Sep . 19, 2024 15:55 Back to list

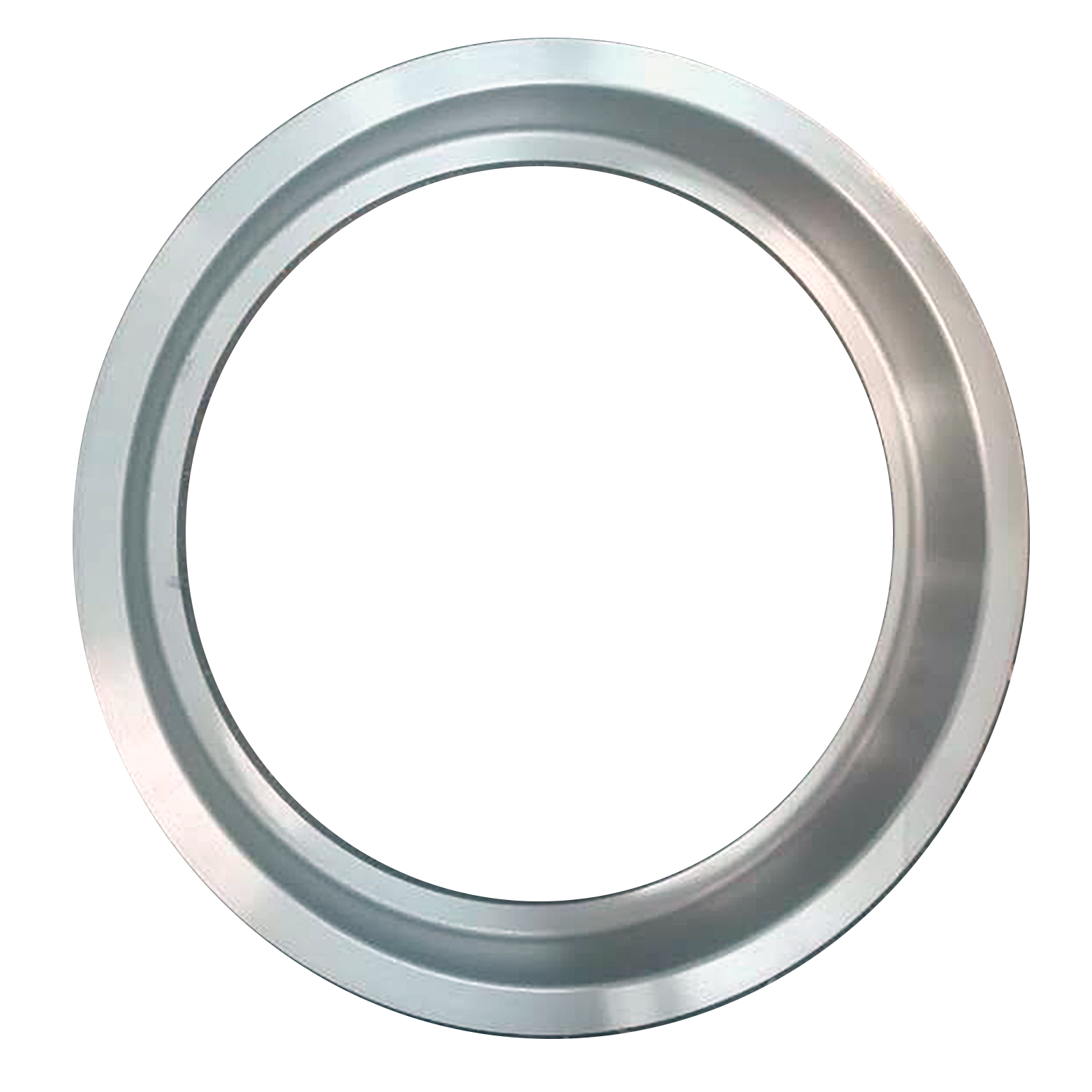

wholesale ductile iron pipe mold bottom ring

Understanding the Wholesale Ductile Iron Pipe Mold Bottom Ring

In the world of pipeline manufacturing and infrastructure development, the importance of durable and reliable materials cannot be overstated. One key component that plays a significant role in this sector is the ductile iron pipe mold bottom ring. This article aims to shed light on what ductile iron is, the advantages of using it for pipe manufacturing, and the crucial role that the bottom ring plays in ensuring the integrity and efficiency of pipelines.

Ductile iron, also known as nodular cast iron, was developed in the 1940s and has since become a preferred material for pipes and pipe fittings due to its excellent mechanical properties. This alloy exhibits a high tensile strength, durability, and resistance to corrosion, making it ideal for use in a variety of harsh environments. Furthermore, its ability to withstand impacts means that ductile iron can endure the stresses to which pipes are often subjected during transportation and installation.

The pipe manufacturing process is complex and requires precision at every step. The bottom ring of a ductile iron pipe mold is one of the integral components that ensures the correct shape and size of the pipe. It serves as the foundation for the mold, allowing for an accurate and secure casting process. When molten iron is poured into the mold, the bottom ring holds the liquid metal in place, ensuring that it solidifies into the desired form without any leaks or deformities. This precision is crucial, as even minor discrepancies can lead to significant issues in pipeline functionality and safety.

wholesale ductile iron pipe mold bottom ring

Wholesale procurement of ductile iron pipe mold bottom rings is essential for manufacturers looking to maintain cost-effectiveness while ensuring high-quality production. Bulk purchasing enables manufacturers to reduce costs significantly. This is particularly important in an industry where margins can be tight, and the demand for durability is non-negotiable.

Furthermore, bulk purchases often come with additional benefits, such as consistent material quality and assured availability. Reliable suppliers of wholesale ductile iron pipe mold bottom rings are typically vetted and offer products that meet industry standards, ensuring that manufacturers receive components that will perform optimally in their applications. When the bottom rings are created with precision and from high-quality ductile iron, it not only impacts the quality of the pipes produced but also minimizes the risks associated with pipe failure, which can lead to costly repairs and potential hazards.

The advantages of using ductile iron pipe mold bottom rings extend beyond just manufacturing efficiency. Pipes made using these components are often more resilient to environmental factors such as soil movement, temperature fluctuations, and even seismic events. This resilience contributes to a longer lifespan for pipelines and less frequent replacement, ultimately saving money and resources.

In conclusion, the wholesale ductile iron pipe mold bottom ring is a critical component in the pipeline industry. The combination of ductile iron’s remarkable properties and the strategic design of the bottom ring facilitates the production of high-quality, durable pipes. For manufacturers, investing in these wholesale components not only improves the overall efficiency of their operations but also enhances the safety and reliability of the infrastructure they help build. As the demand for effective and dependable pipeline solutions continues to rise, the significance of these components will undoubtedly grow.

-

OEM Cast Silicon Aluminum Alloy Heat Exchanger | Custom & High Performance

NewsAug.25,2025

-

Centrifugally Cast Iron Water Main Pipe | Ductile Iron Solutions

NewsAug.24,2025

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025