វិច្ឆិកា . 14, 2024 14:11 Back to list

sand casting suppliers

Understanding Sand Casting Suppliers The Backbone of the Foundry Industry

Sand casting, one of the oldest and most versatile metal forming processes, remains a prominent method used in various industries today. This process allows for the production of complex geometries and custom metal parts that are essential for manufacturing. At the heart of this process are sand casting suppliers, who provide the necessary materials, equipment, and expertise to support foundries and manufacturers in achieving high-quality castings.

What is Sand Casting?

Sand casting involves creating a mold from sand and a binding agent. This mold is then filled with molten metal, which solidifies to form the desired shape. The advantages of sand casting include its ability to produce large parts, its adaptability to a wide range of metals (such as aluminum, iron, and copper), and the relative low cost of materials. Sand molds can also be reused multiple times, adding to the process's efficiency.

The Role of Sand Casting Suppliers

Sand casting suppliers play a crucial role in this industry by supplying various materials, tools, and equipment necessary for the casting process. Their offerings typically include

1. Casting Sands The primary material in sand casting, suppliers offer different grades of sands, including silica sand, green sand, and specialty sands tailored for specific applications. The choice of sand affects the final product's quality, including its surface finish and dimensional accuracy.

2. Binders Sand needs to be bound together to form a mold. Suppliers provide various binder materials such as clay, resin, and chemical binders. These ensure that the sand retains its shape under pressure and can withstand the temperature of molten metal.

3. Additives To enhance the properties of the mold and core sands, suppliers may also provide chemical additives. These can improve the flow characteristics of the sand, increase resistance to thermal shock, and enhance the surface finish of the final casting.

4. Casting Equipment Suppliers also offer equipment needed for the sand casting process, including molding machines, core making equipment, and pouring systems. Such machinery can be crucial for increasing efficiency and maintaining consistent quality in production.

sand casting suppliers

5. Technical Support and Expertise Many sand casting suppliers provide not only materials but also technical support. This includes assistance with process design, material selection, and troubleshooting common issues in the casting process. Their expertise can be invaluable for manufacturers seeking to optimize their casting operations.

Choosing the Right Sand Casting Supplier

As the demand for sand casting continues to grow, choosing the right supplier becomes critical for foundries and manufacturers. Here are some factors to consider

1. Quality of Materials Look for suppliers who provide high-quality sands and binders that comply with industry standards. The quality of materials directly affects the final product's performance and durability.

2. Product Range A supplier that offers a wide range of products can be advantageous. This ensures that manufacturers can source all necessary materials from a single provider, simplifying procurement and reducing lead times.

3. Technical Support Opt for suppliers that provide strong technical support. Their expertise can help you address specific challenges, optimize your processes, and improve your final product quality.

4. Reputation and Reliability Research suppliers to find those with a solid reputation in the industry. Customer reviews, case studies, and references can provide insight into a supplier's reliability and service quality.

5. Delivery and Logistics Assess the supplier's ability to meet your delivery timelines. Timely delivery is crucial for minimizing production delays and maintaining operational efficiency.

Conclusion

In the world of manufacturing, the importance of reliable sand casting suppliers cannot be overstated. They provide the foundational elements necessary for successful casting operations, enabling manufacturers to produce high-quality components efficiently. As the industry continues to evolve, the collaboration between manufacturers and suppliers will remain vital, driving innovations and improvements in the sand casting process. By carefully selecting the right supplier, businesses can not only streamline their production processes but also enhance the quality and competitiveness of their offerings in the marketplace.

-

Premium Cast Iron Water Main Pipe for Robust Infrastructure

NewsAug.27,2025

-

A-Rated Cast Aluminum Boilers: High-Efficiency Condensing Gas & LPG

NewsAug.26,2025

-

OEM Cast Silicon Aluminum Alloy Heat Exchanger | Custom & High Performance

NewsAug.25,2025

-

Centrifugally Cast Iron Water Main Pipe | Ductile Iron Solutions

NewsAug.24,2025

-

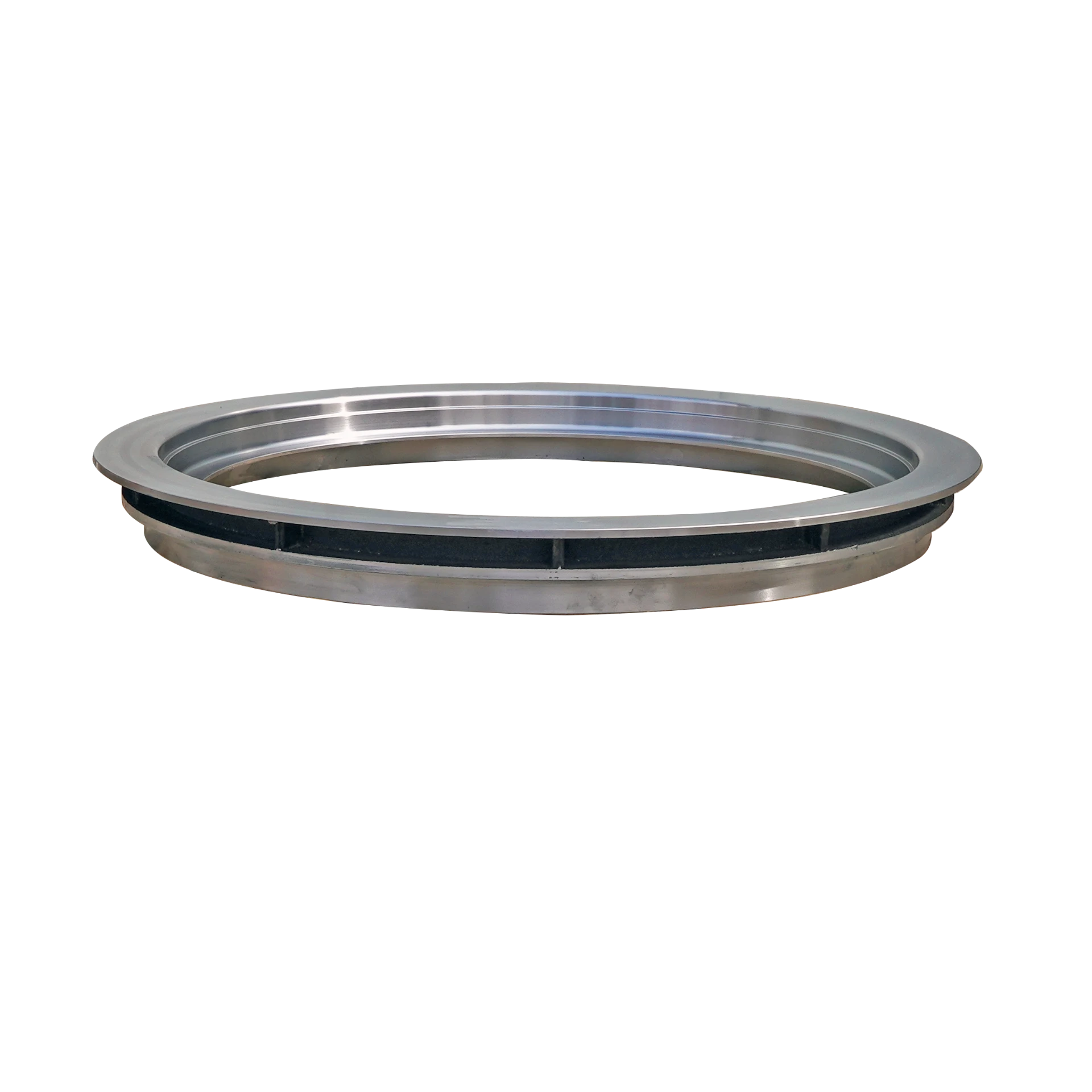

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025