12월 . 21, 2024 09:12 Back to list

heat exchanger for low nitrogen condensing gas-fired boiler supplier

Heat Exchanger for Low Nitrogen Condensing Gas-Fired Boiler Suppliers

The demand for energy-efficient heating solutions is rising globally as governments and industries strive to reduce carbon footprints and enhance energy utilization. Among these solutions, low nitrogen condensing gas-fired boilers stand out due to their efficiency and lower emissions, making them a preferred choice in numerous applications. A key component driving the efficiency of these systems is the heat exchanger, crucial for transferring heat while minimizing nitrogen oxide (NOx) emissions. This article explores the importance of heat exchangers in these boilers and highlights key considerations for suppliers in this niche market.

Understanding Heat Exchangers

A heat exchanger is a device that facilitates the transfer of heat between two or more fluids without mixing them. In low nitrogen condensing gas-fired boilers, heat exchangers play a vital role in recovering heat from flue gases, thus improving the overall efficiency of the system. These high-efficiency boilers can achieve efficiencies of over 90% by capturing the latent heat of water vapor produced during combustion, which traditional systems often lose.

The Role of Heat Exchangers in Condensing Technology

In condensing technology, the heat exchanger is designed to operate at lower temperatures, allowing for the condensation of water vapor within the flue gases. This process not only recovers additional energy but also results in significantly lower emissions of harmful substances, particularly nitrogen oxides. The dual benefit of improved efficiency and reduced environmental impact makes these heat exchangers indispensable components in modern gas-fired boilers.

Key Supplier Considerations

1. Material Selection The choice of materials for heat exchangers is crucial, as they must withstand high temperatures and corrosive flue gases. Common materials include stainless steel and aluminum, which provide durability and resistance to corrosion. Suppliers must ensure that the materials used are suitable for the specific working conditions of the boilers they are designed for.

heat exchanger for low nitrogen condensing gas-fired boiler supplier

2. Design and Performance Optimization Suppliers should prioritize innovative designs that maximize heat transfer efficiency while minimizing pressure drops across the heat exchanger. Fin tubes and other advanced geometries can enhance the effectiveness of heat transfer. Computational fluid dynamics (CFD) simulations are valuable tools to help suppliers design effective heat exchangers.

3. Regulatory Compliance As environmental regulations tighten, it is essential for suppliers to stay informed about the latest standards related to NOx emissions and efficiency ratings. Compliance with regulations not only ensures market access but also enhances the reputation of suppliers as environmentally responsible businesses.

4. Reliability and Maintenance Suppliers must focus on the reliability of their heat exchangers. A design that minimizes fouling and is easy to clean can significantly enhance operational efficiency and extend the lifespan of the boiler. Providing clear maintenance guidelines and support can also improve customer satisfaction.

5. Customization and Innovation The ability to customize heat exchangers for specific applications can give suppliers a competitive edge. Innovations like modular designs allow for easier installation and replacement, which is particularly appealing in retrofitting existing systems.

6. Cost-Effectiveness While advanced technology and materials may increase production costs, suppliers must balance these with cost-effective solutions that do not compromise performance. Offering a range of products at different price points can cater to a broader customer base.

Conclusion

As the demand for low nitrogen condensing gas-fired boilers continues to grow, the role of heat exchangers will be paramount in ensuring efficiency and compliance with environmental standards. Suppliers of these essential components must focus on material selection, design optimization, regulatory compliance, reliability, customization, and cost-effectiveness to stay competitive in the market. By embracing innovation and sustainability, suppliers can not only contribute to a cleaner environment but also secure a robust position in the evolving energy landscape.

-

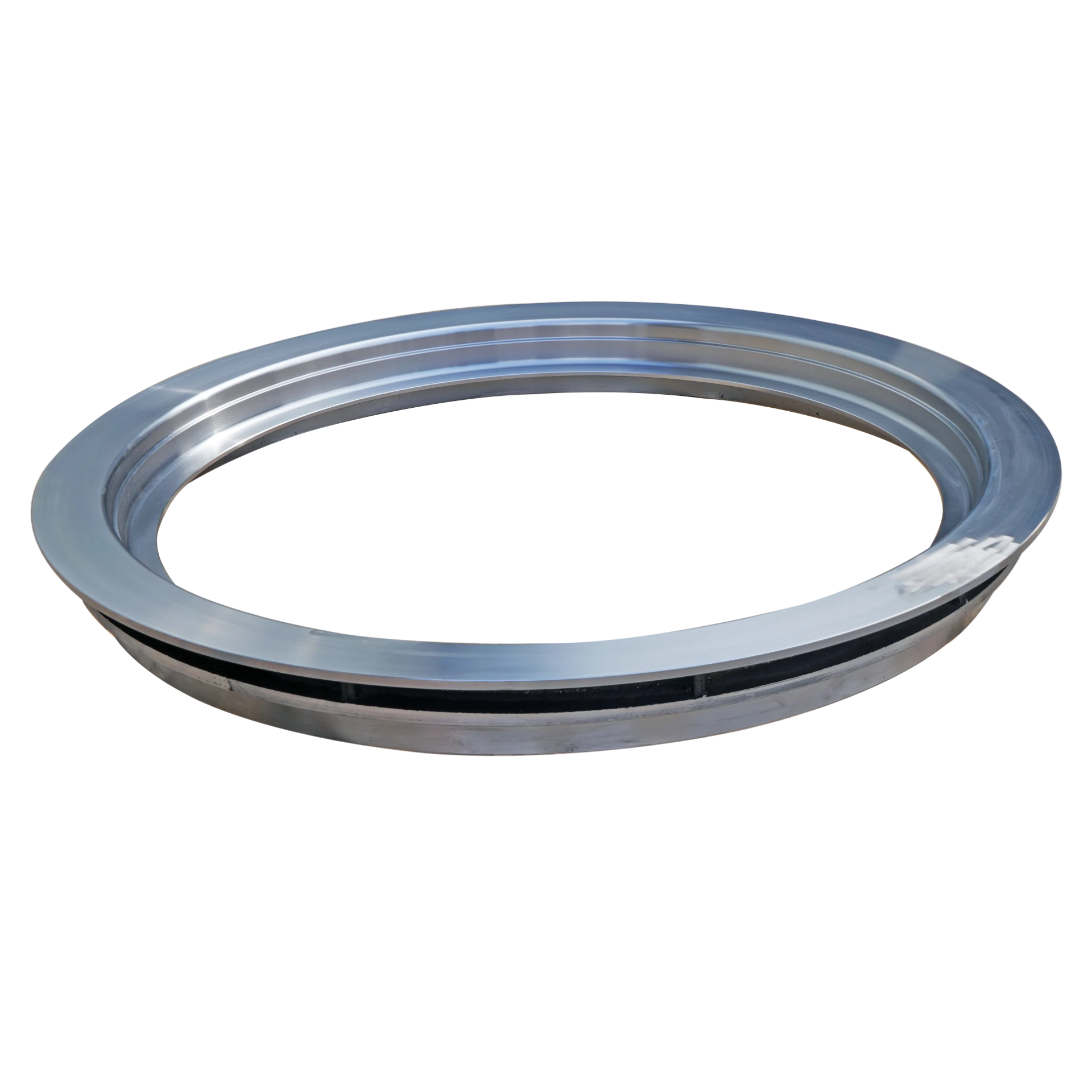

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025