تشرینی یەکەم . 15, 2024 20:06 Back to list

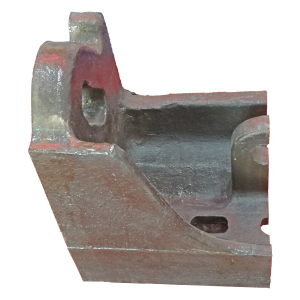

Casting Product Exporter for Quality Manufacturing Solutions and Global Supply Chain

The Significance of Casting Product Exporters in Global Trade

Casting is a manufacturing process that involves pouring molten material into a mold to form a specific shape. This process is essential for producing a wide variety of components used in various industries, including automotive, aerospace, construction, and machinery. As globalization continues to shape economic landscapes, casting product exporters play a pivotal role in facilitating international trade, driving innovation, and promoting economic growth. This article explores the significance of casting product exporters, their challenges, and the future of the industry.

Understanding Casting Products

Casting products encompass a range of items produced through the casting process, including engine blocks, turbine housings, and intricate machine parts. These products are typically made from metals such as aluminum, iron, and brass, which are chosen for their durability, corrosion resistance, and strength. The casting industry is characterized by its ability to produce complex shapes and designs that would be challenging to achieve through other manufacturing methods.

The Role of Casting Product Exporters

Casting product exporters serve as a crucial link between manufacturers and international markets. By exporting casting products, these companies enable manufacturers to access global supply chains, which is especially important in an era where production facilities are often spread around the world. This access not only helps manufacturers obtain high-quality components but also allows them to reduce costs and improve their competitiveness in the marketplace.

Moreover, casting product exporters facilitate the introduction of innovative materials and technologies to various regions, enhancing local manufacturing capabilities. By collaborating with overseas clients, these exporters can also gain insights into market trends and consumer preferences, enabling them to adapt their offerings to meet diverse customer needs.

Economic Impact

The casting industry is a significant contributor to the global economy. As a labor-intensive sector, it provides numerous job opportunities across different skill levels. Both direct and indirect employment in the casting sector can have a positive ripple effect on local economies, creating jobs in related industries such as logistics, engineering, and quality control.

casting product exporter

Furthermore, casting product exporters support the trade balance of their home countries

. By generating revenue through exports, they contribute to national income and stimulate economic growth. This economic activity can lead to increased government revenues, which can then be reinvested in public services and infrastructure.Challenges Facing Casting Product Exporters

Despite their vital role in the economy, casting product exporters face several challenges. One of the primary concerns is the fluctuating cost of raw materials. Prices for metals and other raw materials can vary significantly due to global supply and demand dynamics. These fluctuations can affect profit margins and make it difficult for exporters to maintain competitive pricing.

Additionally, exporters must navigate complex regulatory environments and compliance requirements in different countries. Adhering to industry standards and regulations can be time-consuming and costly, particularly for smaller exporters with limited resources.

Another challenge is the growing emphasis on sustainability and environmental responsibility. Consumers and governments are increasingly demanding that manufacturers adopt environmentally friendly practices. Casting product exporters must invest in sustainable production methods and technologies to meet these expectations and maintain their market position.

The Future of Casting Product Exporters

Despite the challenges, the future of casting product exporters appears promising. The rising demand for lightweight materials, especially in the automotive and aerospace industries, is driving innovation in casting technologies. Advances in additive manufacturing and 3D printing are also transforming the landscape, allowing for the production of complex geometries that were previously unattainable.

As digitalization continues to influence the manufacturing sector, casting product exporters are likely to benefit from enhanced efficiency and productivity. Industry 4.0 technologies, such as the Internet of Things (IoT) and artificial intelligence (AI), are reshaping operations, improving quality control, and enabling real-time monitoring of supply chains.

In conclusion, casting product exporters are integral to the dynamics of global trade. Their role in facilitating access to high-quality casting products is critical for various industries, driving economic growth and promoting innovation. While challenges exist, ongoing advancements and a focus on sustainability will likely ensure the continued success and relevance of this sector in the future.

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025

-

Buy Cast Iron Pipe: Premium Ductile Iron & Drain Solutions

NewsAug.07,2025