ئاب . 23, 2025 00:40 Back to list

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

Introduction to Advanced Concrete Pipe Molding Components

In the demanding landscape of modern infrastructure development, the reliability and efficiency of concrete pipe manufacturing are paramount. At the core of this process lies the mold system, where components like the base ring and pallet play a critical role in shaping the final product's integrity and dimensional accuracy. We delve into the advanced engineering and critical importance of the Cast Steel Concrete Pipe Mold Reverse Base Ring Bottom Ring Pallets Bottom Tray Base Tray, a robust solution designed to meet the rigorous demands of large-scale concrete pipe production. This composite component, often referred to interchangeably by its various functionalities as a base ring, bottom ring, pallet, bottom tray, or base tray, serves as the foundational element upon which concrete pipes are formed and cured, directly influencing their quality, consistency, and structural performance.

This comprehensive guide explores the technical intricacies, manufacturing excellence, and strategic advantages offered by high-quality cast steel components in enhancing the productivity and longevity of concrete pipe molding operations for B2B stakeholders, including plant managers, procurement specialists, and design engineers.

Industry Trends & Market Demands for Concrete Pipe Molds

The global infrastructure sector is experiencing unprecedented growth, driven by urbanization, industrial expansion, and the need for resilient water management systems. This surge necessitates higher volumes of durable concrete pipes for applications ranging from municipal water supply and drainage to industrial wastewater transport and culverts for highways. Key industry trends influencing the demand for sophisticated mold components include:

- Increased Demand for Large Diameter Pipes: Major projects often require pipes with diameters exceeding DN2000, placing immense stress on mold components and demanding superior material strength and dimensional stability.

- Emphasis on Durability and Longevity: Asset owners demand pipes with extended service lives, which begins with precise and robust molding. This translates to a need for mold components that can withstand millions of cycles without significant wear or deformation.

- Automation and High-Speed Production: Modern concrete pipe plants are increasingly automated, requiring mold components that can integrate seamlessly into high-speed production lines, ensuring rapid demolding and consistent quality.

- Sustainability and Material Efficiency: Precision molds reduce concrete wastage and minimize rejects, aligning with sustainability goals. The longevity of the mold itself also contributes to a lower environmental footprint.

- Tightening Quality Standards: International standards (e.g., ASTM, EN) are continuously evolving, demanding components that facilitate the production of pipes meeting stringent specifications for strength, impermeability, and dimensional accuracy.

These trends underscore the critical need for advanced components like the Cast Steel Concrete Pipe Mold Reverse Base Ring Bottom Ring Pallets Bottom Tray Base Tray, which are engineered for resilience, precision, and operational efficiency.

Technical Specifications & Material Excellence

The performance of a concrete pipe mold's base components hinges on meticulous technical specifications and the inherent quality of its materials. Our Cast Steel Concrete Pipe Mold Reverse Base Ring Bottom Ring Pallets Bottom Tray Base Tray products are predominantly manufactured from high-grade cast steel alloys, specifically selected for their superior mechanical properties.

Material Composition & Properties:

- Alloy Steel Grades: Typically utilizes grades such as ASTM A27 Grade 65-35, DIN EN 10293 GX20Mn5, or equivalent high-strength, wear-resistant steel. These alloys offer an excellent balance of tensile strength, yield strength, and impact resistance.

- Hardness: Post-heat treatment, components achieve a hardness range of 200-250 HB (Brinell Hardness), ensuring exceptional resistance to abrasive wear from concrete mix and repeated demolding cycles.

- Tensile Strength: Typically > 600 MPa, providing robust structural integrity under dynamic stresses during pipe formation.

- Yield Strength: > 350 MPa, preventing permanent deformation even under significant operational loads.

- Corrosion Resistance: While primary protection comes from surface coatings, the inherent alloy composition offers a degree of resistance to the alkaline environment of concrete.

Dimensional Parameters & Precision:

Precision is paramount. Components are manufactured to tight tolerances to ensure perfect concentricity and seamless integration with the outer mold and core. Typical parameters include:

- Pipe Diameter Range: Compatible with concrete pipes from DN300 up to DN3600 (or larger upon custom request).

- Dimensional Tolerance: Typically ±0.5 mm for critical mating surfaces, ensuring minimal gaps and optimal pipe formation.

- Surface Finish: Machined surfaces achieve a roughness of Ra 3.2 µm or finer, facilitating smooth demolding and preventing concrete adhesion.

- Weight: Varies significantly based on pipe diameter, ranging from several hundred kilograms for smaller pipes to several tons for large-diameter applications.

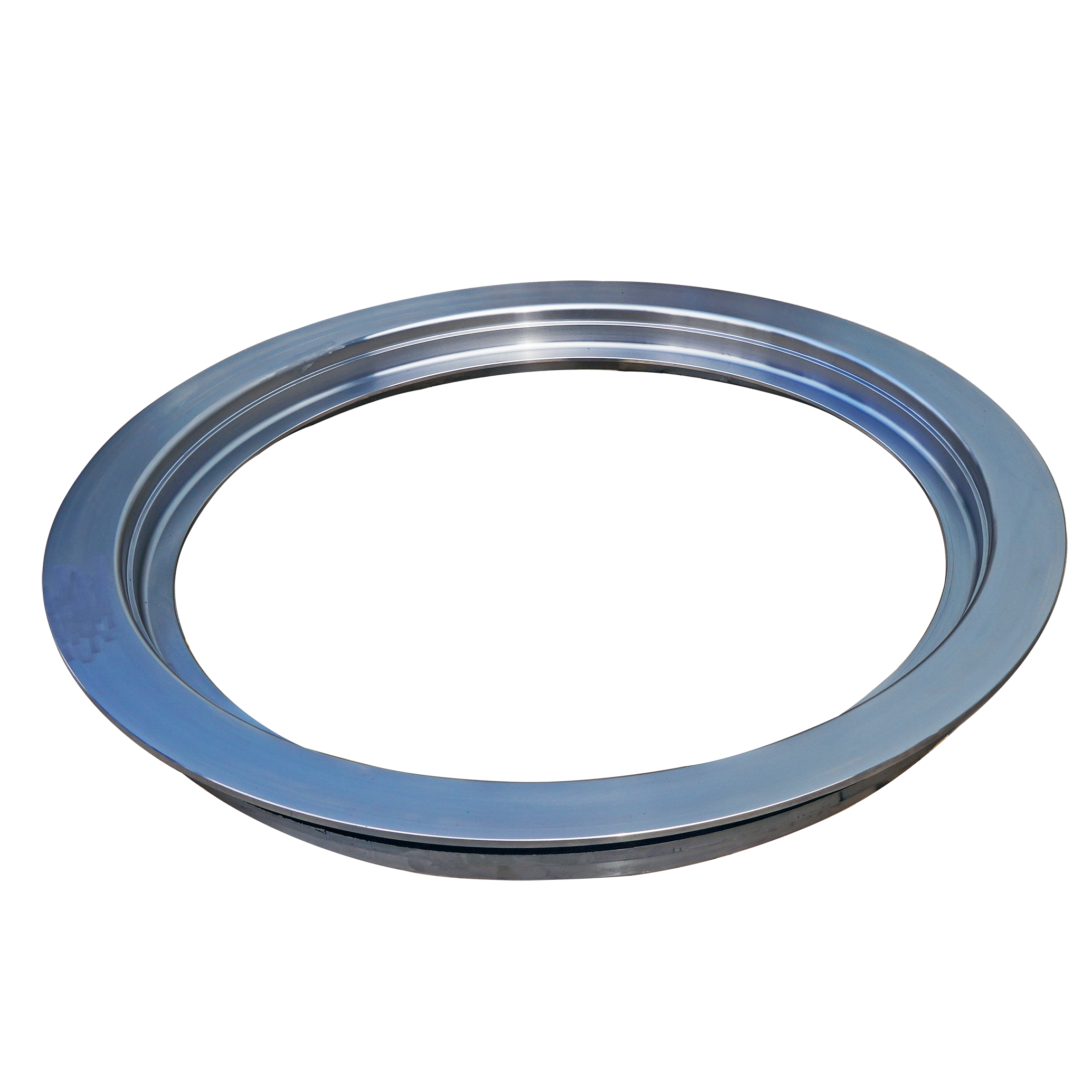

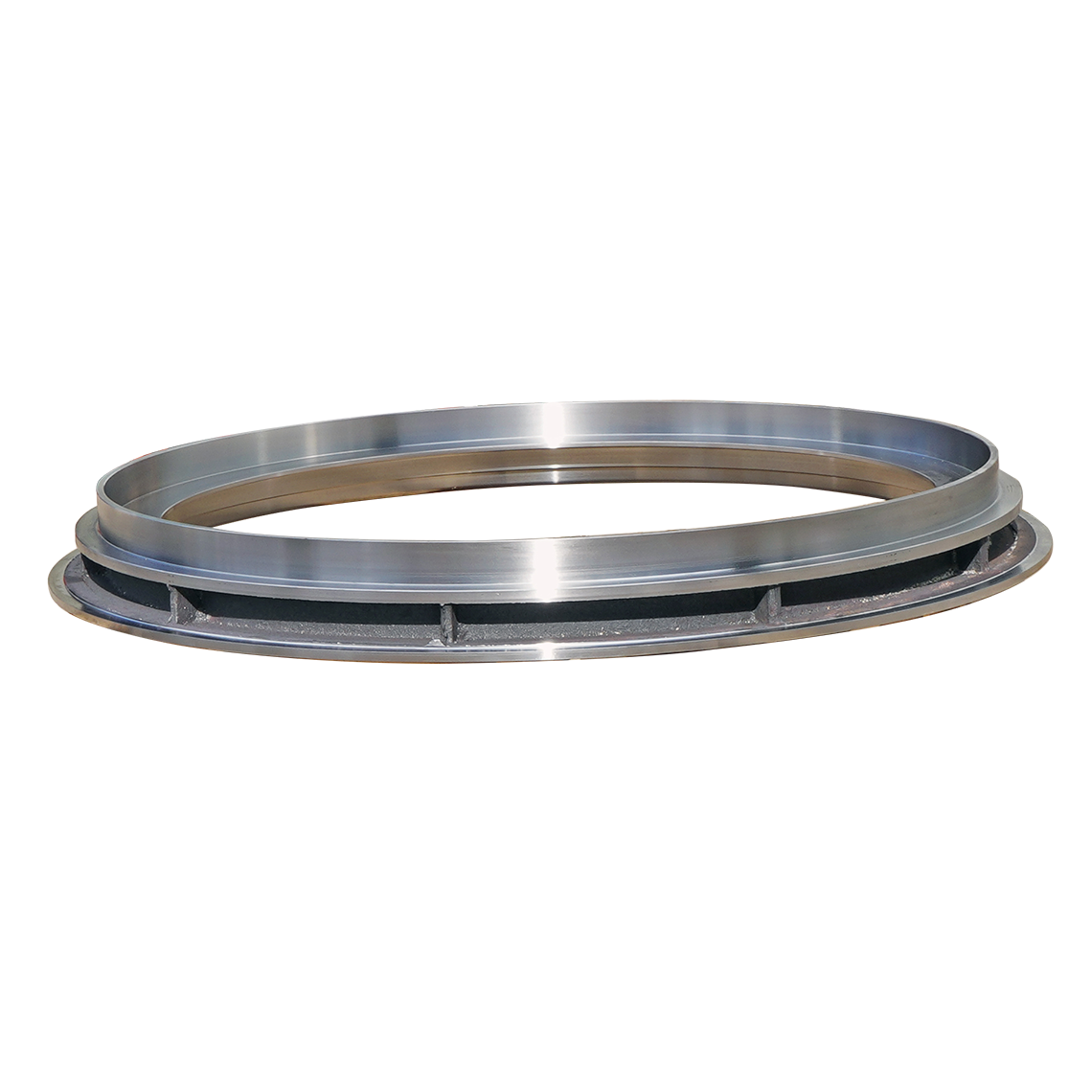

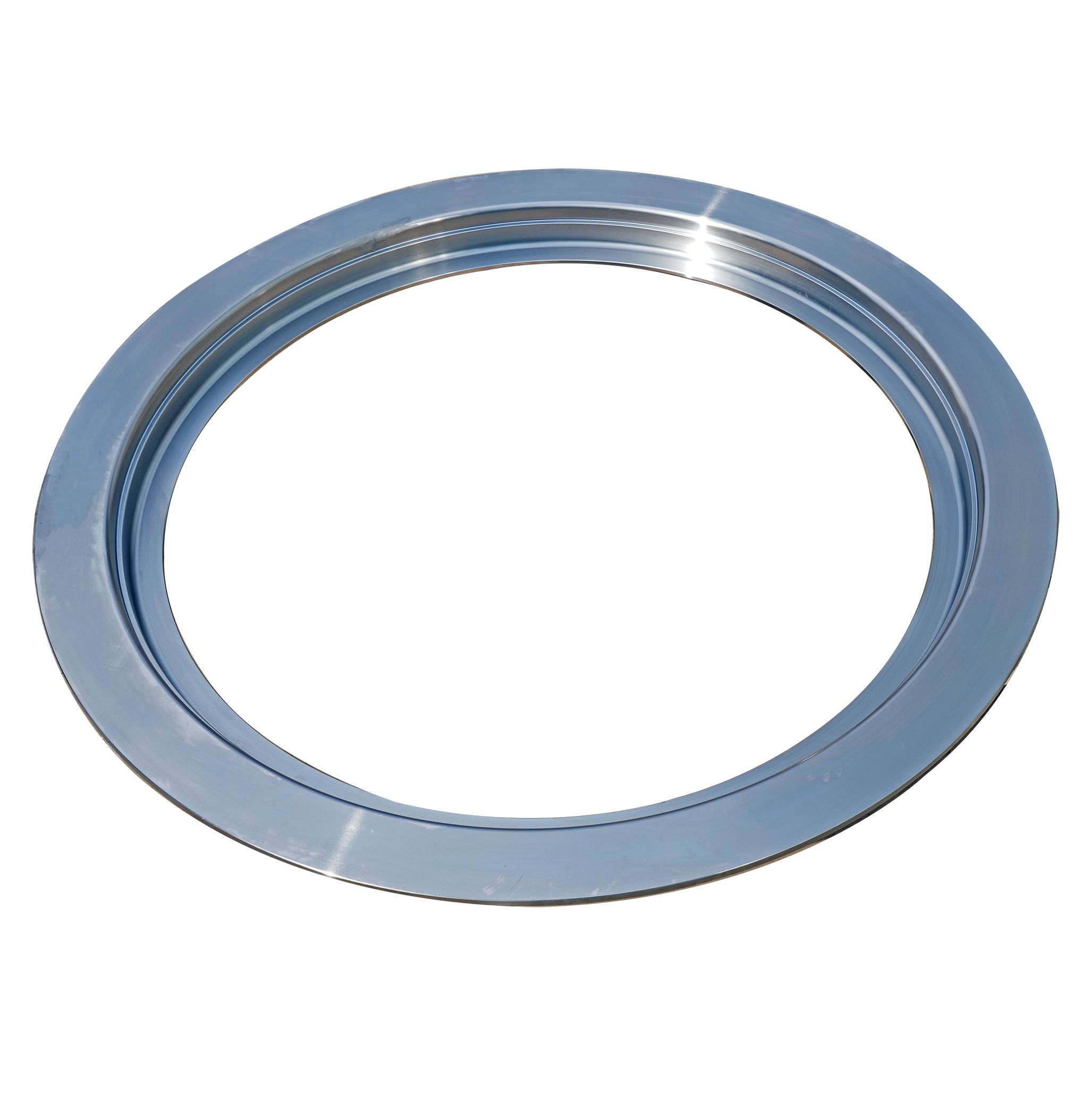

Figure 1: High-precision machined base ring for concrete pipe production.

Product Specification Table

Application Scenarios & Target Industries

The versatility and durability of the Cast Steel Concrete Pipe Mold Reverse Base Ring Bottom Ring Pallets Bottom Tray Base Tray make it indispensable across a spectrum of industries that rely on robust underground or surface piping infrastructure. These components are critical for manufacturers producing various types of concrete pipes, including:

- Water Supply & Drainage (WSD): Essential for stormwater runoff, sewage systems, and potable water conveyance, where pipe integrity and long-term performance are crucial.

- Irrigation Systems: Used in large-scale agricultural projects requiring efficient and durable water distribution networks.

- Culverts for Roadways & Railways: Providing structural support and water flow management beneath critical transportation infrastructure.

- Industrial Pipelines: For non-corrosive industrial wastewater, process water, or other fluid transport within large manufacturing or processing facilities.

- Hydroelectric Projects: Forming integral parts of penstocks and other large-diameter conduits for water management.

Figure 2: Concrete pipe production line showcasing the role of base components.

In these scenarios, the base rings and pallets ensure the production of pipes with consistent wall thickness, high compressive strength, and minimal imperfections, which translates directly to reduced project risks, extended service life of infrastructure, and compliance with strict engineering standards. The ability to produce uniform pipes reliably and efficiently is a direct consequence of the quality of the molding components used.

Technical Advantages of Cast Steel Components

Opting for cast steel in the manufacturing of the Cast Steel Concrete Pipe Mold Reverse Base Ring Bottom Ring Pallets Bottom Tray Base Tray offers a multitude of technical and operational advantages over alternative materials or manufacturing methods, significantly impacting the total cost of ownership (TCO) and overall production efficiency.

- Superior Strength and Durability: Cast steel exhibits higher tensile strength, yield strength, and impact resistance compared to ductile iron or fabricated mild steel. This translates to a longer service life, significantly reducing replacement frequency and associated downtime.

- Exceptional Wear Resistance: The metallurgical properties of specific cast steel alloys, often enhanced by precise heat treatments, provide excellent resistance to the abrasive forces of concrete and the repeated stresses of vibratory compaction and demolding.

- High Dimensional Stability: Cast steel, post-machining, retains its precise dimensions even after prolonged use under heavy loads and temperature fluctuations. This ensures consistent pipe geometry, minimizing defects and improving overall product quality.

- Optimized Design Flexibility: The casting process allows for complex geometries and integrated features that might be difficult or costly to achieve with fabrication. This enables optimized designs for improved concrete flow, vibration transfer, and demolding efficiency.

- Reduced Maintenance and Downtime: The robust nature of cast steel components means fewer failures, less frequent maintenance, and extended operational periods, directly contributing to higher plant throughput and lower operational costs.

- Enhanced Vibration Transfer: The monolithic structure and high density of cast steel provide superior vibration transmission from vibrators to the concrete mix, aiding in better compaction and air void removal, leading to denser, stronger pipes.

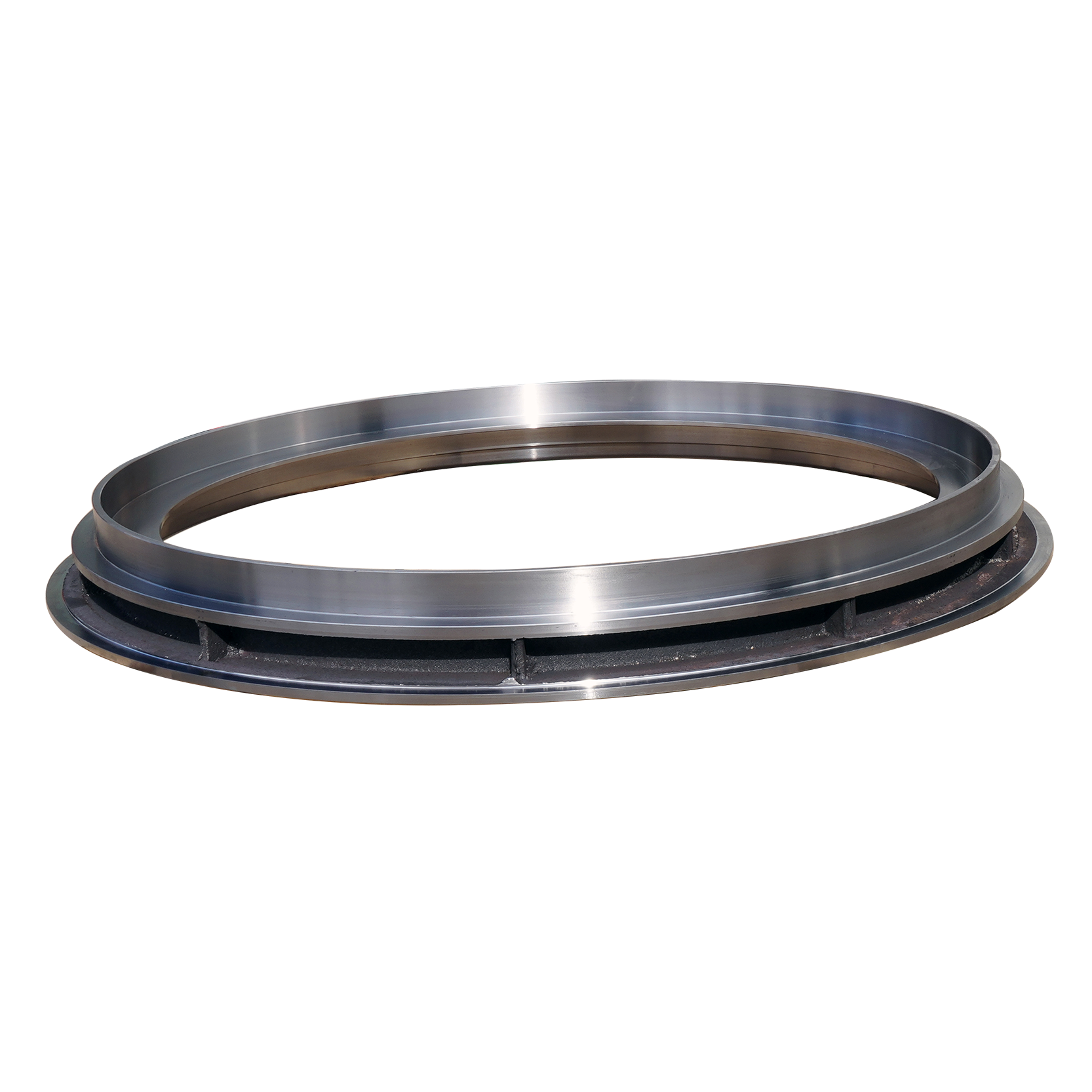

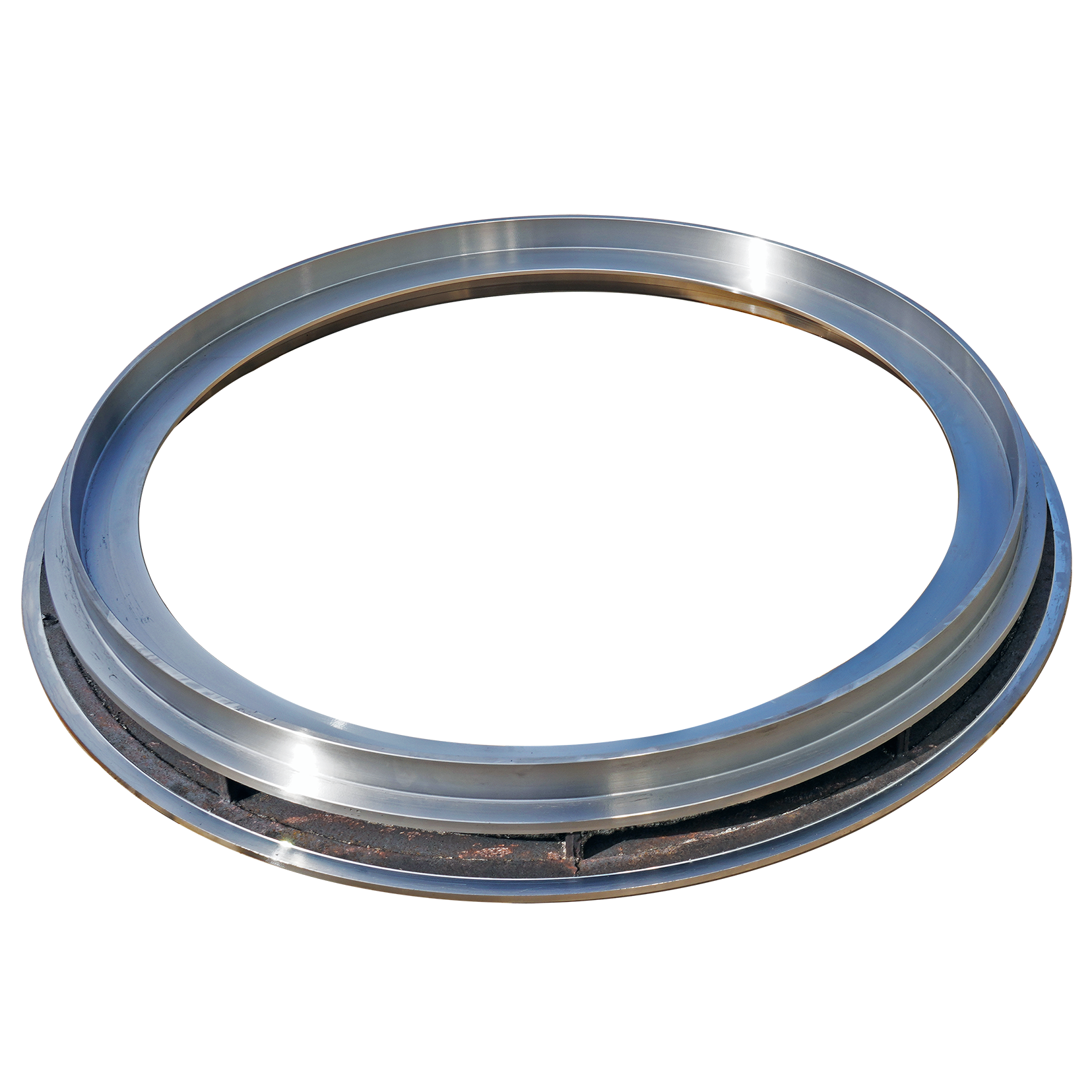

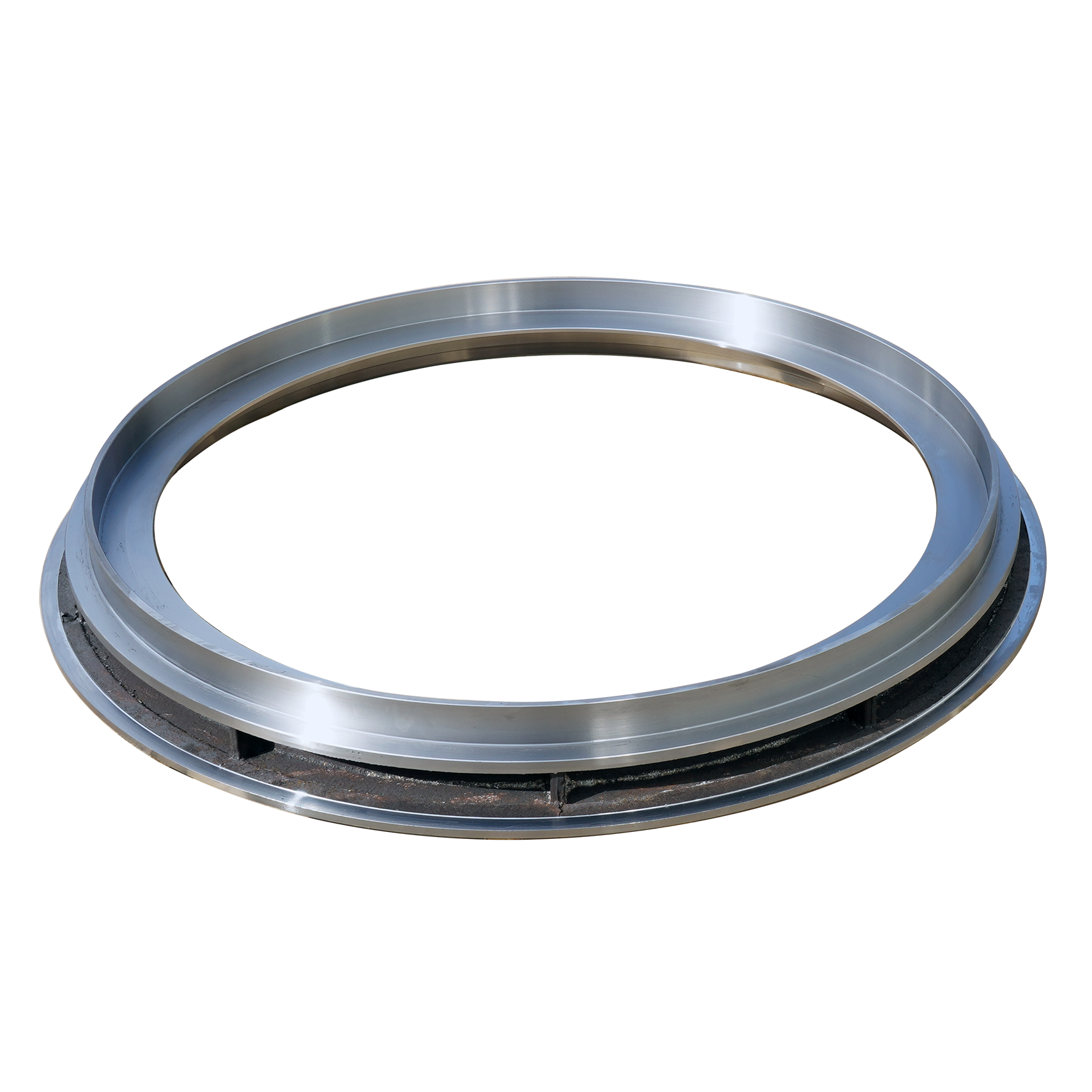

Figure 3: Close-up of a base ring demonstrating surface finish and structural integrity.

These advantages collectively translate into a compelling return on investment for concrete pipe manufacturers, solidifying cast steel as the material of choice for critical mold components.

Manufacturing Process Flow for Cast Steel Pipe Mold Components

The production of a high-quality Cast Steel Concrete Pipe Mold Reverse Base Ring Bottom Ring Pallets Bottom Tray Base Tray involves a sophisticated multi-stage process, blending advanced metallurgy with precision engineering. Each step is meticulously controlled to ensure the final product meets stringent quality and performance criteria.

- Design & Engineering (CAD/CAM/FEA):

Utilizing advanced CAD software, designs are optimized for specific pipe diameters, production methods (e.g., vertical vibration, roller suspension), and customer requirements. Finite Element Analysis (FEA) simulates stress distribution and operational loads to predict performance and refine structural integrity, ensuring optimal material distribution and fatigue resistance.

- Pattern Making:

Based on CAD models, precision patterns (made from wood, resin, or foam) are created. These patterns are slightly oversized to account for material shrinkage during solidification.

- Molding & Core Making:

Sand molding (e.g., furan resin sand or green sand) is commonly used. The pattern is used to create a cavity in the sand mold. Cores are produced separately for internal features or hollow sections.

- Melting & Pouring:

High-frequency induction furnaces or electric arc furnaces melt the selected steel alloy. Strict control over chemical composition is maintained through spectrometry. Molten steel, at specific temperatures (e.g., 1550-1650°C), is carefully poured into the prepared sand molds, often utilizing bottom-pouring techniques to minimize turbulence and inclusions.

- Solidification & Shakeout:

After pouring, the molten steel solidifies. Once cooled sufficiently, the casting is removed from the sand mold (shakeout). Risers and gates (feeding channels) are then removed.

- Fettling & Heat Treatment:

Fettling involves cleaning the raw casting, removing any residual sand, and grinding away rough edges or excess material. This is followed by critical heat treatment processes, such as normalizing (to refine grain structure and reduce internal stresses) or quenching and tempering (to achieve specific hardness and strength profiles, optimizing wear resistance and toughness).

- Rough Machining & Stress Relieving:

Initial machining operations remove excess material, preparing the casting for precision work. An intermediate stress-relieving heat treatment may be performed to eliminate stresses induced by rough machining before final precision steps.

- CNC Precision Machining:

Utilizing advanced multi-axis CNC machining centers, critical dimensions, concentricity, flatness, and surface finishes are achieved with sub-millimeter precision. This stage is crucial for ensuring the base ring interfaces perfectly with other mold components and produces dimensionally accurate pipes.

- Quality Control & Non-Destructive Testing (NDT):

Each component undergoes rigorous inspection. This includes dimensional verification using CMM (Coordinate Measuring Machine), hardness testing (Brinell, Rockwell), surface finish checks, and NDT methods such as Ultrasonic Testing (UT) for internal defects, Magnetic Particle Inspection (MPI) for surface cracks, and visual inspection. Compliance with ISO 9001 and specific material standards (e.g., ASTM, ANSI) is strictly adhered to.

- Surface Treatment & Protection:

Components may receive anti-corrosion coatings, primers, or specialized surface treatments to enhance longevity and resistance to the harsh working environment.

- Final Assembly & Packaging:

Components are assembled if required and carefully packaged to prevent damage during transit, ready for global shipment.

Figure 4: A casting being prepared for further processing, highlighting the raw material stage.

Vendor Comparison & Strategic Selection

Choosing the right supplier for Cast Steel Concrete Pipe Mold Reverse Base Ring Bottom Ring Pallets Bottom Tray Base Tray is a strategic decision that impacts production quality, operational costs, and long-term reliability. A robust vendor comparison considers more than just initial price. Key differentiators include:

Key Comparison Factors:

- Material Quality & Metallurgy Expertise: Does the vendor have in-house metallurgical expertise and control over their casting process to ensure consistent material properties?

- Manufacturing Precision & Technology: What is their investment in CNC machining, heat treatment, and quality control equipment? Do they adhere to international standards like ISO 9001?

- Customization Capabilities: Can they adapt designs for unique pipe specifications, different production methods, or specific client needs?

- Experience & Track Record: Years in the industry, number of molds supplied, and reputable client base.

- Lead Time & Logistics: Ability to meet production schedules and manage complex international shipping.

- After-Sales Support & Warranty: Availability of technical support, spare parts, and comprehensive warranty terms.

- Certifications: Compliance with international quality (e.g., ISO 9001) and material standards.

Vendor Comparison Table (Illustrative):

Figure 5: Different sizes of base rings awaiting shipment.

Customized Solutions for Unique Requirements

Understanding that concrete pipe manufacturing is rarely a one-size-fits-all operation, leading suppliers offer extensive customization capabilities for the Cast Steel Concrete Pipe Mold Reverse Base Ring Bottom Ring Pallets Bottom Tray Base Tray. This bespoke approach ensures optimal performance, seamless integration, and maximum efficiency for specific plant configurations and pipe specifications.

- Tailored Dimensions: Components can be custom-engineered to precise internal and external diameters, heights, and flange configurations to match existing molds, pipe designs, or specific machine requirements.

- Material Grade Optimization: While standard cast steel grades are robust, specific applications (e.g., extremely high vibration, highly abrasive aggregates) may benefit from custom alloy compositions or advanced heat treatments to further enhance wear resistance, toughness, or fatigue life.

- Design Modifications: Custom features such as specific lifting points, integrated sensors, unique demolding angles, or modifications for specialized pipe types (e.g., jacking pipes, box culverts) can be incorporated.

- Surface Enhancements: Application of specialized coatings or surface treatments (e.g., nitriding, hard chroming) to further reduce friction, improve corrosion resistance, or extend service life in challenging environments.

- Engineering Consultation: A collaborative process where expert engineers work with clients to analyze their existing setup, production goals, and challenges to design a base ring solution that delivers superior performance and value.

This ability to provide tailored solutions ensures that investments in mold components are optimized for maximum return and operational advantage.

Application Case Studies & Performance Metrics

Real-world application demonstrates the tangible benefits of utilizing high-quality Cast Steel Concrete Pipe Mold Reverse Base Ring Bottom Ring Pallets Bottom Tray Base Tray components. These case studies highlight improved operational efficiency, reduced costs, and enhanced product quality.

Case Study 1: Municipal Drainage Project, Southeast Asia

- Challenge: A large concrete pipe manufacturer faced frequent replacements of ductile iron base rings (every 200,000 cycles) due to excessive wear and deformation, leading to production bottlenecks and inconsistent pipe dimensions for DN1800 stormwater pipes.

- Solution: Implemented cast steel base rings with enhanced heat treatment.

- Results:

- Increased Service Life: Average lifespan extended to over 800,000 cycles, a 300% improvement.

- Reduced Downtime: Mold changeovers decreased by 75%, significantly boosting annual production capacity.

- Improved Pipe Quality: Dimensional accuracy improved by 15%, resulting in fewer rejects and higher client satisfaction.

Case Study 2: Highway Culvert System, North America

- Challenge: A pipe plant producing large-diameter (DN2400-DN3000) culvert pipes experienced issues with base tray stability under extreme vibratory compaction, leading to subtle ovality and cracking in the finished pipes.

- Solution: Custom-designed cast steel bottom trays with optimized structural reinforcement and a higher yield strength steel alloy.

- Results:

- Eliminated Ovality: Consistent pipe geometry achieved, meeting stringent highway construction standards.

- Enhanced Durability: No reported structural failures or significant wear after 600,000 cycles, demonstrating superior fatigue resistance.

- Cost Savings: Avoided costly re-manufacturing and on-site pipe rejections.

Figure 6: A completed concrete pipe segment showcasing the precision achieved by quality molds.

Frequently Asked Questions (FAQ)

Q1: Why choose cast steel over ductile iron for concrete pipe mold components?

A1: Cast steel generally offers higher tensile strength, yield strength, and superior wear resistance compared to ductile iron. This translates to significantly longer service life, less deformation under stress, and better resistance to abrasive wear from concrete, especially in high-volume or large-diameter pipe production. While ductile iron can be cost-effective initially, cast steel often provides a lower total cost of ownership due to reduced replacements and downtime.

Q2: What is the typical service life of a Cast Steel Concrete Pipe Mold Reverse Base Ring Bottom Ring Pallets Bottom Tray Base Tray?

A2: The service life can vary based on factors like concrete mix abrasiveness, operational intensity, and maintenance. However, high-quality cast steel components, properly heat-treated and maintained, are designed to last for 500,000 to over 1,000,000 production cycles. This is a substantial improvement over other materials.

Q3: Can these components be customized for specific pipe sizes or machine types?

A3: Absolutely. Leading manufacturers offer extensive customization. This includes tailoring dimensions (diameter, height, flange design), optimizing material grades for specific demands, and incorporating unique features to ensure perfect compatibility with your existing concrete pipe machines and the types of pipes you produce.

Q4: What quality control measures are in place during manufacturing?

A4: Reputable manufacturers adhere to strict quality protocols, including ISO 9001 certification. Key measures encompass chemical analysis of raw materials, rigorous heat treatment control, dimensional inspection with CMM, hardness testing, and Non-Destructive Testing (NDT) such as Ultrasonic Testing (UT) and Magnetic Particle Inspection (MPI) to detect any internal or surface flaws.

Lead Time, Warranty & Customer Support

Lead Time & Fulfillment:

Standard Cast Steel Concrete Pipe Mold Reverse Base Ring Bottom Ring Pallets Bottom Tray Base Tray components typically have a lead time of 6-10 weeks, depending on material availability, current production schedules, and the complexity of the order. Custom-engineered solutions may require an extended lead time, usually between 10-16 weeks, to accommodate design, pattern making, and specialized manufacturing processes. We work closely with clients to establish realistic timelines and provide real-time updates on order status.

Warranty Commitments:

Our products come with a comprehensive warranty against manufacturing defects and material failures under normal operating conditions. A standard warranty period of 12-24 months from the date of delivery is provided, covering structural integrity and dimensional accuracy. Specific warranty terms will be detailed in the quotation and purchase agreement.

Customer Support & After-Sales Service:

We are committed to long-term client success. Our dedicated after-sales support includes:

- Technical Assistance: Expert engineers available for troubleshooting, operational guidance, and optimization advice.

- Spare Parts Supply: Efficient supply chain for any necessary replacement components to minimize downtime.

- On-Site Support: For critical issues or complex installations, on-site technical assistance can be arranged globally.

- Maintenance Guidance: Providing best practices for prolonging the life and performance of your mold components.

Figure 7: Securely packaged base rings, ready for global distribution.

Conclusion

The selection of high-quality components for concrete pipe molds is a foundational decision impacting every aspect of production, from efficiency and cost to the ultimate quality and longevity of the finished pipes. The Cast Steel Concrete Pipe Mold Reverse Base Ring Bottom Ring Pallets Bottom Tray Base Tray stands as a testament to engineering excellence, offering unmatched durability, precision, and operational advantages. By investing in these advanced cast steel components, concrete pipe manufacturers can significantly enhance their competitive edge, reduce long-term operational costs, and consistently deliver superior products that meet the evolving demands of modern infrastructure. Prioritizing material science, manufacturing precision, and dedicated customer support ensures a reliable partnership in building the future's essential infrastructure.

References

- ASTM International. "A27/A27M, Standard Specification for Steel Castings, Carbon, for General Application." www.astm.org.

- European Committee for Standardization. "DIN EN 10293, Steel castings for general engineering uses." www.cen.eu.

- International Organization for Standardization. "ISO 9001: Quality management systems – Requirements." www.iso.org.

- Portland Cement Association. "Concrete Pipe Design and Installation." www.cement.org.

- American Concrete Pipe Association. "Concrete Pipe Handbook." www.concretepipe.org.

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025