ოქტ . 19, 2024 06:47 Back to list

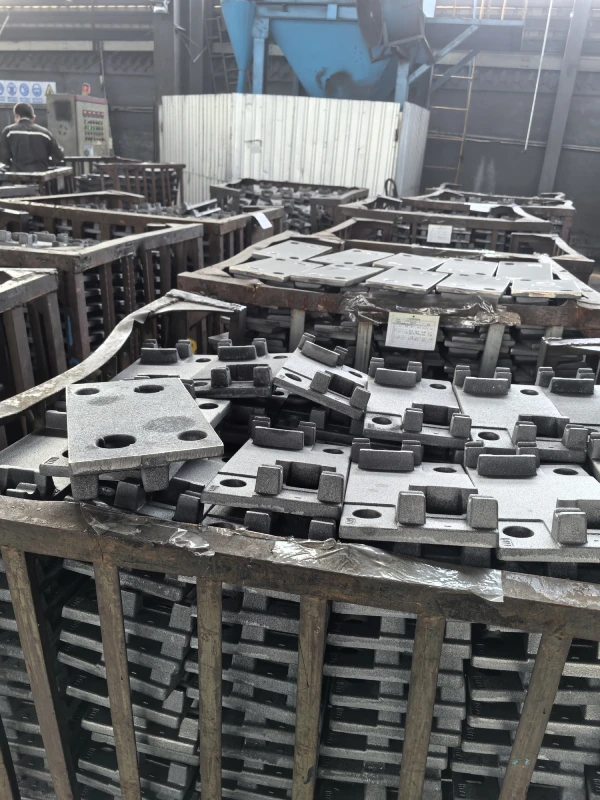

stamp concrete pipe mould bottom ring factory

The Evolution and Significance of Stamp Concrete Pipe Mould Bottom Ring Production

In the construction industry, the demand for robust and reliable materials is ever-increasing. One such material gaining attention is the stamp concrete pipe mould bottom ring, an essential component in the manufacturing of concrete pipes. As our cities continue to expand and require improved infrastructure, understanding the production process, applications, and benefits of these moulds becomes increasingly crucial.

The Role of Concrete Pipe Moulds

Concrete pipes have been indispensable in various civil engineering applications, including drainage systems, sewage disposal, and stormwater management. The moulds used in their production dictate the quality and durability of the final product. Among these, the bottom ring plays a vital role. It serves as the base structure of the concrete pipe, ensuring stability and supporting the weight of the material during both production and installation.

Manufacturing Process of Stamp Concrete Pipe Mould Bottom Rings

The production of stamp concrete pipe mould bottom rings involves several key steps. Firstly, high-quality raw materials, like steel and durable plastics, are selected to create durable moulds that can withstand the pressures of both the casting and curing processes.

1. Design and Engineering The design process is critical, as it determines the dimensions and shape of the ring. Advanced software tools are often utilized to create precise models that ensure an accurate casting process.

2. Fabrication After finalizing the design, the moulds are fabricated. High precision machinery shapes the steel or plastic into the required form, ensuring that all specifications are met. This phase requires skilled technicians who understand the nuances of mould construction.

3. Stamping and Treatment The term “stamp” refers to the process of impressing patterns into the mould material. This not only enhances the aesthetic appeal of the concrete pipes but also contributes to their structural integrity. Following stamping, the moulds undergo treatments to ensure they can endure repeated use without degradation.

4. Quality Control Throughout the manufacturing process, strict quality control measures are implemented. Testing the strength, durability, and accuracy of each mould ensures that only the best products are used in concrete pipe production.

Advantages of Using Stamp Concrete Pipe Mould Bottom Rings

stamp concrete pipe mould bottom ring factory

Utilizing stamp concrete pipe mould bottom rings offers numerous advantages for manufacturers and construction projects

1. Enhanced Durability The robust materials used in the production of these moulds result in pipes that can withstand harsh environmental conditions. This is crucial, especially in applications like sewage systems where corrosion resistance is essential.

2. Cost-Effectiveness By producing high-quality moulds that can be reused multiple times, manufacturers reduce costs associated with material waste and labor. This efficiency translates into lower production costs and a more competitive market position.

3. Customizability The ability to design and manufacture moulds tailored to specific project requirements allows for flexibility in construction. This customizability ensures that different sizes and shapes can be accommodated, meeting a wide array of infrastructure needs.

4. Aesthetic Versatility The stamping process allows for various textures and designs to be incorporated into the moulds, making it possible to create visually appealing concrete pipes without sacrificing functionality.

The Future of Concrete Pipe Mould Manufacturing

As the demand for sustainable and efficient infrastructure grows, the manufacturing of stamp concrete pipe mould bottom rings is evolving. Innovations such as 3D printing and advanced polymer materials are beginning to make waves in this industry. These technologies hold the potential to further enhance the precision and durability of moulds while reducing production times.

Furthermore, with an increased focus on environmental sustainability, manufacturers are seeking eco-friendly materials and practices. This trend is shaping the future of concrete pipe production, leading to more sustainable construction practices and reduced carbon footprints.

Conclusion

The stamp concrete pipe mould bottom ring is a small but critical element in the construction landscape. Understanding its production process, advantages, and future trends is essential for stakeholders in the industry. As communities around the world continue to grow, investing in robust infrastructure equipped with high-quality components like stamped concrete pipes will be pivotal in creating resilient, sustainable urban environments.

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025

-

Buy Cast Iron Pipe: Premium Ductile Iron & Drain Solutions

NewsAug.07,2025