Дек . 19, 2024 04:36 Back to list

cast silicon aluminum heat exchanger for domestic heating boiler exporters

Cast Silicon Aluminum Heat Exchanger for Domestic Heating Boiler Exporters

The demand for efficient heating solutions, particularly in domestic environments, has led to the increasing popularity of advanced materials and technologies in the heating industry. Among these, cast silicon aluminum heat exchangers have emerged as a significant player in optimizing boiler performance for domestic heating systems. This article provides an overview of the characteristics, benefits, and export market of cast silicon aluminum heat exchangers for domestic heating boilers.

Understanding Cast Silicon Aluminum Heat Exchangers

Cast silicon aluminum is a specialized alloy that boasts superior thermal conductivity and corrosion resistance. This makes it an ideal material for heat exchangers, which are critical components in domestic heating systems. In essence, heat exchangers allow for efficient heat transfer from one medium to another, ensuring that homes remain warm and comfortable during colder months.

The unique composition of cast silicon aluminum includes a significant percentage of silicon, which enhances the material’s fluidity during the casting process. This allows for intricate designs and compact structures, resulting in more efficient space utilization in boiler systems. The alloy's durability also ensures longevity, reducing the need for frequent replacements and maintenance, which is a crucial consideration for homeowners.

Benefits of Cast Silicon Aluminum Heat Exchangers

1. Enhanced Thermal Efficiency The primary function of a heat exchanger is to maximize thermal transfer. Cast silicon aluminum’s excellent thermal conductivity ensures that a greater amount of heat is transferred from the heated fluid to the water in the boiler, improving overall efficiency.

2. Corrosion Resistance One of the major challenges facing heat exchangers is corrosion, especially in environments where water quality may vary. The corrosion resistance of cast silicon aluminum extends the lifespan of heat exchangers, making them a reliable choice for domestic heating solutions.

3. Lightweight and Compact Design The lightweight nature of this alloy allows manufacturers to create slimmer and more compact designs. This not only makes installation easier but also enables the integration of heat exchangers in tighter spaces within homes.

cast silicon aluminum heat exchanger for domestic heating boiler exporters

4. Cost-Effectiveness While the initial investment in cast silicon aluminum heat exchangers may be higher than traditional materials, the long-term savings achieved through increased energy efficiency and reduced maintenance costs make them an economically sound option for homeowners.

5. Environmental Compliance With growing concerns surrounding energy efficiency and environmental impact, using advanced materials like cast silicon aluminum aligns with global trends aimed at reducing carbon footprints. These heat exchangers can operate efficiently at lower temperatures, further minimizing energy consumption.

Export Opportunities

As the global market for domestic heating solutions expands, there is a thriving demand for high-quality heat exchangers. Exporters focusing on cast silicon aluminum heat exchangers have significant opportunities to tap into various international markets, especially in regions experiencing colder climates or those with stringent energy efficiency regulations.

Countries in Europe, North America, and parts of Asia are increasingly seeking innovative heating solutions that not only comply with regulations but also offer enhanced performance. Exporters can leverage the benefits of cast silicon aluminum, presenting it as a superior alternative to traditional materials.

Furthermore, networking with domestic manufacturers and building partnerships can facilitate smoother entry into new markets. Attending trade fairs, participating in industry conferences, and engaging with relevant trade associations can open doors for exporters and showcase the benefits of their products to a wider audience.

Conclusion

Cast silicon aluminum heat exchangers represent a significant advancement in the field of domestic heating. With numerous advantages such as enhanced thermal efficiency, corrosion resistance, and a lightweight design, they stand out as a preferred choice for modern boilers. For exporters, capitalizing on the growing demand for these innovative solutions may present a lucrative opportunity in an increasingly competitive market. As the world moves toward more sustainable and efficient heating technologies, cast silicon aluminum heat exchangers are poised to play a leading role in the future of domestic heating systems.

-

Centrifugally Cast Iron Water Main Pipe | Ductile Iron Solutions

NewsAug.24,2025

-

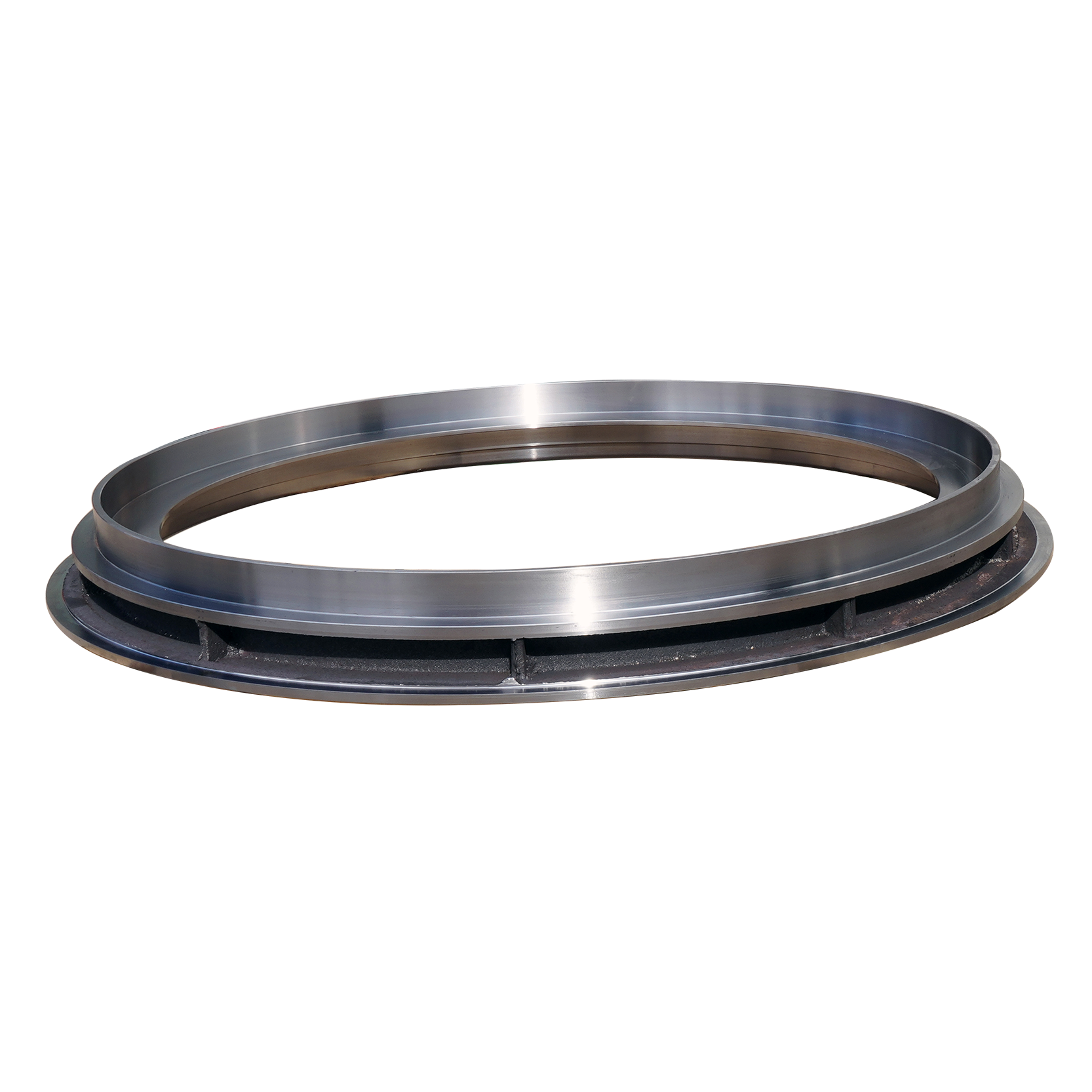

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025