សីហា . 10, 2025 00:40 Back to list

Centrifugally Cast Iron Water Main Pipes for Reliability

The Enduring Legacy and Modern Application of Cast Iron Water Main Pipes

In the vast landscape of modern infrastructure, the choice of materials for critical utilities, especially for water distribution, is paramount. Among the various options, the cast iron water main pipe stands as a testament to durability, reliability, and time-tested performance. For centuries, cast iron has been the backbone of municipal water supply networks, industrial fluid transport, and wastewater systems, largely due to its inherent strength, corrosion resistance, and impressive longevity. Its widespread adoption across diverse sectors, from the rigorous demands of petrochemical processing to the essential needs of urban water management and the specific requirements of metallurgy, underscores its foundational role. This material's continued relevance in an era of rapid technological advancement speaks volumes about its intrinsic value and the continuous innovation in its manufacturing processes. Modern developments, including advanced coating technologies and refined casting techniques like centrifugally cast iron, have further enhanced the performance characteristics of these pipes, ensuring they meet the stringent demands of contemporary infrastructure projects. Understanding the multifaceted advantages of these pipes, from their robust technical specifications to their ecological benefits, is crucial for B2B decision-makers and technical professionals seeking optimal, long-term solutions for their fluid conveyance challenges. This comprehensive overview delves into the intricate details of its manufacturing, technical superiority, diverse applications, and strategic considerations for procurement, emphasizing the value it delivers in terms of energy efficiency and superior corrosion resistance across various operational environments.

The evolution of the cast iron pipe industry has been marked by a relentless pursuit of engineering excellence, moving from traditional sand casting methods to highly automated and precise techniques such as centrifugal casting, which produces superior centrifugally cast iron pipe. This technological progression has not only improved the physical properties of the pipes, such as tensile strength and ductility, but also their consistency and overall quality, making them more resilient to the stresses of modern operating conditions. When considering to buy cast iron pipe, it is essential to look beyond the initial cost and evaluate the total cost of ownership, which includes factors like installation ease, maintenance requirements, and an exceptionally long service life that often extends well over 100 years. The robust nature of these pipes also makes them an excellent choice for a wide array of applications beyond just water mains, including their use as cast drain pipe, for storm water management, and even in specialized industrial settings requiring high pressure or abrasive fluid transport. Furthermore, the industry has witnessed significant strides in developing specialized variants like cast ductile iron pipe, which offers enhanced flexibility and impact resistance, broadening the scope of applications where cast iron materials can be effectively deployed. These advancements collectively reinforce the position of cast iron pipes as a preferred solution for critical infrastructure, offering a blend of proven reliability and forward-looking innovation.

Precision Manufacturing: The Core of Cast Iron Water Main Pipe Excellence

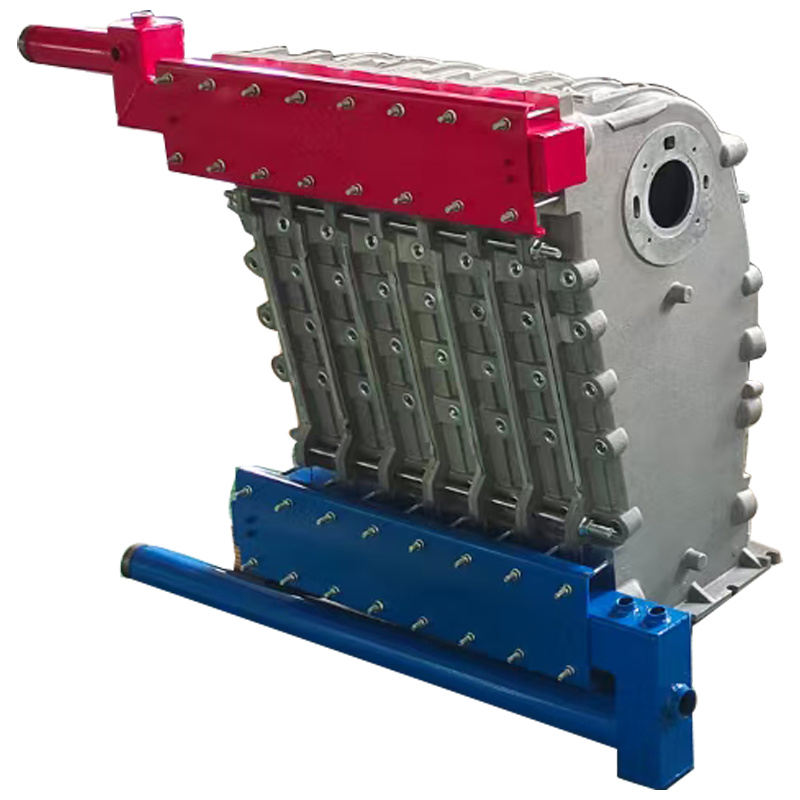

The manufacturing process of a cast iron water main pipe is a sophisticated orchestration of metallurgy, engineering, and quality control, culminating in a product renowned for its longevity and performance. The journey begins with the meticulous selection of raw materials, primarily high-grade pig iron, steel scrap, and various alloying elements, all chosen to achieve specific metallurgical properties. These materials are then melted in induction furnaces or cupola furnaces at extremely high temperatures, ensuring a homogeneous molten iron mixture. This molten metal is then precisely transferred to the heart of the casting process: centrifugal casting. In this method, the molten iron is poured into a rapidly rotating metal mold. The centrifugal force evenly distributes the molten metal against the inner surface of the mold, creating a dense, uniform, and concentric pipe wall free from inclusions and porosity. This method is crucial for producing high-quality centrifugally cast iron and is a cornerstone of modern pipe manufacturing, significantly enhancing the structural integrity and smooth inner surface of the pipe. The controlled cooling rate after casting is also vital, influencing the microstructure of the iron and, consequently, its mechanical properties. This precision in cooling prevents stress cracking and ensures optimal material hardness and strength. Following casting, the pipes undergo an annealing process, where they are heated to specific temperatures and then slowly cooled. This heat treatment is critical for relieving internal stresses, improving ductility, and enhancing machinability, which are vital for subsequent processing like tapping and drilling in the field. The result is a robust centrifugally cast iron pipe that meets stringent performance criteria for pressure applications.

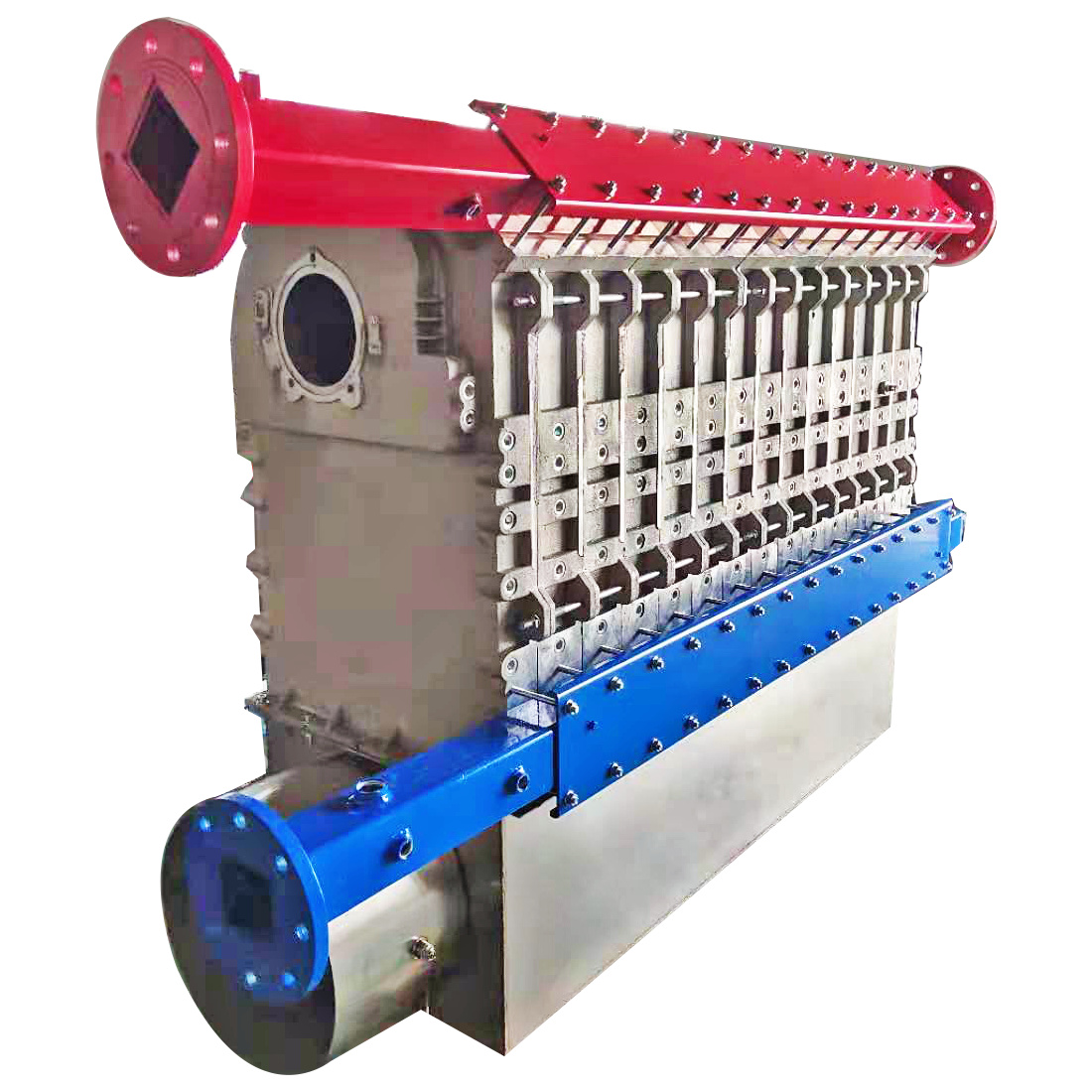

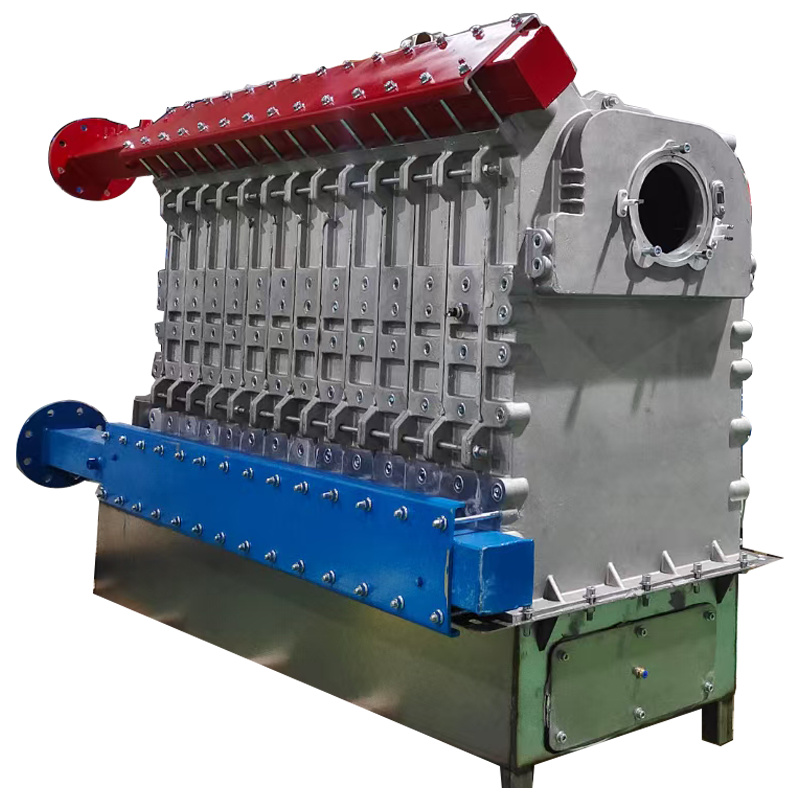

Post-annealing, the pipes undergo a series of finishing operations, including precise machining of the pipe ends to create bell and spigot joints or flanged connections, ensuring tight and reliable seals during installation. This stage often involves CNC machining for high precision, guaranteeing compatibility with various fitting systems. Surface preparation is equally important, as the pipes are thoroughly cleaned to remove any scale or impurities before applying internal and external coatings. These coatings, such as cement mortar lining for internal surfaces and zinc/bituminous coatings or fusion-bonded epoxy for external protection, are critical for enhancing the pipe's resistance to corrosion and tuberculation, thereby extending its service life and maintaining optimal flow characteristics, which contribute to significant energy savings over the pipe's operational lifespan. Every batch of cast iron water main pipe undergoes rigorous inspection and testing. This includes hydrostatic pressure testing to verify its structural integrity and leak resistance under specified working pressures, often exceeding operational demands to provide a safety margin. Dimensional checks, visual inspections for surface defects, and metallurgical tests to confirm material composition and mechanical properties are also standard. Adherence to international standards such as ISO 2531 for ductile iron pipes, ANSI/AWWA C151/A21.51 for ductile iron pressure pipe and fittings, and various other national and industry-specific standards is strictly maintained. This comprehensive quality assurance process guarantees that each pipe leaving the factory gates meets the highest benchmarks for performance, safety, and longevity, making them suitable for demanding applications in petrochemical, metallurgy, and water supply and drainage industries.

Technical Parameters and Specifications: The Backbone of Performance

The robust performance of a cast iron water main pipe is directly attributable to its meticulously defined technical parameters and adherence to strict specifications. These parameters dictate the pipe's suitability for various applications, its resistance to internal and external forces, and its overall reliability. Key among these specifications are the nominal diameter (DN), which refers to the approximate inner diameter, and the corresponding cast iron outside diameter (OD), which is crucial for determining compatibility with fittings and trenching requirements. Pressure ratings are another critical specification, typically expressed in terms of nominal pressure (PN) or working pressure, and are a direct measure of the pipe's ability to withstand internal fluid pressure. For instance, common pressure classes for ductile iron pipes can range from PN10 to PN40, signifying capabilities for 10 to 40 bar of internal pressure, respectively. Wall thickness, which correlates with the pressure class, is also a vital parameter, ensuring the structural integrity of the pipe under specified loads and pressures. The standard length of pipes, commonly 6 meters (20 feet) in many regions, impacts logistics, installation efficiency, and the number of joints required for a given pipeline length. Material composition, while generally iron, includes precise percentages of carbon, silicon, manganese, phosphorus, sulfur, and magnesium (for ductile iron), each contributing to the final mechanical properties, such as tensile strength, yield strength, and elongation. For example, ductile iron's higher ductility compared to grey cast iron is achieved by adding magnesium during the casting process, transforming the graphite flakes into spheroidal nodules, which significantly improves its resistance to fracture.

Coatings and linings are integral to the pipe's long-term performance, particularly in aggressive environments. Internal cement mortar linings, conforming to standards like ISO 4179 or AWWA C104/A21.4, prevent tuberculation, maintain flow capacity, and protect against internal corrosion from water-borne contaminants. External coatings, such as metallic zinc primer with a finishing layer of bituminous or epoxy paint (ISO 8179) or fusion-bonded epoxy (AWWA C116/A21.16), offer superior protection against soil corrosivity, contributing significantly to the pipe's extensive service life. Joint types, including push-on joints with rubber gaskets (Tyton type), mechanical joints, flanged joints, and restrained joints, are also critical specifications, influencing installation speed, flexibility, and resistance to thrust forces. Each joint type is designed for specific application requirements, ensuring a leak-proof and stable system. When one decides to buy cast iron pipe, understanding these parameters is fundamental to selecting the correct product for the intended application, whether it's for high-pressure municipal water supply or low-pressure industrial drainage. The overall structural design of the pipe, including its ability to withstand external loads from soil and traffic, is calculated based on these specifications, ensuring that the cast iron water main pipe maintains its integrity underground for decades. Below is a detailed table summarizing typical technical specifications for common sizes of ductile iron pipes, which have largely superseded grey cast iron for main pipe applications due to their superior properties, representing the cutting edge in cast iron pipe technology.

| Parameter | DN (Nominal Diameter) | OD (Cast Iron Outside Diameter) | Wall Thickness (mm) | Pressure Class (PN/Bar) | Standard Length (m) | Internal Lining | External Coating |

|---|---|---|---|---|---|---|---|

| Ductile Iron Pipe | 100-200 | 118-216 | 4.5-6.0 | PN10-PN40 | 6 | Cement Mortar | Zinc + Bitumen/Epoxy |

| Ductile Iron Pipe | 300-500 | 318-518 | 6.0-7.7 | PN10-PN40 | 6 | Cement Mortar | Zinc + Bitumen/Epoxy |

| Ductile Iron Pipe | 600-1000 | 630-1030 | 8.0-10.0 | PN10-PN25 | 6 | Cement Mortar | Zinc + Bitumen/Epoxy |

Versatile Applications and Unparalleled Advantages of Cast Iron Pipes

The adaptability and robust characteristics of cast iron water main pipe make it an indispensable component across a multitude of industries and applications, extending far beyond conventional municipal water supply systems. Its inherent strength and resilience make it ideal for high-pressure water distribution networks, ensuring consistent and reliable delivery to urban and rural populations. In wastewater management, the pipe's resistance to abrasion and chemical degradation from effluents positions it as a superior choice for sewer force mains and gravity sewers, including its widespread use as cast drain pipe. Industrial sectors, particularly petrochemical, mining, and manufacturing, rely on cast iron pipes for transporting various fluids, slurries, and even corrosive chemicals under challenging conditions. The material's ability to withstand external loads, such as soil overburden and traffic vibrations, is crucial in these demanding environments, minimizing the risk of pipe failure and ensuring operational continuity. Furthermore, the excellent thermal conductivity and durability of cast iron make it suitable for specialized applications like cast iron heating pipes in certain industrial or district heating systems where heat transfer and structural integrity are critical. Its long service life, often exceeding 100 years, significantly reduces the lifecycle costs associated with replacement and maintenance, offering substantial economic advantages for long-term infrastructure planning.

Beyond its primary function in water and wastewater, cast iron conduit is also utilized for protecting electrical cables and communication lines underground, offering robust physical protection against external damage and environmental factors. The advantages extend to specific niche areas like fire protection systems, where the pipe's high-pressure rating and resistance to damage from ground movement are invaluable. From a technical standpoint, the pipe's smooth internal surface, especially when lined with cement mortar, minimizes friction loss, contributing to energy efficiency in pumping operations by reducing the required pumping head and thereby lowering electricity consumption. The inherent structural strength of centrifugally cast iron pipe provides superior resistance to surge pressures and water hammer effects, which are common issues in extensive pipeline networks and can lead to costly failures in less robust materials. The exceptional corrosion resistance, primarily attributed to the passive film formed on the iron surface and enhanced by advanced external coatings, makes it highly suitable for diverse soil conditions, including aggressive environments. When considering where to buy cast iron pipe or searching for cast iron drain pipes for sale, these intrinsic advantages ensure a wise investment that yields long-term performance and reliability, reducing the need for frequent interventions and repairs. The overall environmental footprint is also favorable, as cast iron is a highly recyclable material, aligning with modern sustainability goals in infrastructure development.

The Evolution and Comparison: From Grey Cast Iron to Ductile Iron Pipe

The history of iron pipes in water infrastructure spans centuries, initially dominated by grey cast iron. While grey cast iron served its purpose admirably for a long time, its inherent brittleness due to the flake-like graphite structure within its matrix presented limitations, especially under dynamic loading conditions or in areas prone to ground movement. The advent of cast ductile iron pipe in the mid-20th century marked a significant leap forward in pipe technology, effectively addressing the shortcomings of its predecessor. Ductile iron is essentially cast iron treated with magnesium, which transforms the graphite within the iron's microstructure from flakes into spherical nodules. This spheroidal graphite structure acts as crack arresters, allowing the material to deform under stress rather than fracturing, thereby imparting significant ductility and impact resistance. This fundamental difference in microstructure is what sets cast ductile iron pipe apart, making it the preferred material for modern cast iron water main pipe applications. Ductile iron pipes typically offer tensile strengths of 420 MPa or more, compared to around 150-250 MPa for grey cast iron, and significantly higher elongation percentages (often over 10% versus less than 1% for grey cast iron). This enhanced ductility translates directly into greater resilience against earth movements, seismic activity, ground settlement, and traffic loads, drastically reducing the risk of pipe breaks and associated service disruptions.

When choosing to buy cast iron pipe, understanding the distinctions between grey and ductile iron is crucial for optimal project outcomes. Ductile iron pipes, often manufactured via the centrifugally cast iron pipe process, benefit from superior wall uniformity and strength, allowing for thinner walls while maintaining comparable or even superior pressure ratings compared to thicker grey cast iron pipes. This reduction in wall thickness means lighter pipes, which translate to easier handling, reduced transportation costs, and faster installation. Furthermore, the greater strength and ductility of cast ductile iron pipe enable it to accommodate larger spans between supports and tolerate higher internal pressures, expanding its utility in diverse and challenging environments. While grey cast iron still finds limited applications, such as for some cast drain pipe uses where high pressure and impact resistance are not primary concerns, ductile iron has become the industry standard for pressure piping in water and wastewater infrastructure globally. Its robust performance under transient pressures, external loads, and its resistance to corrosion through advanced coatings make it a far more reliable and cost-effective solution in the long run. The continued investment in research and development within the ductile iron pipe industry also means ongoing improvements in joint designs, coatings, and overall pipe integrity, further solidifying its position as a leading material for critical infrastructure projects, offering enhanced safety, efficiency, and environmental sustainability.

Strategic Sourcing: Manufacturer Comparison and Customization Solutions

Selecting the right manufacturer when looking to buy cast iron pipe or specifically a cast iron water main pipe is a critical decision that impacts project success, longevity of the infrastructure, and overall cost-efficiency. The market offers a diverse range of manufacturers, each with varying capabilities, quality control protocols, and specialization. A reputable manufacturer will demonstrate adherence to international standards such as ISO 9001 for quality management, ISO 14001 for environmental management, and product-specific certifications like ISO 2531 or AWWA standards. Key factors to consider during manufacturer comparison include their experience in producing centrifugally cast iron pipe, their production capacity, and their track record of timely delivery and customer support. It is essential to assess their raw material sourcing, the rigor of their quality assurance processes – including hydrostatic testing, ultrasonic testing, and metallurgical analysis – and their capability to provide comprehensive material test reports (MTRs) and certificates of conformity. Manufacturers that invest in advanced technology, such as automated casting lines and sophisticated coating facilities, often produce pipes with superior consistency and performance characteristics. Furthermore, a manufacturer's reputation for innovation, such as developing improved internal linings or external coatings for enhanced corrosion protection, can significantly add value to your project, extending the service life of the cast iron water main pipe. Engaging with manufacturers who have a robust R&D department and a clear commitment to continuous improvement ensures access to the latest advancements in pipe technology and materials science.

Customization solutions are increasingly important for large-scale infrastructure projects, where standard pipe sizes and configurations may not always suffice. Leading manufacturers offer extensive customization capabilities, ranging from specific cast iron outside diameter and wall thickness combinations to bespoke internal and external coating systems tailored to unique soil conditions, fluid properties, or environmental regulations. For instance, in highly corrosive soil environments, a manufacturer might recommend a special polyethylene encasement or thicker fusion-bonded epoxy coating in addition to the standard zinc and bitumen. For abrasive fluid transport, specialized internal linings designed for wear resistance might be offered. Custom lengths can also be provided to minimize field cuts and joints, thereby reducing installation time and costs. Furthermore, some projects may require pipes with integrated tracing wires for leak detection, or specific types of restrained joints for areas prone to seismic activity. An expert manufacturer will work closely with engineering teams to understand the precise operational parameters, environmental factors, and project-specific challenges, offering tailored solutions that optimize performance and minimize risks. This consultative approach, coupled with robust manufacturing capabilities, allows for the delivery of pipes that are not just commodities but integral, optimized components of a complex system. When sourcing cast iron drain pipes for sale or any other specialized cast iron conduit, prioritizing manufacturers with proven expertise in providing bespoke solutions ensures that the pipes are perfectly matched to the project’s unique demands, delivering maximum efficiency and long-term value, ultimately reinforcing the project's reliability and sustainability for decades to come.

Real-World Impact: Application Cases and Quality Assurance

The tangible benefits of cast iron water main pipe are best illustrated through its successful deployment in various demanding environments. Consider the “City of Metropolis Water Renewal Project,” where over 50 kilometers of DN600 cast ductile iron pipe were installed to replace aging grey cast iron mains. This project faced challenges including varying soil conditions, high population density requiring minimal disruption, and stringent pressure requirements for fire hydrants. The selection of centrifugally cast iron pipes with external fusion-bonded epoxy coating provided superior corrosion resistance in diverse soil chemistries, while the inherent ductility of the pipes allowed for greater tolerance to ground settlement, a common issue in an old city. The ease of push-on joint installation significantly reduced project timelines and labor costs, leading to an overall 15% reduction in installation time compared to alternative materials. Post-installation hydraulic testing confirmed minimal head loss, translating into substantial long-term energy savings for the municipal water utility. Another compelling case involves a major industrial complex in a highly corrosive coastal environment that required a robust solution for its process water supply. By implementing specialized cast iron water main pipe with a dual-layer internal cement mortar lining and a heavy-duty external polyurethane coating, the client achieved a projected service life exceeding 70 years, significantly mitigating the risk of premature failure due to external corrosion and internal scaling, ensuring uninterrupted plant operations and avoiding costly downtimes associated with pipeline failures. These examples underscore the real-world advantages and the profound impact of choosing high-quality cast iron piping solutions.

Our commitment to quality and excellence in every centrifugally cast iron pipe produced is non-negotiable, aligning with the highest industry standards to guarantee authoritative and trustworthy products. All our manufacturing processes are rigorously controlled and certified to ISO 9001:2015, ensuring consistent quality from raw material intake to final product shipment. Our ductile iron pipes conform strictly to international product standards such as ISO 2531 and EN 545 for water applications, and EN 598 for sewage applications, as well as American Water Works Association (AWWA) standards including AWWA C151/A21.51 and C150/A21.50. Each pipe undergoes multiple stages of stringent quality checks. This includes spectrographic analysis of molten iron to verify chemical composition, mechanical property testing (tensile strength, yield strength, elongation, hardness) on test coupons from each batch, and comprehensive dimensional inspections of cast iron outside diameter, wall thickness, and joint dimensions. Furthermore, every single pipe is subjected to hydrostatic pressure testing at pressures significantly higher than its nominal working pressure to ensure zero leakage and structural integrity. For certain applications, non-destructive testing methods such as ultrasonic testing are employed to detect any internal flaws. Our coatings and linings are also subjected to adhesion tests, thickness measurements, and porosity checks to ensure their long-term effectiveness. These exhaustive testing protocols, coupled with our extensive service history of over two decades in the industry and strategic partnerships with leading engineering firms globally, underscore our authoritative position as a reliable supplier for critical infrastructure projects. When you buy cast iron pipe from us, you are investing in a product backed by verifiable data, rigorous testing, and an unwavering commitment to quality.

Ensuring Trust: FAQs, Delivery, Warranty, and Support

Establishing trust with our clients, particularly in critical infrastructure sectors where reliability is paramount, is fundamental to our operations. We achieve this through transparent processes, clear communication, and robust support systems. Our commitment to trustworthiness begins with addressing common inquiries, ensuring that every client fully understands the product they are procuring, whether it's a standard cast iron water main pipe or a specialized solution.

Frequently Asked Questions (FAQs)

- Q: What is the typical lifespan of a cast iron water main pipe?

A: Modern ductile iron pipes, manufactured to current standards with appropriate coatings and linings, have an estimated service life of 100 years or more, significantly outperforming many alternative materials. This longevity contributes to lower lifecycle costs and reduced infrastructure replacement cycles. - Q: How does cast ductile iron pipe compare to PVC or HDPE pipes in terms of strength and durability?

A: Cast ductile iron pipe offers superior tensile strength, rigidity, and resistance to external loads (e.g., ground settlement, traffic loads) and internal pressures compared to plastic pipes. While PVC/HDPE excel in flexibility and specific chemical resistance, ductile iron is preferred for high-pressure large-diameter mains where structural integrity and longevity under dynamic conditions are critical, such as for a robust cast iron water main pipe. - Q: Are your pipes suitable for aggressive soil conditions?

A: Yes, our pipes are manufactured with standard external zinc coating followed by a bituminous or epoxy topcoat. For highly corrosive environments, we offer enhanced protection options such as polyethylene encasement or thicker fusion-bonded epoxy coatings, extending the pipe's resistance to soil corrosion. - Q: What certifications do your products hold?

A: Our pipes adhere to major international standards including ISO 2531 (for ductile iron pressure pipes), EN 545, EN 598, and relevant AWWA standards (e.g., AWWA C151/A21.51). Our manufacturing facilities are ISO 9001 and ISO 14001 certified, ensuring consistent quality and environmental responsibility. - Q: Can you provide customized cast iron outside diameter or specific lengths?

A: Absolutely. While we offer standard sizes and lengths, we specialize in providing customized solutions for specific project requirements, including non-standard diameters, specialized coatings, and bespoke lengths to minimize on-site cutting and optimize installation. This extends to products like specialized cast iron conduit or cast iron heating pipes.

Delivery Cycle Information

Our streamlined logistics and robust production capabilities ensure efficient and timely delivery of your centrifugally cast iron pipe orders. Standard delivery cycles for common sizes and quantities typically range from 4 to 8 weeks, depending on the volume and specific customization requirements. For large-scale projects or highly specialized orders, a detailed production and delivery schedule will be provided upon order confirmation. We work closely with leading logistics providers to ensure secure and efficient transportation, both domestically and internationally, whether you are looking to buy cast iron pipe for a local project or cast iron drain pipes for sale for export. Expedited options may be available for urgent requirements, subject to production schedules and additional charges. We maintain transparent communication throughout the order fulfillment process, providing regular updates on production status and shipping milestones, so you are always informed about your investment in our cast iron water main pipe products.

Quality Assurance and Warranty Commitment

Every cast iron water main pipe manufactured undergoes a multi-stage quality control process, from raw material inspection to final product testing, ensuring compliance with international standards and our own stringent quality benchmarks. We stand behind the quality and performance of our products with a comprehensive warranty. Our standard warranty covers defects in material and workmanship for a period of 10 years from the date of shipment, provided the pipes are installed and operated in accordance with industry best practices and our recommendations. This warranty underscores our confidence in the durability and reliability of our cast ductile iron pipe products, offering peace of mind to our clients regarding their long-term infrastructure investments. Detailed warranty terms and conditions are provided with every quotation and order, ensuring complete transparency and fostering a strong sense of trustworthiness in our partnership.

Dedicated Customer Support

Our commitment to our clients extends far beyond product delivery. We offer dedicated customer support services to assist with technical queries, installation guidance, and any post-sales support that may be required for your cast iron water main pipe projects. Our team of experienced engineers and technical specialists is available to provide expert advice on pipe selection, system design, and troubleshooting. We believe in building lasting relationships, offering continuous support to ensure the optimal performance and longevity of your pipeline infrastructure. From initial consultation to post-installation assistance, our responsive support team is always ready to help, reinforcing our reputation as a trusted partner in the B2B water and industrial sectors. This holistic approach ensures that when you choose our products, you gain not just a pipe, but a complete solution backed by unparalleled expertise and support, ensuring the success and durability of your critical infrastructure.

Conclusion: The Enduring Value of Cast Iron Water Main Pipes

The journey through the intricate world of cast iron water main pipe reveals a product category that is far from static. Instead, it is a testament to continuous innovation, evolving from basic grey cast iron to the highly engineered and exceptionally resilient cast ductile iron pipe. This evolution, driven by advancements in metallurgical science and manufacturing processes like centrifugally cast iron pipe production, has consistently elevated its performance benchmarks. The enduring value proposition of these pipes lies in their unparalleled combination of longevity, structural integrity, and resistance to diverse environmental and operational challenges. For B2B decision-makers and technical professionals tasked with specifying materials for critical infrastructure, the choice of cast iron water main pipe represents a strategic investment that yields long-term dividends. Its ability to withstand high pressures, external loads, and corrosive conditions, coupled with its proven track record of over a century in service for many installations, translates directly into reduced lifecycle costs, minimal maintenance requirements, and enhanced system reliability. Whether the application calls for robust water distribution networks, efficient wastewater conveyance through cast drain pipe systems, or specialized industrial fluid transport including cast iron conduit, the inherent advantages of cast iron make it a compelling choice. The continuous advancements in coatings, joint technologies, and manufacturing precision further solidify its position as a sustainable and high-performance solution for the future of urban and industrial infrastructure globally. When considering where to buy cast iron pipe, prioritizing quality, adherence to standards, and a manufacturer's expertise in customized solutions will ensure the success and longevity of any project.

"Ductile iron pipe has become the material of choice for water and wastewater applications worldwide due to its superior strength, ductility, impact resistance, and long service life. Its resilient properties make it ideal for challenging environments and critical infrastructure where reliability is paramount." - American Water Works Association (AWWA)

As global infrastructure ages and new developments demand ever more resilient and sustainable solutions, the role of materials like cast iron water main pipe becomes even more critical. The emphasis on energy efficiency, reduced carbon footprints, and circular economy principles favors materials that offer extended service lives and are highly recyclable. Cast iron, with its high recycled content potential and exceptional durability, aligns perfectly with these modern sustainability imperatives. Furthermore, the industry continues to innovate, exploring new alloys, advanced coating materials, and smart pipe technologies that can integrate sensors for real-time monitoring of pipeline integrity and performance, promising an even more robust and intelligent future for cast iron piping systems. This forward-looking approach ensures that the investment in these pipes today will continue to provide reliable service and contribute to resilient infrastructure for generations to come, truly making it a foundational element of any robust fluid conveyance system for municipal, industrial, or even specialized uses like cast iron heating pipes.

References and Further Reading:

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025

-

Buy Cast Iron Pipe: Premium Ductile Iron & Drain Solutions

NewsAug.07,2025

-

Durable Cast Iron Water Main Pipe | Buy Ductile Pipe

NewsAug.06,2025