დეკ . 21, 2024 20:35 Back to list

stamping concrete pipe mold bottom ring factory

The Role of Stamping Concrete Pipe Mold Bottom Rings in Modern Infrastructure

In the realm of modern infrastructure, the components that ensure the durability and functionality of various structures are often underestimated. One such pivotal yet often overlooked element is the bottom ring of concrete pipe molds, specifically those manufactured through stamping processes. This article delves into the significance of stamping concrete pipe mold bottom rings, exploring their production, benefits, and application.

Understanding Concrete Pipe Mold Bottom Rings

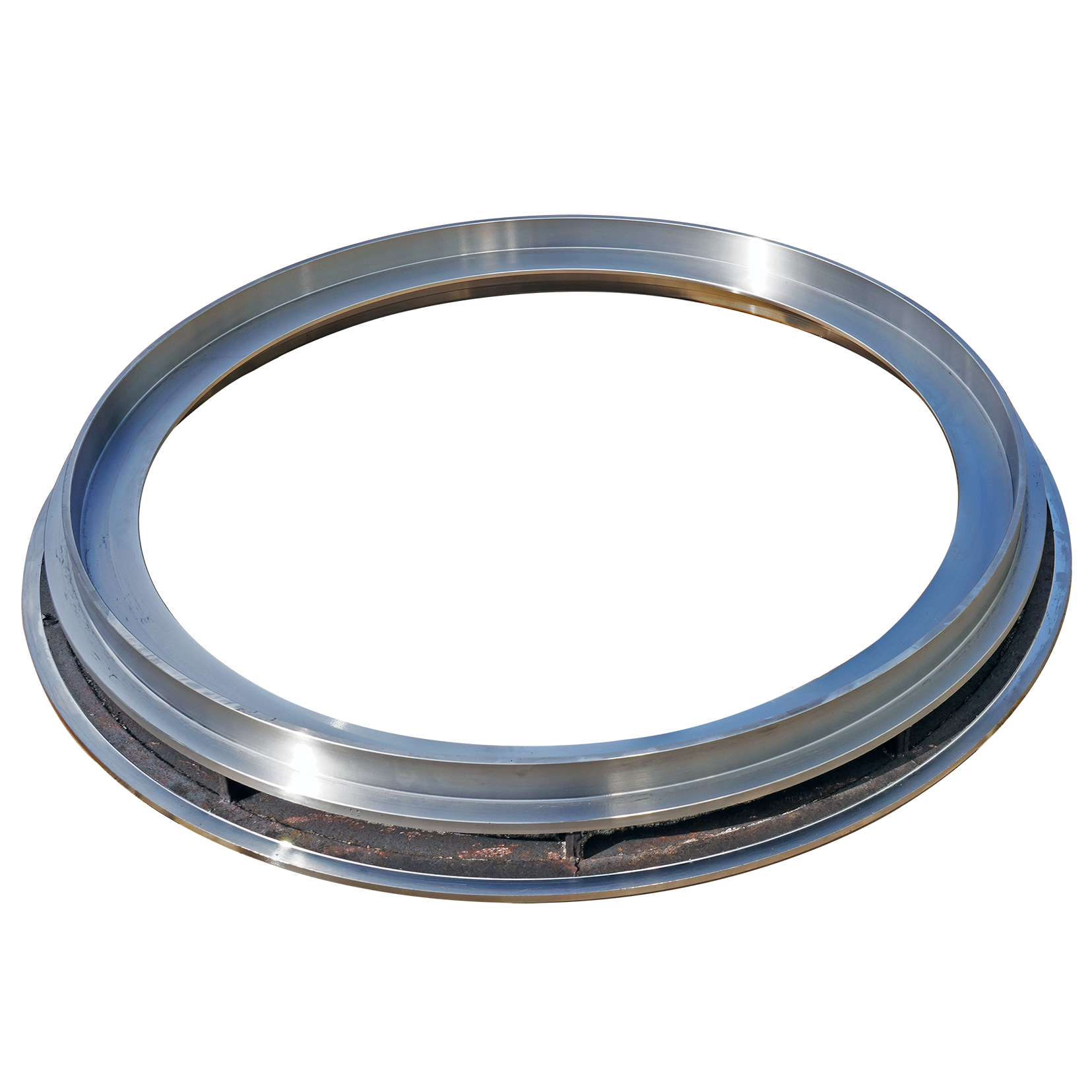

Concrete pipe molds are essential in the manufacturing of concrete pipes that serve a myriad of purposes, from sewage systems and stormwater management to irrigation and drainage solutions. The bottom ring of these molds plays a critical role in determining the dimensional accuracy and structural integrity of the finished product. Typically made from strong materials such as steel or ductile iron, these bottom rings must withstand high pressure and produce precise shapes during the curing process.

The Stamping Process

The production of these bottom rings often employs a stamping technique, a method known for its effectiveness in shaping metal parts with high precision and efficiency. In a stamping factory, sheets of metal are mechanically pressed into molds to form the desired shape of the bottom rings. This method not only enhances precision but also allows for the mass production of components, which is crucial in meeting the high demand for concrete pipes in construction and civil engineering projects.

One of the main advantages of the stamping process is its ability to produce intricate designs, which can include features such as grooves or ribs. These features are important because they provide additional strength and facilitate better bonding with the concrete. Moreover, the stamping method leads to reduced material waste, making it a cost-effective solution in the manufacturing process.

Benefits of Stamping Concrete Pipe Mold Bottom Rings

1. Durability Stamped bottom rings are recognized for their resilience. They can withstand the heavy loads and pressures associated with underground installations, contributing to the longevity of the concrete pipes themselves.

stamping concrete pipe mold bottom ring factory

2. Cost-Effectiveness By facilitating mass production with minimal material waste, stamping molds reduce overall manufacturing costs. This efficiency translates into savings for builders and infrastructure developers.

3. Precision Engineering The stamping process allows for high-precision manufacturing, ensuring that each bottom ring fits perfectly into its corresponding mold. This accuracy is crucial for maintaining the quality of the final concrete pipes.

4. Rapid Production With the capabilities of modern stamping machinery, production rates can be significantly increased, allowing for faster project completions. This is particularly beneficial in large-scale construction projects where time is of the essence.

5. Customization Stamping processes can be easily adjusted to create customized bottom rings that meet specific project requirements. This adaptability is essential in handling diverse infrastructural needs.

Applications in Infrastructure

The applications of concrete pipes with stamped bottom rings are vast. They are indispensable in constructing sewer systems, culverts, and drainage systems, as well as in agricultural settings for irrigation and water management. The strength and reliability of these pipes ensure that they can handle the varying pressures and environmental conditions they encounter.

Furthermore, as cities continue to grow and evolve, the demand for efficient and durable infrastructure solutions increases. Stamped concrete pipe mold bottom rings, with their myriad of benefits, are poised to play a critical role in meeting this demand.

Conclusion

In summary, the stamping of concrete pipe mold bottom rings represents an essential aspect of modern construction practices. Their precision, durability, and cost-effectiveness make them integral to the infrastructure of our cities and communities. As the construction industry embraces innovative manufacturing techniques, the importance of these seemingly minor components cannot be overstated. They not only contribute to the quality of concrete pipes but also to the overall resilience and functionality of urban infrastructure systems.

-

Centrifugally Cast Iron Water Main Pipe | Ductile Iron Solutions

NewsAug.24,2025

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025