Жел . 03, 2024 13:12 Back to list

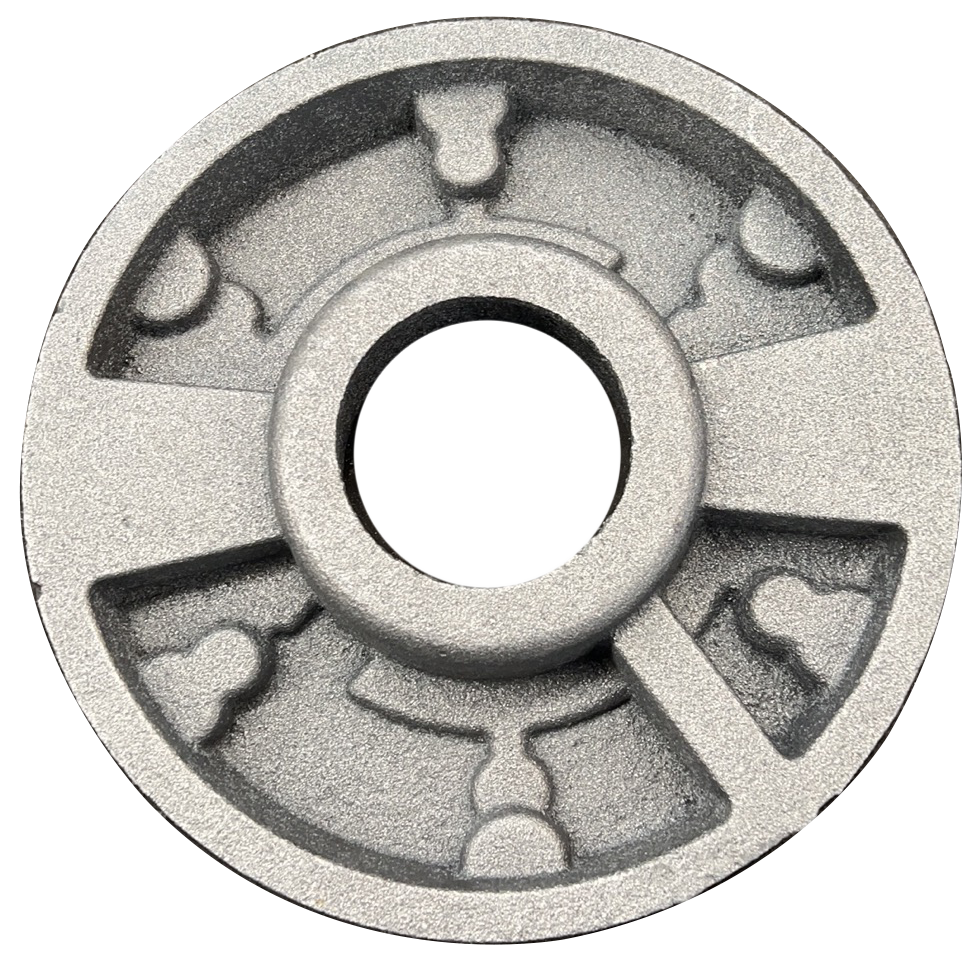

stamp concrete pipe mould bottom ring exporter

The Role of Stamp Concrete Pipe Mould Bottom Rings in Export Markets

In the realm of construction and infrastructure development, the importance of high-quality materials and components cannot be overstated. One such critical component is the bottom ring of stamp concrete pipe moulds. As the construction industry continues to expand globally, the demand for reliable exporters of these products has been on the rise. This article explores the significance, features, applications, and export trends of stamp concrete pipe mould bottom rings.

Understanding Stamp Concrete Pipe Moulds

Stamp concrete pipe moulds are essential in the production of concrete pipes used across various applications, including drainage, sewage systems, and irrigation channels. The bottom ring of these moulds plays a pivotal role in shaping and supporting the concrete during the curing process. It ensures the integrity of the pipe during manufacturing and helps achieve a uniform structure that meets industry standards.

Significance of Bottom Rings

The bottom ring of a stamp concrete pipe mould is designed to endure significant stress during the casting process. Its robust construction ensures that the shape of the pipe is maintained, preventing any deformations that could compromise the functionality of the pipes. This component is crucial for ensuring the longevity and durability of the finished products, which directly impacts the overall quality of infrastructure projects.

Features of High-Quality Bottom Rings

High-quality bottom rings are characterized by several key features. First and foremost, they should be made from durable materials that can withstand the rigorous demands of concrete production. Common materials include high-grade steel, which provides both strength and longevity. Additionally, these rings must be designed to allow for the easy release of the cured concrete, minimizing the risk of surface damage or defects.

Another important feature is the precision of design. Bottom rings should be manufactured with exact measurements to ensure compatibility with various mould sizes and configurations. This precision not only enhances the ease of use but also increases the efficiency of the production process.

Applications in Various Industries

stamp concrete pipe mould bottom ring exporter

The applications of stamp concrete pipe mould bottom rings extend beyond traditional construction. They are used in manufacturing pipes for telecommunications, electrical conduits, and other specialized infrastructures. With the rise of smart cities and urban development, the demand for reliable and efficient pipe systems has soared, further driving the need for robust mould components.

Moreover, as economies develop, increased urbanization leads to a greater necessity for effective wastewater management systems. Bottom rings play a vital role in ensuring that the concrete pipes used in these systems are of high quality, capable of withstanding harsh environmental conditions and heavy loads.

The Export Market

As global demand for construction materials continues to grow, the export market for stamp concrete pipe mould bottom rings is becoming increasingly competitive. Countries with advanced manufacturing capabilities, such as China, Germany, and the United States, are leading exporters. These countries benefit from established supply chains, skilled labor forces, and technological advancements in manufacturing processes.

Exporters in this domain must adhere to international standards and regulations to ensure their products meet the specific requirements of different markets. This includes complying with quality certifications, environmental standards, and local regulations, which can vary significantly from one country to another.

Challenges and Opportunities

Despite the growing demand and opportunities in the export market, exporters face several challenges. Fluctuating raw material prices, trade tariffs, and logistical issues can impact profitability and competitiveness. Additionally, the emphasis on sustainability may require manufacturers to adapt their processes to produce eco-friendly products.

However, these challenges also present opportunities for innovation. Companies that invest in research and development can create advanced mould systems that not only meet market demands but also contribute to sustainability efforts. The adoption of new technologies, such as automation and smart manufacturing techniques, can enhance production efficiency and product quality.

Conclusion

The stamp concrete pipe mould bottom ring is a crucial component in the construction industry, impacting the quality and durability of concrete pipes used in various applications. As global demand continues to rise, exporters play an essential role in providing high-quality mould components. By focusing on material durability, precision engineering, and adapting to market challenges, these exporters can capitalize on the growing opportunities within the international construction landscape. The future of stamp concrete pipe mould bottom rings appears promising, with potential for continued growth and innovation in the global marketplace.

-

OEM Cast Silicon Aluminum Alloy Heat Exchanger | Custom & High Performance

NewsAug.25,2025

-

Centrifugally Cast Iron Water Main Pipe | Ductile Iron Solutions

NewsAug.24,2025

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025