Vas . 10, 2025 11:11 Back to list

power plant heat exchanger

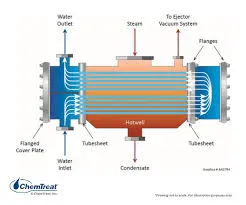

The power plant heat exchanger is a critical component in the energy production sector, playing an essential role in maximizing the efficiency and performance of power plants. Understanding this technology necessitates a dive into its core functions, applications, and the intricate balance it maintains in power generation systems.

In the realm of authority, it's paramount for power plant operators to stay abreast of the latest technological advancements in heat exchanger design. Innovations like microchannel heat exchangers and enhanced heat transfer surfaces have brought unprecedented improvements in efficiency and compactness. Consulting with experts who keep pace with these developments ensures that a power plant's operations remain competitive and environmentally compliant. Building trust within the industry, manufacturers of heat exchangers for power plants adhere to stringent international standards and certifications. These standards, such as the ASME Boiler and Pressure Vessel Code or ISO certifications, guarantee that the heat exchangers are up to par with global safety and performance expectations. Engaging with vetted manufacturers that meet these standards not only assures product quality but also instills confidence in stakeholders about the operational integrity of the power plant. Moreover, real-world application and performance data bolster the credibility of heat exchanger solutions. Case studies from power plants around the world provide empirical evidence of efficiency gains and cost savings achieved through the adoption of cutting-edge heat exchanger technology. Analyzing this data helps prospective buyers make informed decisions based on proven results rather than theoretical projections. In conclusion, power plant heat exchangers are a cornerstone of modern energy systems due to their vital role in improving efficiency and sustainability. When equipped with the latest advancements and selected based on precise expertise-driven decisions, these devices not only enhance the operational efficiency of power plants but also contribute to broader environmental goals. By prioritizing experience and expertise, while ensuring authoritativeness and trustworthiness through compliance and performance validation, stakeholders can optimize their power generation processes effectively.

In the realm of authority, it's paramount for power plant operators to stay abreast of the latest technological advancements in heat exchanger design. Innovations like microchannel heat exchangers and enhanced heat transfer surfaces have brought unprecedented improvements in efficiency and compactness. Consulting with experts who keep pace with these developments ensures that a power plant's operations remain competitive and environmentally compliant. Building trust within the industry, manufacturers of heat exchangers for power plants adhere to stringent international standards and certifications. These standards, such as the ASME Boiler and Pressure Vessel Code or ISO certifications, guarantee that the heat exchangers are up to par with global safety and performance expectations. Engaging with vetted manufacturers that meet these standards not only assures product quality but also instills confidence in stakeholders about the operational integrity of the power plant. Moreover, real-world application and performance data bolster the credibility of heat exchanger solutions. Case studies from power plants around the world provide empirical evidence of efficiency gains and cost savings achieved through the adoption of cutting-edge heat exchanger technology. Analyzing this data helps prospective buyers make informed decisions based on proven results rather than theoretical projections. In conclusion, power plant heat exchangers are a cornerstone of modern energy systems due to their vital role in improving efficiency and sustainability. When equipped with the latest advancements and selected based on precise expertise-driven decisions, these devices not only enhance the operational efficiency of power plants but also contribute to broader environmental goals. By prioritizing experience and expertise, while ensuring authoritativeness and trustworthiness through compliance and performance validation, stakeholders can optimize their power generation processes effectively.

Share

Pervious:

Latest news

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025