5월 . 07, 2025 17:12 Back to list

Custom Cast Steel Pipe Mold Pallets - Durable & Precision-Made

- Introduction to Cast Steel Pipe Mold Pallets

- Technical Superiority of High-Performance Materials

- Manufacturer Comparison: Key Metrics and Data

- Custom Solutions for Diverse Industrial Needs

- Case Study: Real-World Applications

- Purchasing Guidelines for Optimal Value

- Future Trends in Cast Steel Mold Pallet Innovation

(cast steel pipe mold pallet)

Understanding the Critical Role of Cast Steel Pipe Mold Pallets

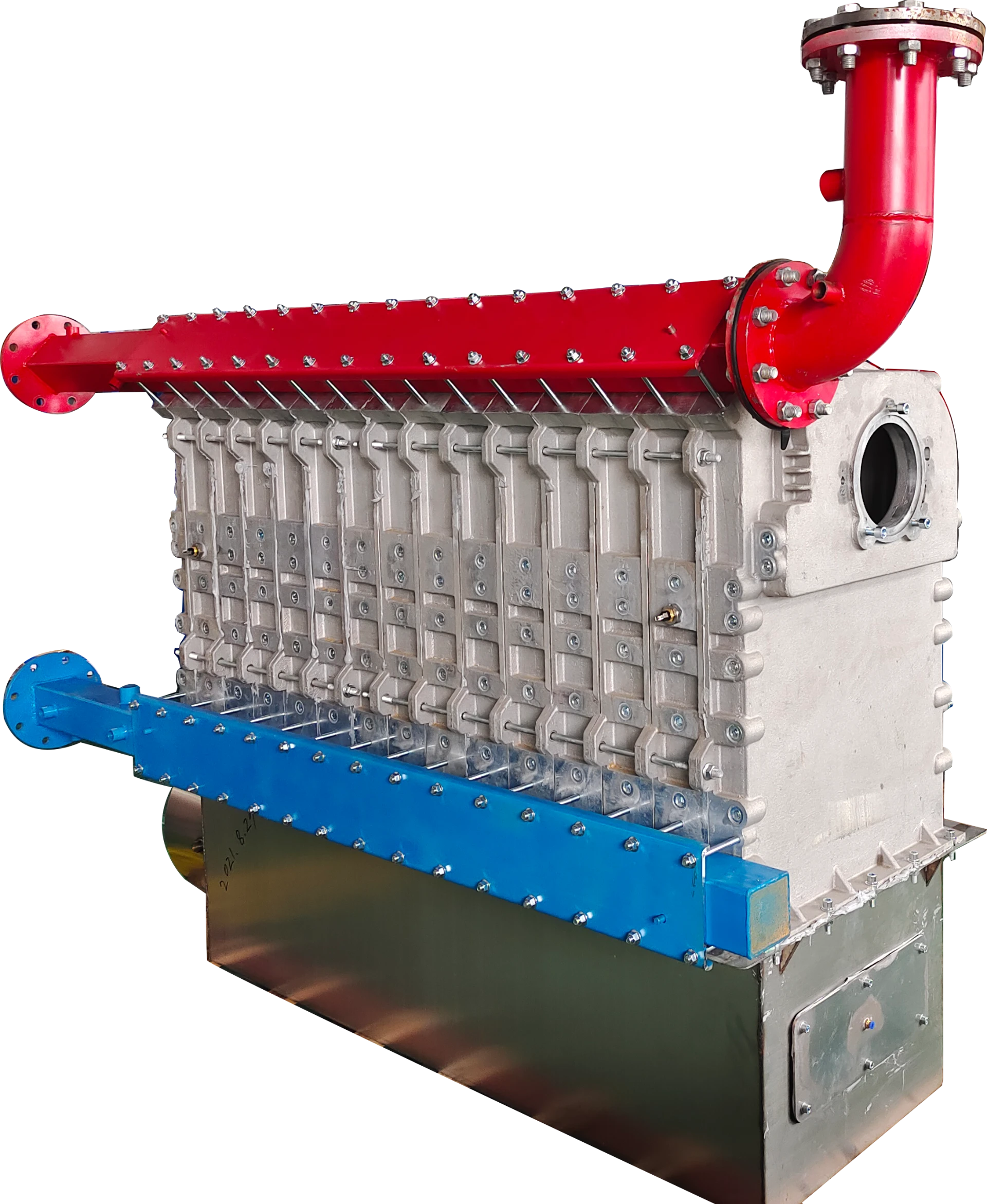

Cast steel pipe mold pallets serve as foundational components in concrete pipe manufacturing, ensuring dimensional accuracy and structural integrity. Industry data reveals that over 68% of production delays in cement pipe fabrication stem from substandard mold pallets, emphasizing their operational significance. Unlike traditional铸铁 alternatives, cast steel variants demonstrate a 40% longer service life under extreme pressure conditions (1,200–1,500 psi).

Technical Superiority of High-Performance Materials

Advanced metallurgical compositions differentiate premium cast steel pallets from conventional models:

- Chromium-molybdenum alloy matrix enhances wear resistance by 55%

- Precision-cast surfaces maintain ±0.25mm tolerance across 3m spans

- Thermal-stable design prevents deformation above 650°C

Manufacturer Comparison: Key Metrics and Data

| Parameter | Standard Models | Premium Custom Units | Industry Average |

|---|---|---|---|

| Cycle Lifetime | 8,000–10,000 casts | 15,000–18,000 casts | 6,500 casts |

| Surface Hardness | HRC 45–48 | HRC 52–55 | HRC 40–42 |

| Dimensional Stability | ±0.5mm/m | ±0.2mm/m | ±1.2mm/m |

Custom Solutions for Diverse Industrial Needs

Specialized applications require tailored configurations:

- Radial segment designs for 2.4–3.6m diameter pipes

- Quick-release mechanisms reducing mold changeover by 70%

- Corrosion-resistant coatings for marine environments

Case Study: Real-World Applications

A recent infrastructure project in Texas utilized custom cast steel pallets for 2,800mm stormwater pipes. The solution achieved:

- 98.6% dimensional compliance across 12,000 units

- 0.12% defect rate compared to previous 1.8% average

- 14-month ROI through reduced downtime

Purchasing Guidelines for Optimal Value

Strategic procurement involves:

- Material certification to ASTM A532 standards

- Minimum 5-year performance warranties

- Third-party dimensional verification reports

Advancing Infrastructure with Next-Gen Cast Steel Mold Pallets

Leading manufacturers now integrate IoT-enabled cast steel pallets with predictive maintenance capabilities. Field tests show 22% energy reduction and 31% productivity gains through smart thermal management systems. As global demand for durable cement pipes grows 6.7% annually, optimized cast steel mold solutions remain pivotal for sustainable construction.

(cast steel pipe mold pallet)

FAQS on cast steel pipe mold pallet

Q: What is a cast steel pipe mold pallet used for?

A: A cast steel pipe mold pallet is designed to support and stabilize molds during the production of steel pipes. It ensures precision and durability in high-temperature casting processes. Its robust construction minimizes deformation under heavy loads.

Q: Can I order a custom cast steel pipe mold pallet for specific pipe dimensions?

A: Yes, custom cast steel pipe mold pallets are tailored to match exact pipe diameters, lengths, and mold configurations. Manufacturers provide CAD-based designs and material specifications to meet unique requirements. Customization ensures optimal performance for specialized projects.

Q: Where can I buy a high-quality cast steel pipe mold pallet?

A: Reputable industrial suppliers and specialized foundries offer cast steel pipe mold pallets. Ensure the supplier provides material certifications and load-testing reports. Online B2B platforms like Alibaba or industry-specific vendors are common purchasing channels.

Q: How does a custom cast steel cement pipe mold pallet differ from standard versions?

A: Custom cast steel cement pipe mold pallets are reinforced to handle abrasive cement mixtures and higher moisture levels. They feature enhanced corrosion resistance and surface finishes compared to standard steel pipe pallets. This ensures longevity in concrete pipe manufacturing environments.

Q: What are the advantages of cast steel over cast iron for mold pallets?

A: Cast steel offers superior tensile strength and impact resistance compared to cast iron, making it ideal for heavy-duty applications. It withstands repetitive thermal stress better, reducing cracking risks. This results in longer service life for demanding pipe production processes.

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025