វិច្ឆិកា . 19, 2024 14:13 Back to list

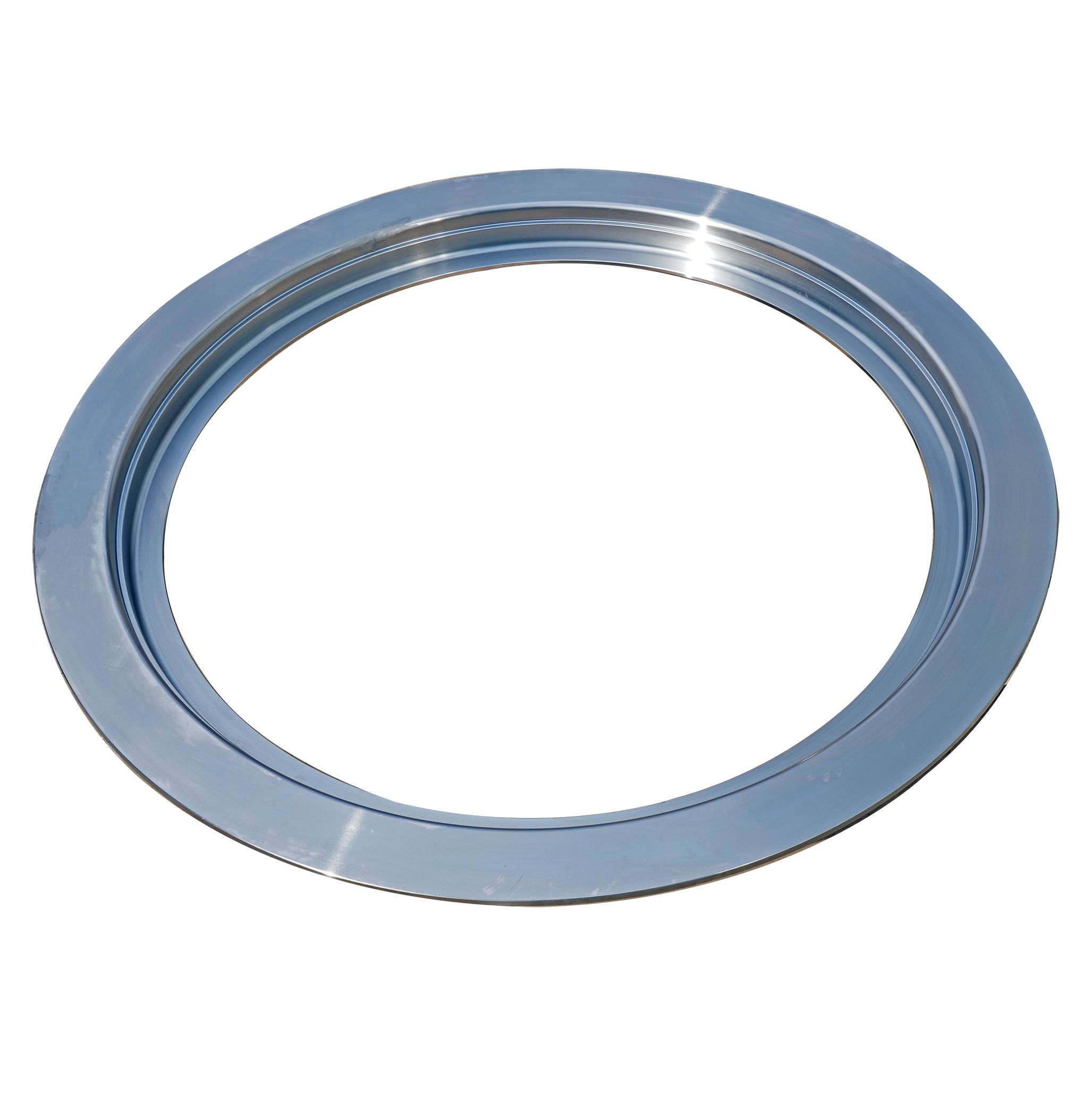

oem steel casting

Understanding OEM Steel Casting A Comprehensive Overview

OEM (Original Equipment Manufacturer) steel casting is a critical component in various industries, including automotive, aerospace, construction, and machinery. This process involves creating metal parts by pouring molten steel into molds, which allows for the production of complex shapes and configurations. The unique properties of steel, coupled with the precision of casting, make it a preferred choice for many applications.

The Basics of Steel Casting

Steel casting is a manufacturing process where molten steel is poured into a mold to form a desired shape after cooling and solidifying. The process can be broken down into several steps

1. Mold Making The first step involves creating a mold that reflects the final product's specifications. Molds can be made from various materials, including metal, sand, or ceramic, depending on the required precision and production volume.

2. Melting Steel Steel is melted in a furnace, reaching temperatures that allow it to be poured easily. Different steel alloys can be used to meet specific performance criteria.

3. Pouring Once the steel is molten, it is poured into the prepared molds. Care must be taken to do this in a controlled manner to avoid defects such as air bubbles or uneven cooling.

4. Cooling After pouring, the steel must be allowed to cool and solidify. This process can be influenced by factors such as the thickness of the casting and the material of the mold.

5. Finishing Once the steel has cooled and solidified, the molds are removed, and the castings are cleaned and finished. This may involve grinding, machining, or surface treatment to achieve the desired final properties.

Advantages of OEM Steel Casting

1. Durability Steel is renowned for its strength and resilience, making it suitable for parts that must withstand heavy loads and extreme conditions.

oem steel casting

2. Design Flexibility The casting process allows for the creation of complex geometries that may be difficult or impossible to achieve with other manufacturing methods.

3. Cost-Effectiveness For large production runs, steel casting can be more economical compared to machining processes, especially when considering material waste.

4. Precision and Consistency Advanced casting technologies, such as precision casting, enable manufacturers to produce parts that meet stringent specifications with minimal deviation.

Applications of OEM Steel Casting

The applications of OEM steel casting are vast, spanning numerous industries. In the automotive sector, cast steel components are used in engines, chassis, and suspension systems, where strength and reliability are paramount. Similarly, in aerospace, steel castings are utilized in critical parts such as landing gear and structural components due to their ability to withstand high stress and fatigue.

The construction industry also heavily relies on steel castings for machinery, tools, and structural supports. Heavy equipment manufacturers often use steel cast components for their toughness and resistance to wear and tear.

Challenges in OEM Steel Casting

Despite its many advantages, OEM steel casting presents challenges. The complexity of the process can lead to defects such as porosity, shrinkage, or warping if not carefully controlled. Additionally, the environmental impact of steel production, particularly in terms of carbon emissions, is a growing concern within the industry.

To address these challenges, manufacturers are increasingly adopting advanced technologies and sustainable practices. Techniques such as 3D printing of molds are emerging, allowing for greater design freedom while reducing waste. Furthermore, the use of recycled steel in casting processes is becoming more prevalent, contributing to a circular economy.

Conclusion

OEM steel casting remains an indispensable manufacturing process that supports various industries with high-quality, durable components. Understanding the intricacies of this process—and its advantages and challenges—can empower businesses to make informed decisions about their manufacturing needs. As technology advances and sustainability becomes a priority, the future of OEM steel casting looks promising, offering enhanced capabilities and innovative solutions to meet the demands of modern engineering.

-

Premium Cast Iron Water Main Pipe for Robust Infrastructure

NewsAug.27,2025

-

A-Rated Cast Aluminum Boilers: High-Efficiency Condensing Gas & LPG

NewsAug.26,2025

-

OEM Cast Silicon Aluminum Alloy Heat Exchanger | Custom & High Performance

NewsAug.25,2025

-

Centrifugally Cast Iron Water Main Pipe | Ductile Iron Solutions

NewsAug.24,2025

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025