Жел . 30, 2024 17:46 Back to list

Exporters of Cast Machinery for Coal Mining Industry and Equipment

The Role of Casting in Coal Mining Machinery Insights into Exporters

Coal mining has long been a cornerstone of the global energy sector, playing a critical role in electricity generation and industrial processes. With demand soaring in various parts of the world, the machinery associated with coal mining is more vital than ever. Among the fundamental components of this machinery is casting, an indispensable manufacturing process used by exporters around the globe. This article delves into the significance of casting in coal mining machinery and highlights the key players in this niche market.

Understanding Casting in Coal Mining Machinery

Casting is a manufacturing process in which liquid material is poured into a mold to create a specific shape upon cooling and solidifying. In the context of coal mining machinery, this technique is used to produce essential components such as gearboxes, excavator buckets, and conveyor systems. These parts must be durable, efficient, and capable of withstanding harsh environments and physical wear.

The casting process typically involves several stages including pattern-making, melting, pouring, and finishing. Two prevalent casting methods used in the industry are sand casting and investment casting. Sand casting is often favored due to its cost-effectiveness and ability to produce large components. Conversely, investment casting, though more expensive, provides superior precision and surface finish, making it suitable for intricate designs.

The Importance of Quality and Innovation

The quality of casting directly impacts the overall performance and longevity of coal mining machinery. Substandard components can lead to equipment failure, increased maintenance costs, and, ultimately, production downtime. Therefore, leading exporters are focused on quality assurance and stringent testing processes to ensure that their products meet global industry standards.

Innovation also plays a pivotal role in the casting of coal mining machinery components. Advances in technology such as Computer Numerical Control (CNC) machining and 3D printing are revolutionizing the casting process, allowing for greater precision and reduced production times. Additionally, the use of advanced alloys and composite materials enhances the strength and durability of cast components, addressing the ever-increasing demands of the industry.

Global Exporters of Coal Mining Machinery Castings

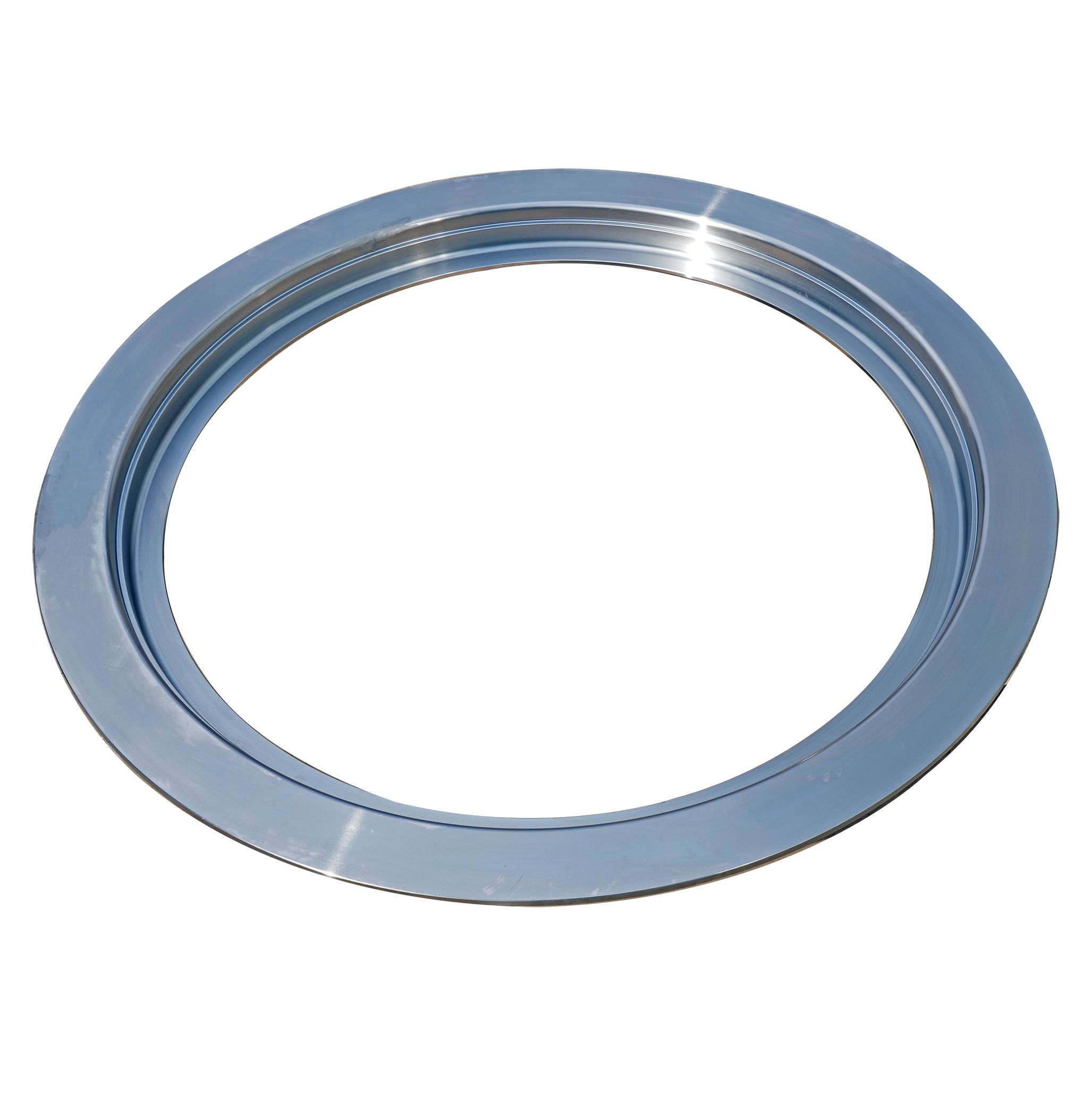

coal minning machinery casting exporters

Several countries are recognized as key exporters of coal mining machinery castings, each contributing uniquely to the global market. Countries like China, India, and the United States are notable leaders due to their vast resources, industrial infrastructure, and expertise in metallurgy.

China is perhaps the largest producer and exporter of coal mining machinery castings, largely due to its robust manufacturing capabilities and cost advantages. The country's emphasis on developing advanced technologies has also enabled it to become a primary supplier to various countries in Asia, Europe, and Africa.

India has emerged as a competitive player in the market, driven by its growing energy demands and significant investments in infrastructure. Indian exporters are increasingly focusing on developing innovative products that cater to the specific needs of clients in the coal mining sector.

The United States stands out for its emphasis on quality and compliance with stringent safety standards. U.S. exporters often focus on producing high-value, customized components that meet the exact specifications of their clients. This has established a strong reputation for U.S. castings in global markets.

Challenges Faced by Exporters

Despite the promising prospects, coal mining machinery casting exporters face several challenges. Fluctuating raw material prices, increasing energy costs, and environmental regulations can significantly impact profitability. Additionally, the global shift towards renewable energy sources is compelling many exporters to adapt their production processes and explore alternative manufacturing avenues.

Moreover, geopolitical tensions and trade agreements can also pose risks to exporters. Keeping abreast of changing regulations and maintaining compliance with international standards is crucial to sustaining competitiveness.

Conclusion

Casting plays an integral role in the production of coal mining machinery, with exporters around the world striving to deliver high-quality and innovative solutions to meet the demands of this essential industry. As the global landscape continues to evolve, so too will the strategies employed by these exporters to navigate challenges and seize opportunities for growth. The future of coal mining machinery, underpinned by advanced casting techniques, remains crucial to supporting the world's energy needs sustainably and efficiently.

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025

-

Buy Cast Iron Pipe: Premium Ductile Iron & Drain Solutions

NewsAug.07,2025