatility of grey iron makes it indispensable in various industries

1. Automotive Industry Grey iron is widely used in the manufacturing of engine blocks, cylinder heads, and brake components. Its ability to withstand thermal stresses and its stability under high temperatures make it ideal for critical automotive parts.

2. Construction In construction, grey iron is utilized for producing castings like manhole covers, drain grates, and various structural components. These products benefit from the material’s durability and resistance to corrosion.

3. Machine Parts Many industrial machineries use grey iron for components such as gear housings, frames, and support structures. The ability to absorb vibrations enhances the performance and longevity of machinery.

4. Pipes and Fittings Grey iron is also employed in pipelines for transporting fluids, as it can withstand high pressures and has good sealing properties.

grey iron foundry

The Foundry Process

The production of grey iron involves several key processes. It begins with melting scrap iron or pig iron in a furnace. The molten iron is then treated with alloying elements to achieve desired properties. Once the mixture is homogenous, it is poured into molds to create specific shapes. The molds can be made from sand, metal, or other materials, and the choice of mold impacts the final quality of the castings. After cooling, the cast pieces are removed from the molds and subjected to various finishing processes, including machining and surface treatment.

Environmental Considerations

As with any manufacturing process, grey iron foundries face environmental challenges, including emissions and waste management. Many foundries are taking significant steps to reduce their environmental footprint. Innovations such as cleaner melting technologies and recycling of foundry sand have been implemented to enhance sustainability. Additionally, regulatory compliance has prompted foundries to adopt best practices in emissions control and waste reduction.

Future Outlook

The future of grey iron foundries appears promising, given the increasing demand for durable and efficient materials across various sectors. The automotive industry is transitioning towards electric vehicles, which may impact the demand for traditional cast iron components. However, grey iron is likely to remain relevant due to its properties that are essential for specific applications, particularly in electric vehicle manufacturing and infrastructure development.

Moreover, advancements in additive manufacturing and digital technologies such as 3D printing are expected to revolutionize the foundry landscape. These technologies could allow for more complex designs and lower material waste, enabling grey iron foundries to compete effectively in a rapidly changing market.

Conclusion

In summary, grey iron foundries are a cornerstone of modern manufacturing, supplying vital components across a multitude of industries. Their ability to adapt to technological and environmental challenges will dictate their success in the future. As industries evolve, grey iron remains a critical material, underscoring the ongoing importance of foundries in the global economy. The intersection of innovation and traditional practices within grey iron foundries will undoubtedly shape the future of manufacturing, making it an exciting field to watch in the years to come.

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025