Gru . 16, 2024 00:43 Back to list

Finding Reliable Suppliers for Lost Wax Casting Services and Solutions

The Lost Wax Wasting Technique A Comprehensive Overview for Suppliers

In the world of metallurgy and casting, precision and detail are paramount. The lost wax process, also known as investment casting, is an age-old method that has been refined over centuries to produce intricate and high-quality metal objects. This article explores the nuances of the lost wax wasting technique, particularly focusing on its significance for suppliers in the manufacturing and decorative industries.

What is Lost Wax Wasting?

Lost wax wasting is a volumetric production technique where a model is created using a material that can be melted away. Traditionally, this model was made from wax, but modern iterations may utilize other substances that can be easily removed. The process begins by creating a detailed mold of the original model. Once the mold is hardened, the wax is melted and drained away, leaving a cavity that precisely mirrors the original model’s dimensions. This cavity is then filled with molten metal to create the final product.

The Supplier's Role in Lost Wax Casting

Suppliers play a crucial role in the lost wax casting process. They provide the necessary materials, including wax, refractory materials for the molds, and quality metals suitable for casting. A reliable supplier must ensure that these materials not only meet industry standards but also possess qualities that enhance the final product's durability and aesthetic appeal.

Moreover, suppliers are often involved in the initial design phase, offering insights on how to optimize the casting process by utilizing materials that minimize waste and maximize the quality of the cast. For instance, they may suggest alternative wax compositions or faster hardening agents for molds based on their extensive market knowledge.

Benefits of Lost Wax Wasting for Suppliers

1. Precision and Detail Lost wax casting allows for remarkable accuracy in replicating complex designs. For suppliers, this ability to produce highly detailed components can open up vast markets, from jewelry to aerospace parts.

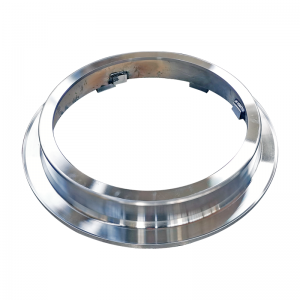

lost wax wasting supplier

2. Versatility The lost wax process can be used with a variety of materials, including precious metals, which allows suppliers to target diverse client needs across different industries.

3. Rapid Prototyping With advancements in technology, suppliers can now create prototypes quickly using lost wax techniques. This rapid development process enables faster turnaround times for clients, making suppliers more appealing partners.

4. Reduced Waste Compared to traditional casting methods, lost wax wasting can significantly reduce material waste. This not only represents cost savings for suppliers but also promotes a more sustainable approach to manufacturing.

Challenges Facing Suppliers

Despite the many advantages, suppliers in the lost wax wasting sector face challenges. The requirement for highly skilled labor to create intricate designs can lead to hiring difficulties. Additionally, fluctuations in metal prices can affect profit margins, making it essential for suppliers to have a flexible pricing strategy and robust relationships with metal providers.

Quality control is another critical concern. Since the lost wax method demands high precision, even minor defects in the mold or the casting process can result in substantial losses. Suppliers must therefore invest in quality assurance processes to meet customer expectations consistently.

Conclusion

The lost wax wasting process represents a blend of traditional craftsmanship and modern technology, making it a vital aspect of the manufacturing landscape. For suppliers, it offers opportunities to expand their market reach and improve their product offerings while also presenting certain challenges that require attention and innovation. As industries increasingly demand precision and quality, the adeptness of suppliers in navigating the nuances of lost wax casting will be an integral part of their success in this competitive field. By prioritizing material quality and customer collaboration, suppliers can ensure they remain at the forefront of the lost wax wasting technique.

-

Premium Cast Iron Water Main Pipe for Robust Infrastructure

NewsAug.27,2025

-

A-Rated Cast Aluminum Boilers: High-Efficiency Condensing Gas & LPG

NewsAug.26,2025

-

OEM Cast Silicon Aluminum Alloy Heat Exchanger | Custom & High Performance

NewsAug.25,2025

-

Centrifugally Cast Iron Water Main Pipe | Ductile Iron Solutions

NewsAug.24,2025

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025