ನವೆಂ . 29, 2024 10:22 Back to list

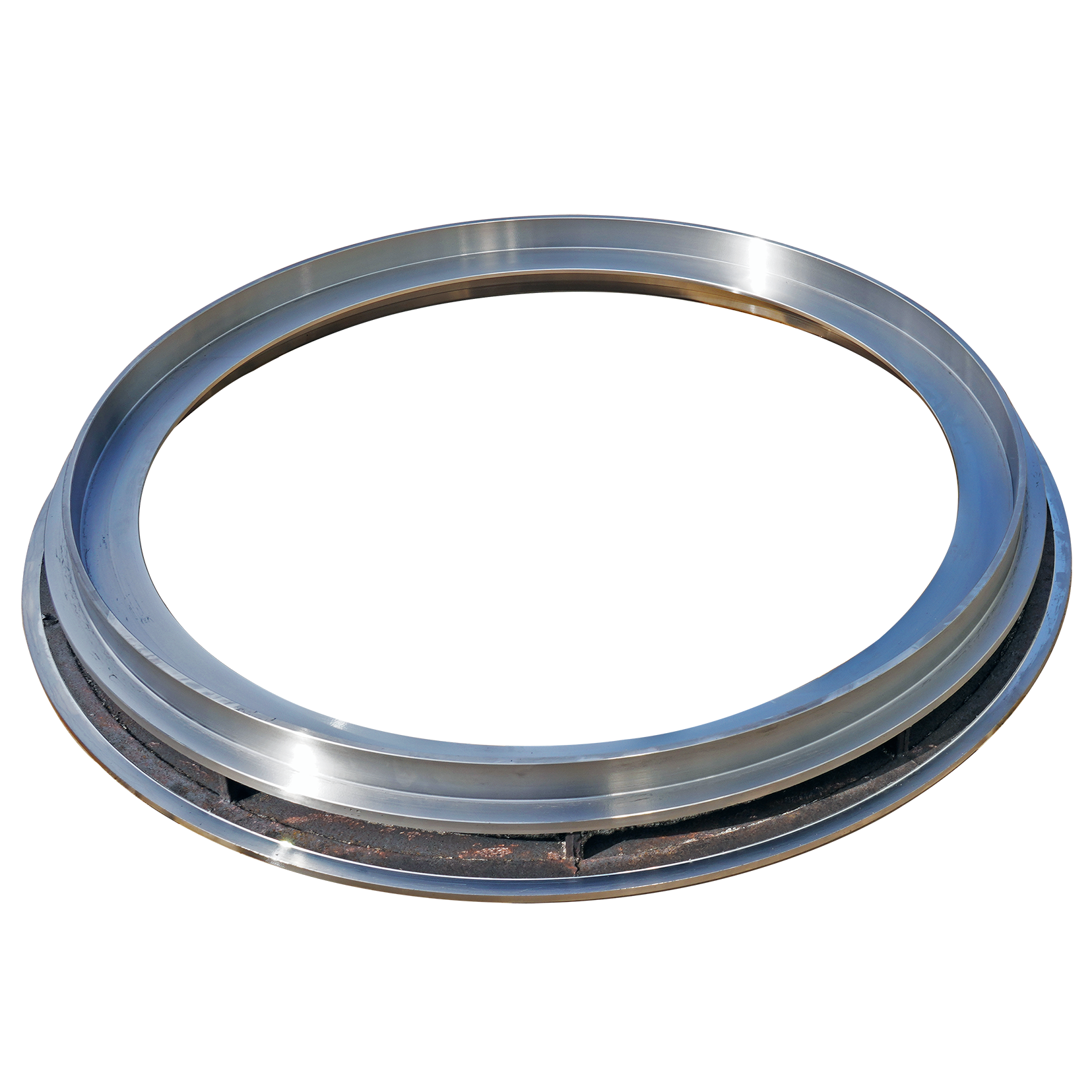

High-Quality OEM Steel Castings for Customized Industrial Solutions and Applications

OEM Steel Castings A Comprehensive Overview

In today's competitive industrial landscape, Original Equipment Manufacturers (OEMs) face the challenge of delivering high-quality products while optimizing costs and production times. One of the essential components in achieving this balance is the use of steel castings. Steel castings have become increasingly popular due to their versatility, durability, and ability to be customized to meet specific requirements. This article delves into the significance of OEM steel castings, their benefits, applications, and the considerations involved in their production.

Understanding OEM Steel Castings

OEM steel castings refer to steel components specifically manufactured for an OEM's unique requirements. These castings are produced through a process in which molten steel is poured into a mold to create parts that can withstand high stress and wear. The precision and complexity of these castings enable OEMs to produce components that fit their product specifications perfectly, enhancing performance and reliability.

Benefits of Steel Castings for OEMs

1. Customization One of the primary advantages of steel castings is their ability to be tailored to meet specific design requirements. OEMs can specify dimensions, shapes, and properties, making it easy to design components that fit seamlessly into their products.

2. Durability Steel is known for its strength and resistance to wear and corrosion. Steel castings can withstand harsh environments and heavy loads, making them ideal for use in industries such as automotive, aerospace, and heavy machinery.

3. Cost-Effectiveness While the initial investment in custom molds can be significant, OEM steel castings are often more cost-effective than other manufacturing methods for large-scale production. The efficiency of the casting process reduces labor costs and material waste, ultimately leading to lower overall production expenses.

4. Complex Geometries Steel castings can achieve complex shapes that may be difficult or impossible to create using traditional machining methods. This opens the door to innovative designs, enabling OEMs to enhance the functionality and aesthetics of their products.

5. Consistent Quality Advances in casting technology and quality control processes have significantly improved the consistency of steel castings. OEMs can rely on standardized processes to produce high-quality components repeatedly.

Applications of Steel Castings

Steel castings find applications across a wide array of industries

- Automotive Components such as engine blocks, gearboxes, and suspension parts are commonly manufactured using steel castings due to the material’s ability to handle high stresses and temperatures.

oem steel castings

- Aerospace Critical components in aircraft, including landing gear and engine mounts, often utilize steel castings to ensure safety and reliability under extreme conditions

.- Construction Heavy machinery used in construction relies on durable steel castings for parts that can withstand the rigors of demanding environments.

- Energy In the energy sector, steel castings are crucial for producing parts used in power generation equipment, including turbines and valves.

- Marine The marine industry employs steel castings for components exposed to harsh conditions, including propulsion systems, which must endure corrosion and wear.

Considerations in Manufacturing OEM Steel Castings

While the benefits of OEM steel castings are substantial, there are several considerations manufacturers must keep in mind

1. Design for Manufacturability (DFM) Collaborating with casting engineers during the design process ensures that components are optimized for casting, reducing the likelihood of defects and costly rework.

2. Material Selection Selecting the right alloy is critical, as different steel types offer varying properties. Understanding the environment in which the component will operate helps in making appropriate material choices.

3. Quality Assurance Implementing robust quality control measures throughout the casting process is essential to ensure that all specifications are met and potential defects are identified early.

4. Sustainability As industries become increasingly aware of environmental impacts, exploring sustainable practices in the production of steel castings, including recycling materials and reducing energy consumption, is important.

Conclusion

OEM steel castings represent a vital technology in modern manufacturing, providing numerous benefits in terms of customization, durability, cost-effectiveness, and complexity. As industries continue to evolve, the demand for high-quality, reliable steel castings will undoubtedly rise, driving innovation in casting techniques and materials. For OEMs, leveraging these advantages can yield significant competitive advantages and pave the way for future success in their respective markets.

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025

-

Buy Cast Iron Pipe: Premium Ductile Iron & Drain Solutions

NewsAug.07,2025

-

Durable Cast Iron Water Main Pipe | Buy Ductile Pipe

NewsAug.06,2025