Gru . 16, 2024 18:31 Back to list

Custom Cast Silicon Aluminum Alloy Heat Exchanger for Enhanced Thermal Efficiency and Performance

Custom Cast Silicon Aluminum Alloy Heat Exchangers An Innovative Approach for Enhanced Thermal Management

In the realm of thermal management, heat exchangers play a crucial role in ensuring efficient heat transfer between two or more fluids at different temperatures. As industries evolve and the demand for effective thermal systems increases, the need for innovative materials and designs has intensified. One such innovation is the custom cast silicon aluminum alloy heat exchanger, which not only enhances thermodynamic efficiency but also provides numerous advantages over conventional materials.

Understanding Silicon Aluminum Alloys

Silicon aluminum alloys, commonly used in a wide range of engineering applications, are known for their exceptional resistance to corrosion, thermal stability, and strength. The incorporation of silicon into the aluminum matrix improves casting properties, making it easier to produce complex shapes and intricate designs. This ability to be custom cast allows manufacturers to tailor the heat exchangers to specific applications, thereby optimizing performance for a variety of thermal management scenarios.

Advantages of Custom Cast Heat Exchangers

One of the primary benefits of utilizing custom cast silicon aluminum alloys for heat exchangers is the improved thermal conductivity they provide. The unique composition of these alloys allows for superior heat transfer compared to traditional aluminum or copper heat exchangers. This means that systems designed with silicon aluminum alloys can achieve better cooling or heating efficiencies, ultimately reducing energy consumption and operating costs.

Moreover, custom casting techniques allow for more intricate designs that maximize surface area without increasing the volume of the heat exchanger. This leads to enhanced heat transfer rates and better overall efficiency. Specialized shapes can improve fluid flow dynamics, reducing the risk of hot spots and improving the lifespan of the device.

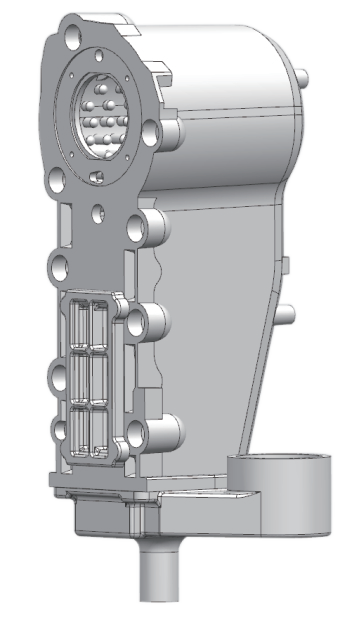

custom cast silicon aluminum alloy heat exchanger

Applications Across Industries

The application spectrum for custom cast silicon aluminum alloy heat exchangers is vast. In the automotive sector, these materials are increasingly employed in engine cooling systems, air conditioning units, and hybrids. Given their lightweight yet durable characteristics, they contribute to reduced vehicle weight, improving fuel efficiency without compromising thermal management functionality.

In the aerospace industry, where reliability and performance are paramount, custom cast heat exchangers made from silicon aluminum alloys offer enhanced thermal stability and reduced susceptibility to fatigue. These properties are crucial for maintaining optimal performance in extreme conditions.

Additionally, the industrial sector benefits from these advanced heat exchangers by implementing them into manufacturing processes that require efficient cooling, such as plastics processing and chemical production. The corrosion resistance of silicon aluminum alloys ensures longevity in harsh environments, translating to lower maintenance and replacement costs.

The Future of Thermal Management

As industries continue to prioritize sustainability and efficiency, the development and use of custom cast silicon aluminum alloy heat exchangers are likely to expand. Ongoing research into alloy compositions and casting techniques will further enhance their performance. Additionally, advancements in design software and 3D printing technologies may enable even more complex heat exchanger designs, pushing the boundaries of what is possible in thermal management solutions.

Ultimately, custom cast silicon aluminum alloy heat exchangers represent a significant advancement in thermal management technologies. Their enhanced thermal properties, tailored designs, and broad applicability make them an attractive choice for a range of industries. As demand for energy-efficient solutions grows, these heat exchangers will undoubtedly play a pivotal role in shaping the future of thermal systems, meeting both current and future thermodynamic challenges. Companies that leverage this technology will not only realize improved performance but also contribute to a more sustainable industrial landscape.

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025

-

Buy Cast Iron Pipe: Premium Ductile Iron & Drain Solutions

NewsAug.07,2025