Lap . 05, 2024 04:12 Back to list

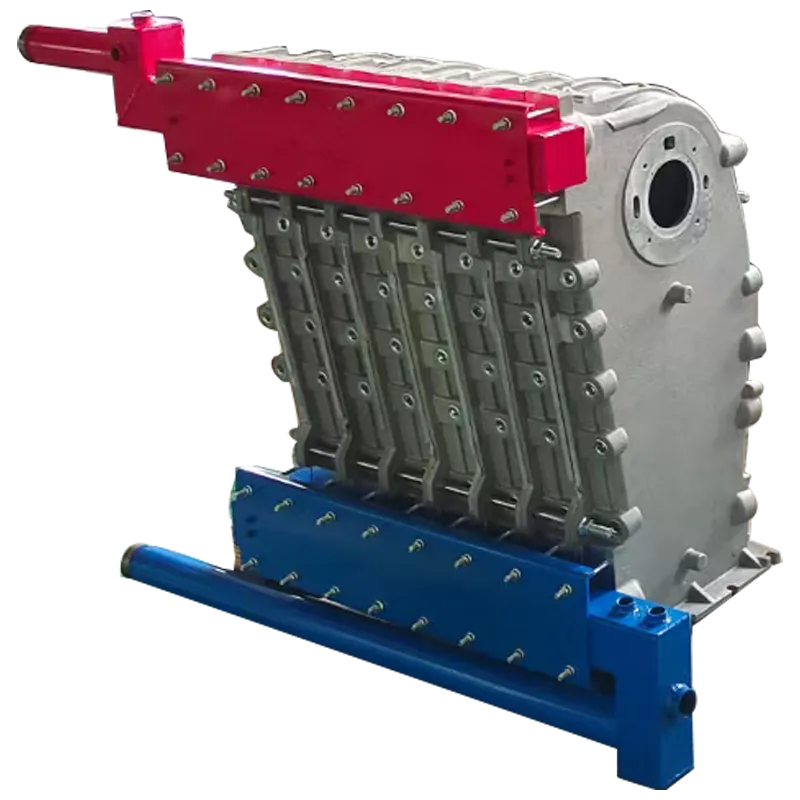

industrial heat exchanger

Industrial Heat Exchangers Essential Components in Thermal Management

Heat exchangers play a pivotal role in various industrial processes, making them indispensable components for efficient thermal management. These devices facilitate the transfer of heat between two or more fluids without them mixing, ensuring optimal energy consumption and maximizing operational efficiency.

In industries such as chemical manufacturing, oil refining, and power generation, heat exchangers are utilized to recover waste heat and enhance energy efficiency. By transferring heat from a hot fluid to a cooler one, these systems enable processes to operate at lower temperatures, which can significantly reduce fuel consumption and associated operational costs. For instance, in power plants, heat exchangers transfer heat from exhaust gases to water, converting it into steam for power generation, thus improving the overall efficiency of the plant.

There are several types of industrial heat exchangers, each designed for specific applications. The most common types include shell-and-tube, plate, air-cooled, and double-pipe heat exchangers. Shell-and-tube heat exchangers are widely used due to their robust design and ability to handle high pressure and temperature. Plate heat exchangers, on the other hand, offer high heat transfer coefficients in a compact design, making them ideal for applications where space is a concern. Air-cooled heat exchangers leverage ambient air to cool or heat fluids, providing an energy-efficient solution without the need for cooling water.

industrial heat exchanger

The selection of an appropriate heat exchanger depends on several factors, including the properties of the fluids involved, the required temperature change, space availability, and maintenance considerations. Engineers often employ computational fluid dynamics (CFD) simulations to optimize the design and predict performance, ensuring that the heat exchanger meets the specific needs of the application.

In addition to enhancing energy efficiency, industrial heat exchangers contribute significantly to environmental sustainability. By maximizing heat recovery, these systems reduce greenhouse gas emissions and the overall carbon footprint of industrial operations. Moreover, advancements in materials science and engineering are leading to the development of more efficient and durable heat exchangers, further supporting the move towards greener technologies.

In conclusion, industrial heat exchangers are crucial for optimizing energy use and enhancing productivity across various sectors. As industries continue to seek ways to improve efficiency and reduce environmental impact, the role of heat exchangers will undoubtedly become even more significant in the landscape of modern manufacturing and energy generation.

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025