თებ . 12, 2025 16:10 Back to list

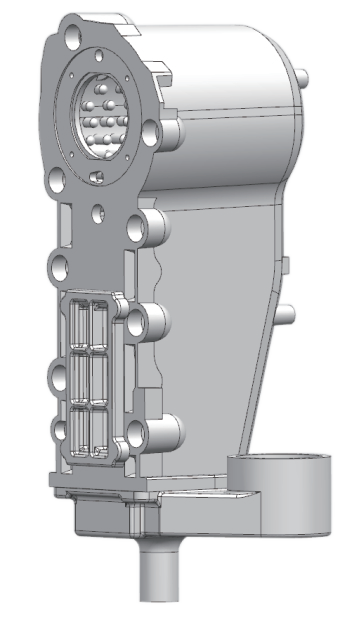

CONCRETE PIPE MOLD PALLETS

Selecting the right tubing for heat transfer applications is crucial for optimizing performance in industries ranging from HVAC to chemical processing. An exceptional choice can lead to increased efficiency, reduced costs, and enhanced durability. This article delves into the different types of tubing materials and designs, shedding light on their unique advantages and the scenarios they best serve.

Emerging materials and technologies have also introduced PEX (cross-linked polyethylene) tubing into the heat transfer landscape. Popular in residential and commercial plumbing, PEX offers flexibility, ease of installation, and resistance to scale and chlorine. While its thermal conductivity is lower than metals, PEX is valued in hydronic heating systems for its energy efficiency and cost-effectiveness. Consider its temperature limitations and compatibility with system components when integrating PEX tubing. Engineered tubing, such as finned or corrugated designs, has evolved to address specific heat transfer challenges. Finned tubes enhance surface area exposure, significantly improving heat exchange rates. This makes them indispensable in heat exchangers and boilers. Corrugated tubes, with their undulating shapes, create turbulent flow, enhancing heat transfer efficiency. These engineered solutions demonstrate how slight design enhancements can lead to substantial performance improvements. When selecting tubing for heat transfer, it’s imperative to consider the specific requirements of the application, including thermal conductivity, environmental conditions, material compatibility, and budget constraints. Consultation with industry experts and thorough testing can ensure the chosen tubing meets the system's performance expectations while adhering to safety and regulatory standards. Implementing the best tubing solution not only optimizes heat transfer efficiency but also extends the lifespan of the system, reducing maintenance needs and operational costs. Ultimately, the right choice strengthens competitive advantage and fosters energy conservation, aligning with modern-day sustainability goals. For business leaders and engineers aiming to achieve excellence, informed decisions on tubing materials and designs are integral to building robust, efficient systems.

Emerging materials and technologies have also introduced PEX (cross-linked polyethylene) tubing into the heat transfer landscape. Popular in residential and commercial plumbing, PEX offers flexibility, ease of installation, and resistance to scale and chlorine. While its thermal conductivity is lower than metals, PEX is valued in hydronic heating systems for its energy efficiency and cost-effectiveness. Consider its temperature limitations and compatibility with system components when integrating PEX tubing. Engineered tubing, such as finned or corrugated designs, has evolved to address specific heat transfer challenges. Finned tubes enhance surface area exposure, significantly improving heat exchange rates. This makes them indispensable in heat exchangers and boilers. Corrugated tubes, with their undulating shapes, create turbulent flow, enhancing heat transfer efficiency. These engineered solutions demonstrate how slight design enhancements can lead to substantial performance improvements. When selecting tubing for heat transfer, it’s imperative to consider the specific requirements of the application, including thermal conductivity, environmental conditions, material compatibility, and budget constraints. Consultation with industry experts and thorough testing can ensure the chosen tubing meets the system's performance expectations while adhering to safety and regulatory standards. Implementing the best tubing solution not only optimizes heat transfer efficiency but also extends the lifespan of the system, reducing maintenance needs and operational costs. Ultimately, the right choice strengthens competitive advantage and fosters energy conservation, aligning with modern-day sustainability goals. For business leaders and engineers aiming to achieve excellence, informed decisions on tubing materials and designs are integral to building robust, efficient systems.

Share

Pervious:

Latest news

-

Centrifugally Cast Iron Water Main Pipe | Ductile Iron Solutions

NewsAug.24,2025

-

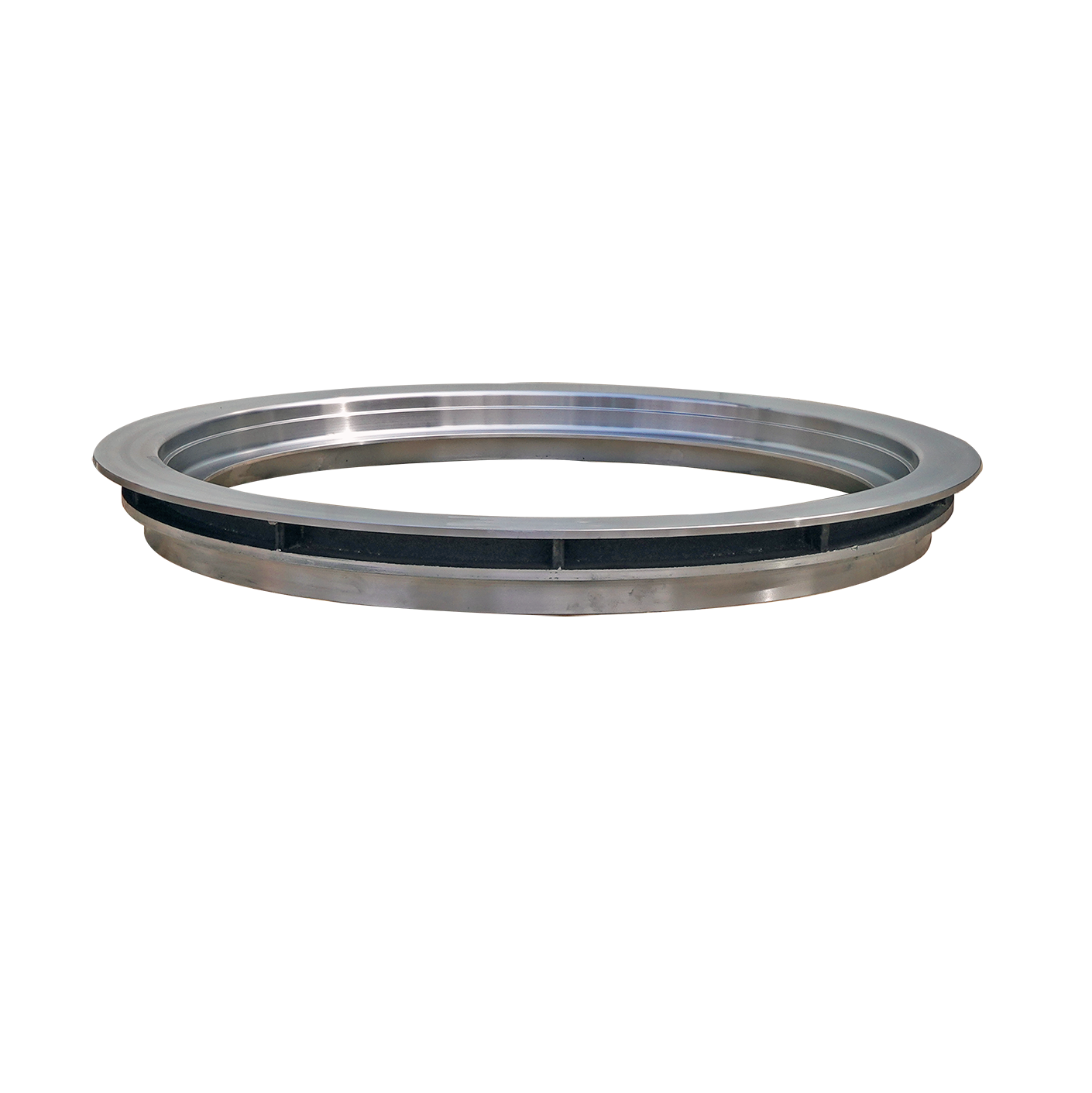

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025