Gru . 12, 2024 21:30 Back to list

wholesale stainless steel impeller

Wholesale Stainless Steel Impellers Driving Efficiency in Industry

In the realm of industrial machinery and equipment, the importance of reliable and efficient components cannot be overstated. One such crucial component is the impeller, a device essential for transferring energy to a fluid, thus facilitating the movement of liquids or gases within various systems. Among the multitude of materials used in the manufacture of impellers, stainless steel has emerged as a favored choice due to its superior properties. This article explores the benefits and applications of wholesale stainless steel impellers, shedding light on their significance in modern industrial practices.

The Advantages of Stainless Steel Impellers

Stainless steel impellers offer numerous advantages over those made from other materials. One of the primary benefits is their exceptional resistance to corrosion. In many industrial environments, impellers must operate in challenging conditions, often involving exposure to aggressive chemicals or high humidity. Stainless steel's inherent resistance to rust and corrosion ensures longevity and performance even in the most demanding applications.

Moreover, stainless steel impellers possess a high strength-to-weight ratio, making them both durable and lightweight. This characteristic is particularly important in applications requiring high efficiency, as the reduced weight can lead to lower energy consumption when driven by motors or turbines. Additionally, the mechanical strength of stainless steel allows for the creation of impellers that can handle significant pressures and flow rates, making them suitable for a variety of industrial processes.

Another significant advantage is the ease of maintenance associated with stainless steel components. Their smooth surfaces and resistance to staining make cleaning straightforward, ensuring that they remain in optimal working condition. This ease of maintenance translates into lower operational costs and reduced downtime, factors that are critical in competitive markets.

Applications of Wholesale Stainless Steel Impellers

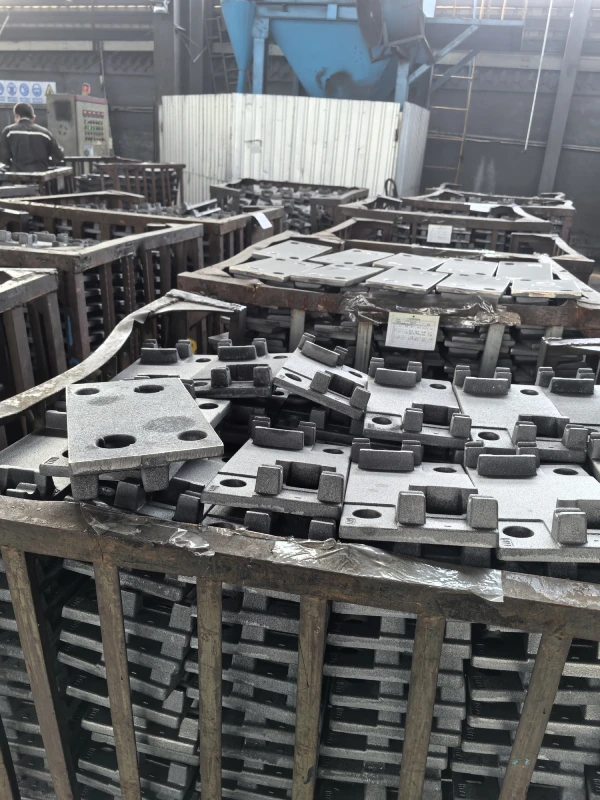

wholesale stainless steel impeller

The versatility of stainless steel impellers is evident in their wide range of applications across various industries. In the manufacturing sector, they are commonly used in pumps, compressors, and mixers. For example, in the food and beverage industry, stainless steel impellers are vital components for processing equipment, ensuring the safe and efficient movement of products without contamination.

In the chemical manufacturing sector, the durability and resistance to harsh chemicals make stainless steel impellers an ideal choice for reactors and agitators. They can withstand the rigors of continuous operation while maintaining performance standards that are crucial for product quality and safety.

Additionally, in the water treatment industry, wholesale stainless steel impellers are employed in pumps and aeration systems, playing a vital role in the purification process. Their resistance to biofouling and corrosion ensures that the systems remain functional over extended periods, contributing to effective water management solutions.

The Wholesale Perspective

Purchasing stainless steel impellers in bulk can lead to significant cost savings for businesses. Wholesalers often provide competitive pricing, allowing companies to procure high-quality components without straining their budgets. Moreover, sourcing from reputable suppliers ensures that manufacturers receive products that meet industry standards and certifications.

In conclusion, wholesale stainless steel impellers represent an essential component in a wide range of industrial applications. Their superior properties, such as corrosion resistance, strength, and ease of maintenance, make them a preferred choice in challenging environments. As industries continue to evolve and demand higher efficiency, the significance of investing in durable and reliable components like stainless steel impellers cannot be overlooked. For businesses looking to enhance productivity and performance, the adoption of these advanced impellers could be a strategic move toward achieving long-term success.

-

Premium Cast Iron Water Main Pipe for Robust Infrastructure

NewsAug.27,2025

-

A-Rated Cast Aluminum Boilers: High-Efficiency Condensing Gas & LPG

NewsAug.26,2025

-

OEM Cast Silicon Aluminum Alloy Heat Exchanger | Custom & High Performance

NewsAug.25,2025

-

Centrifugally Cast Iron Water Main Pipe | Ductile Iron Solutions

NewsAug.24,2025

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025