Lap . 27, 2024 08:51 Back to list

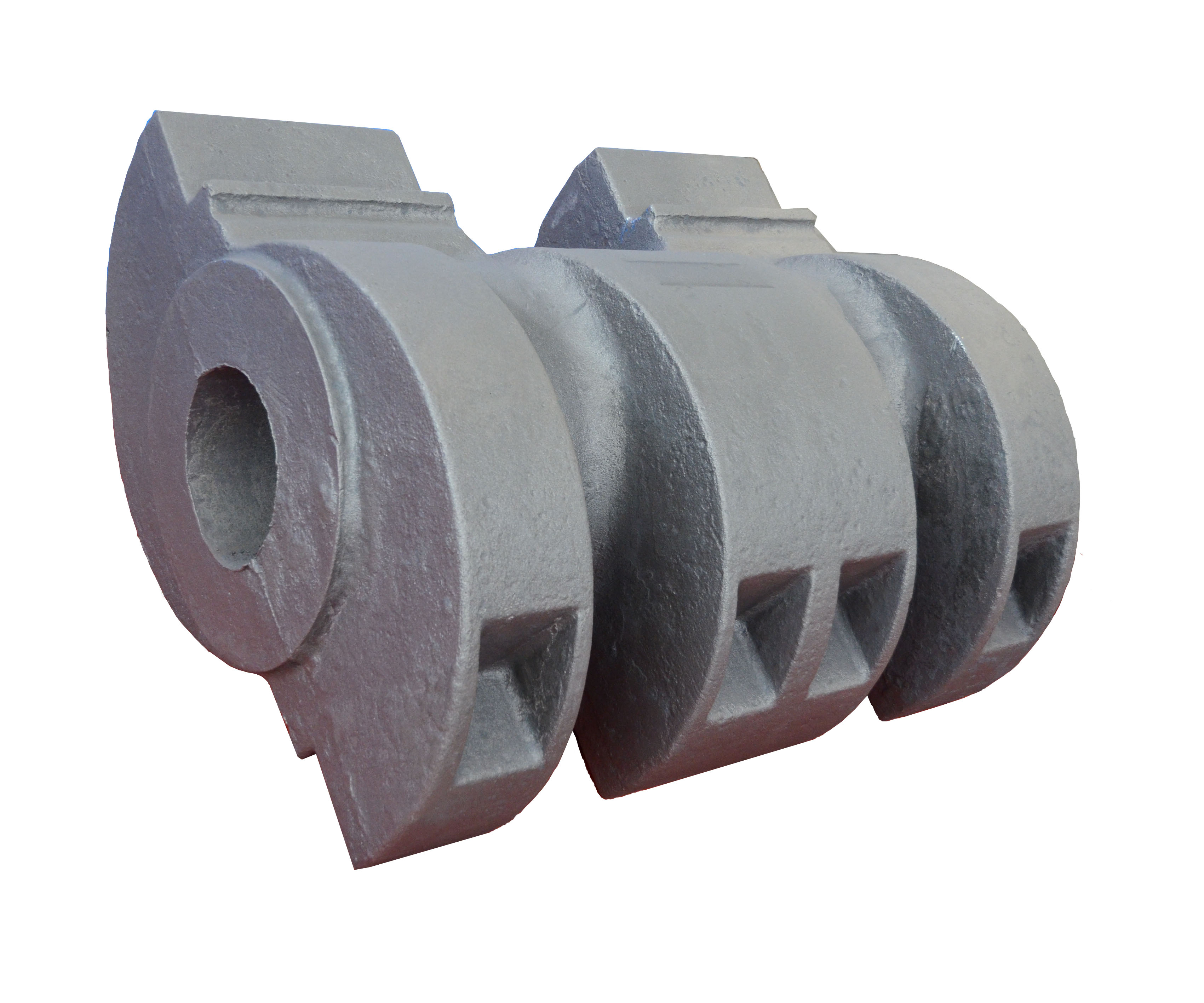

Premium Quality Casting Solutions from China for Diverse Industries and Applications

High Quality China Casting An Industry Overview

In recent years, China has cemented its position as a global leader in the casting industry. The term casting refers to a manufacturing process where liquid material is poured into a mold to achieve a desired shape upon solidification. This process is crucial for producing a wide range of metal components that serve various industries, including automotive, aerospace, construction, and machinery. High-quality casting from China is recognized for its precision, durability, and cost-effectiveness, making it an attractive option for global clients.

Advanced Technology and Techniques

One of the primary factors contributing to the high quality of Chinese castings is the continuous investment in advanced technology and manufacturing techniques. Chinese foundries have embraced modern technologies such as computer-aided design (CAD), computer-aided manufacturing (CAM), and rapid prototyping. These technologies allow for greater accuracy in the design phase and streamline the production process, leading to higher quality end products.

Additionally, Chinese manufacturers have adopted various casting methods, including sand casting, investment casting, die casting, and lost foam casting. Each method has its advantages and is chosen based on the specific requirements of the products being manufactured. For instance, investment casting is renowned for its ability to produce intricate shapes with excellent surface finishes and tighter tolerances, making it ideal for complex components used in the aerospace sector.

Strict Quality Control Standards

Quality assurance is paramount in the Chinese casting industry. Many foundries implement rigorous quality control measures throughout the production process. From the selection of raw materials to final product inspections, each step is closely monitored to ensure that the resulting castings meet or exceed international quality standards.

High Quality China Casting An Industry Overview

Furthermore, advanced testing methods, such as non-destructive testing (NDT), metallurgical analysis, and dimensional inspections, are routinely employed to identify any defects before the products are shipped. This diligent quality control not only boosts the reliability of the products but also enhances customer satisfaction.

high quality china casting

Cost-Effectiveness and Efficiency

Another significant advantage of procuring castings from China is the cost-effectiveness of the manufacturing process. Labor costs in China, while rising, are still competitive compared to many Western countries. Additionally, economies of scale in production allow for lower per-unit costs, making it an attractive option for businesses looking to optimize their manufacturing expenditures.

Moreover, the supply chain in China is well-developed, which helps ensure timely delivery of raw materials and finished products. This efficiency is crucial in today’s fast-paced market, where delays can result in lost revenue and competitiveness.

Global Reach and Partnerships

Chinese casting manufacturers have successfully established partnerships and supply chain relations with companies worldwide. They cater to diverse markets, including Europe, North America, and Asia-Pacific, allowing them to adapt their offerings to various regional standards and customer preferences.

The global demand for high-quality castings continues to rise, driven by advancements in technology and the need for durable, reliable components across various industries. As a result, the Chinese casting industry is poised to meet this demand while continuously evolving to maintain its leadership position.

Conclusion

In conclusion, the high-quality casting produced in China stands out due to its advanced technologies, strict quality control standards, and cost-effectiveness. As industries around the world continue to rely on precision-engineered components, Chinese manufacturers are well-positioned not only to meet these needs but also to innovate and adapt to the ever-changing landscape of global manufacturing. With an unwavering commitment to quality and efficiency, China remains at the forefront of the casting industry, providing essential components that power various sectors worldwide.

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025

-

Buy Cast Iron Pipe: Premium Ductile Iron & Drain Solutions

NewsAug.07,2025