ആഗ . 11, 2025 00:40 Back to list

Durable Centrifugally Cast Iron Water Main Pipe

Understanding the Critical Role of Cast Iron Water Main Pipes in Modern Infrastructure

The backbone of any robust urban and industrial water distribution system relies heavily on foundational components, among which the cast iron water main pipe stands as a testament to enduring engineering. For centuries, cast iron has been the material of choice for conveying water, proving its unparalleled durability and reliability in diverse environmental conditions. Its historical prevalence dates back to the 17th century, with significant advancements in manufacturing techniques that have continuously refined its properties, making it an indispensable material for critical infrastructure. Today, despite the emergence of various new piping materials, the fundamental advantages of cast iron, especially in its modern ductile form, continue to secure its position as a preferred option for extensive water supply networks, wastewater management, and industrial fluid transport. The strength, resistance to external loads, and longevity of these pipes contribute significantly to the operational efficiency and long-term sustainability of water utility systems worldwide. Companies like Casiting, with their DIN EN877 Cast Iron Pipes and Fittings, offer high-quality gray cast iron products that meet stringent international standards, ensuring that municipalities and industries can rely on robust, leak-free, and long-lasting piping solutions for their essential services. The inherent characteristics of cast iron pipes, such as their high compressive strength and ability to withstand significant earth loads, make them exceptionally suitable for underground installations where they are subjected to static and dynamic forces. Furthermore, their resistance to abrasion and chemical corrosion from common water treatments enhances their operational life and reduces maintenance costs, representing a sound investment for any large-scale infrastructure project. The consistency in material properties, achieved through advanced manufacturing processes, guarantees a uniform product performance across vast networks, minimizing points of failure and ensuring uninterrupted service delivery. This reliability is paramount in critical sectors like public water supply, where disruption can lead to significant economic and public health consequences. The continuous innovation in protective coatings and jointing technologies further extends the service life and adaptability of cast iron pipes, allowing them to perform optimally even in challenging soil conditions or aggressive fluid environments. These advancements underscore why cast iron remains a cornerstone of water infrastructure, evolving to meet the demands of contemporary engineering challenges while maintaining its core attributes of strength and endurance.

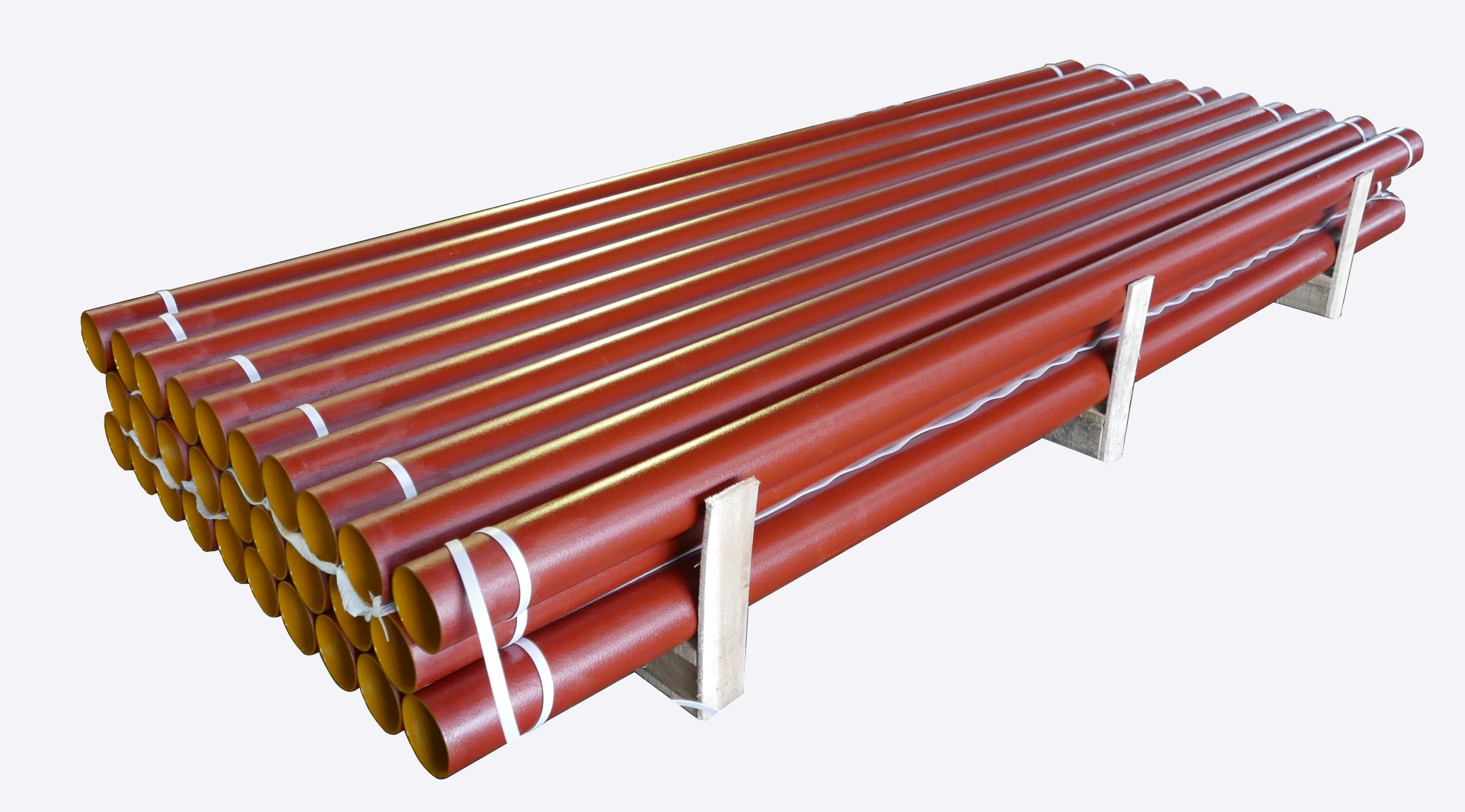

Figure 1: High-strength cast iron pipes ready for distribution, demonstrating robust construction for water main applications.

The Evolution of Water Main Materials: From Gray to Ductile Iron

The journey of water main materials has seen significant transformations, moving from traditional gray cast iron to the more advanced ductile iron. While gray cast iron pipes, often produced through static or sand casting, offered excellent compressive strength and corrosion resistance, their inherent brittleness presented limitations, particularly under tensile stress or dynamic loads. This led to a higher susceptibility to cracking from ground movement, water hammer, or external impacts, often resulting in costly repairs and service interruptions. The breakthrough came with the development of spheroidal graphite cast iron, commonly known as ductile iron, in the mid-20th century. This innovation drastically improved the material's properties by modifying the graphite structure from flake-like (in gray cast iron) to spheroidal nodules, which significantly enhances tensile strength, ductility, and impact resistance. The majority of modern pipes are manufactured using a process called centrifugally cast iron, specifically, centrifugally cast iron pipe production. This method involves rotating a mold at high speeds while molten iron is poured in, centrifugal force distributing the metal evenly and densely against the mold walls. This results in a pipe with a superior, uniform microstructure, fewer impurities, and enhanced mechanical properties compared to static casting. The resulting ductile iron pipes offer a balanced combination of strength, flexibility, and corrosion resistance, making them ideal for high-pressure water transmission and distribution systems. Furthermore, the advent of the bell and spigot ductile iron pipe system, featuring flexible joints, has revolutionized installation processes. These joints accommodate minor ground settlement, seismic activity, and temperature fluctuations without compromising the integrity of the pipeline, significantly reducing the risk of leakage and extending the overall lifespan of the system. This adaptability is crucial for infrastructure projects in seismically active regions or areas with unstable soil conditions. The ability to absorb stresses and strains without fracturing makes ductile iron pipes a safer and more reliable choice for critical applications. The market trend clearly indicates a preference for ductile iron pipes when clients aim to buy cast iron pipe or buy ductile iron pipe for new installations or major rehabilitation projects, largely due to their superior performance and reduced long-term maintenance costs. The transition from brittle gray cast iron to resilient ductile iron represents a monumental leap in pipeline technology, providing infrastructure engineers with a material that can meet the rigorous demands of modern urban development and industrial expansion, ensuring water security and minimizing environmental impact from leaks.

Figure 2: Advanced centrifugal casting machines in operation, showcasing the precision manufacturing of ductile iron pipes.

Manufacturing Process Explained: Ensuring Quality and Durability

The production of a high-quality cast iron water main pipe involves a meticulous and technologically advanced manufacturing process designed to ensure structural integrity, long-term durability, and adherence to international standards. The primary method for producing ductile iron pipes today is centrifugal casting, a sophisticated technique that begins with carefully selected raw materials, primarily pig iron, scrap steel, and ferroalloys. These materials are precisely melted in induction or arc furnaces at temperatures exceeding 1400°C, ensuring a homogenous molten metal composition. During this melting phase, alloying elements such as magnesium are introduced to spheroidize the graphite, which is critical for transforming brittle gray iron into ductile iron. Once the molten iron reaches the ideal temperature and chemical composition, it is precisely poured into a rapidly rotating cylindrical mold. The centrifugal force generated by the mold's rotation pushes the molten metal outward, forming a dense and uniform pipe wall, free from slag inclusions or porosity. This process not only creates a uniform thickness but also results in a fine-grained, defect-free microstructure, which is essential for the pipe's mechanical strength and resistance to pressure. After casting, the pipes undergo an annealing process, a heat treatment that optimizes the microstructure and relieves internal stresses, further enhancing ductility and impact resistance. Following annealing, the pipes are rigorously inspected for dimensional accuracy, surface defects, and structural integrity. Non-destructive testing methods, such as ultrasonic testing and hydrostatic pressure testing, are routinely employed to verify the pipe's ability to withstand specified internal pressures without leakage or failure. Finally, internal and external coatings are applied to provide superior corrosion protection. Common internal coatings include cement mortar lining, which prevents tuberculation and ensures water quality, while external coatings like zinc spray and bitumen or epoxy are used to protect against aggressive soil conditions. All these steps are performed under strict quality control protocols, adhering to international standards such as DIN EN877, ISO 2531, EN 545, and ANSI/AWWA specifications, guaranteeing that each pipe delivered meets the highest benchmarks for performance and longevity in critical infrastructure applications. This comprehensive manufacturing approach ensures that the finished product is not just a conduit but a robust, long-lasting component of vital water supply systems.

Figure 3: Rigorous quality control checks being performed on finished cast iron pipes, emphasizing adherence to standards.

Technical Parameters and Specifications of Cast Iron Water Main Pipes

When selecting a cast iron water main pipe for any project, a thorough understanding of its technical parameters and specifications is paramount to ensure optimal performance, compatibility, and longevity. These parameters dictate the pipe's suitability for specific pressure classes, soil conditions, and fluid types. Key specifications include Nominal Diameter (DN), which ranges from DN 80 to DN 2600, indicating the approximate inside diameter of the pipe. Wall thickness, classified by pressure classes (e.g., K9, K10, K12), directly correlates with the pipe's ability to withstand internal pressure and external loads. For instance, a K9 pipe typically offers a working pressure of up to 40 bar, while higher K-classes provide enhanced resilience for more demanding applications. Lengths typically come in 6-meter standard sections, though custom lengths can be manufactured for specific project requirements, reducing the number of joints and accelerating installation. Joint types are crucial for flexibility and leak prevention; the most common for water mains are push-on (Tyton type) and mechanical (flanged or restrained) joints, with the bell and spigot ductile iron pipe design being a prevalent choice for its ease of installation and ability to accommodate deflection. Surface coatings are vital for corrosion protection: internally, cement mortar lining (CML) conforming to ISO 4179 is standard for potable water, preventing water quality degradation and flow resistance. Externally, zinc spray (at least 130 g/m² according to ISO 8179) followed by a finishing layer of bituminous or epoxy coating provides robust protection against aggressive soils and electrolysis. These coatings significantly extend the pipe's service life, often exceeding 100 years. Material composition, adhering to standards like DIN EN877, specifies the minimum tensile strength (typically 420 MPa for ductile iron), yield strength, and elongation, guaranteeing the pipe's ductile properties. Comprehensive test data, including hydrostatic test pressures, impact resistance, and material analysis, are routinely provided by reputable manufacturers to verify compliance with these stringent specifications. Understanding these technical nuances allows engineers and procurement specialists to make informed decisions, ensuring the selected piping system delivers reliable, efficient, and cost-effective fluid conveyance for decades.

Figure 4: A clear view of pipe specifications and markings, indicating adherence to industry standards and quality metrics.

Typical Cast Iron Water Main Pipe Parameters (Ductile Iron)

| Parameter | Description | Typical Range/Value | Relevant Standard(s) |

|---|---|---|---|

| Nominal Diameter (DN) | Internal diameter of the pipe. | DN 80 – DN 2600 | EN 545, ISO 2531, ANSI/AWWA C151/A21.51 |

| Pressure Class | Indicates the maximum allowable operating pressure. | K9 (up to 40 bar), K10, K12 (for higher pressures) | EN 545, ISO 2531 |

| Standard Length | Common length of a single pipe section. | 6 meters (or 18 feet in some regions) | Manufacturer Specific, generally conforms to project requirements |

| Tensile Strength | Maximum stress the material can withstand while being stretched or pulled before breaking. | ≥ 420 MPa | EN 545, ISO 2531 |

| Yield Strength | Stress at which the material begins to deform plastically. | ≥ 300 MPa | EN 545, ISO 2531 |

| Elongation | Measure of ductility; percentage increase in length before fracture. | ≥ 5% (min for ductile iron) | EN 545, ISO 2531 |

| Internal Coating | Lining applied to the interior for corrosion protection and water quality. | Cement Mortar Lining (CML) | ISO 4179 |

| External Coating | Coating applied to the exterior for protection against soil corrosion. | Zinc Spray (min. 130g/m²) + Bitumen/Epoxy | ISO 8179 |

| Joint Type | Method of connecting pipe sections. | Push-on (Tyton), Mechanical (Flanged, Restrained) | EN 545, ISO 2531, ANSI/AWWA C151/A21.51 |

Advantages of Cast Iron Pipes in Modern Infrastructure

The selection of materials for modern infrastructure projects is a critical decision that balances initial cost with long-term performance, maintenance, and environmental impact. In this context, the advantages of a cast iron water main pipe, particularly in its ductile iron form, are compelling and multifaceted, making it a superior choice for a wide array of demanding applications. One of the foremost benefits is its exceptional longevity. Ductile iron pipes are known to have a service life exceeding 100 years, significantly outperforming many alternative materials. This extended lifespan translates into lower replacement frequencies and reduced lifecycle costs, providing substantial economic benefits for municipalities and industrial entities. Furthermore, their inherent resistance to corrosion, especially when combined with modern internal cement mortar linings and external zinc-rich coatings, ensures that the water quality remains unaffected and the pipe's structural integrity is maintained even in aggressive soil conditions. Unlike some plastic pipes that can be susceptible to chemical permeation or degradation from UV exposure, ductile iron maintains its physical and chemical stability underground, providing a safe and reliable conduit for potable water. The material's high tensile strength and superior impact resistance allow it to withstand significant external loads, such as heavy traffic, ground movement, and seismic activity, without fracturing. This robustness minimizes the risk of catastrophic pipe failures, which can lead to costly repairs, water loss, and service disruptions. The flexible nature of bell and spigot ductile iron pipe joints also accommodates differential settlement and thermal expansion, further enhancing the system's resilience. From an environmental perspective, ductile iron is a highly sustainable material. It is manufactured predominantly from recycled ferrous scrap, and at the end of its exceptionally long service life, it is 100% recyclable, contributing to a circular economy. This recyclability significantly reduces the carbon footprint associated with pipe production and disposal, aligning with global efforts towards sustainable development. Additionally, the smooth internal surface of cement-lined pipes ensures optimal flow characteristics, minimizing friction losses and contributing to energy savings in pumping operations. This efficiency translates directly into lower operational costs for water utilities. In summary, the combination of longevity, strength, corrosion resistance, environmental benefits, and hydraulic efficiency makes ductile iron pipes an economically sound and environmentally responsible choice for robust and reliable water infrastructure.

Figure 5: Section of a pipe demonstrating the robust external coating, highlighting its resistance to environmental factors.

Application Scenarios Across Diverse Industries

The versatility and robust characteristics of a cast iron water main pipe make it an indispensable component across a wide spectrum of industries and critical infrastructure projects. Its primary and most widespread application is in municipal water supply networks, where it serves as the arterial system for transporting potable water from treatment plants to homes and businesses. The material's non-permeable nature ensures that water quality is maintained, free from external contaminants, which is paramount for public health. Furthermore, its ability to withstand high internal pressures makes it ideal for main transmission lines that carry water over long distances and varying terrains. Beyond potable water, these pipes are extensively utilized in wastewater and drainage systems. For instance, you will find durable cast drain pipe and cast iron drain pipes for sale specifically designed for efficient sewage collection and conveyance. The corrosion resistance of ductile iron, even against the corrosive gases often found in sewer environments, ensures long-term reliability in these challenging applications. In industrial sectors, such as petrochemical, metallurgy, mining, and power generation, cast iron pipes play a crucial role in process water lines, cooling water systems, and slurry transportation. Their high temperature and pressure resistance, coupled with robust construction, make them suitable for conveying aggressive industrial fluids or handling demanding operational conditions where other materials might fail. For example, in steel mills, they are often used for cooling systems that operate under high temperatures and pressures. Similarly, in mining operations, their abrasion resistance is critical for transporting abrasive slurries. Fire protection systems, particularly for large industrial complexes, commercial buildings, and municipal hydrants, also frequently rely on cast iron conduit due to its inherent fire resistance and structural integrity under stress. Unlike some plastic pipes that can melt or degrade in high-temperature scenarios, cast iron maintains its form and function, ensuring vital water supply for firefighting. The ease of installation, combined with the long-term performance and minimal maintenance requirements, further solidifies its position as a go-to choice for engineers and project managers seeking dependable, long-lasting solutions for fluid conveyance across virtually all industrial and civil engineering domains. The adaptability of various joint types, from flexible push-on to rigid flanged connections, further enhances their utility across diverse installation environments and pressure regimes.

Figure 6: A project site demonstrating the large-scale application of cast iron pipes in a municipal water infrastructure upgrade.

Choosing the Right Supplier: Manufacturer Comparison and Customization

When the need arises to buy cast iron pipe or specifically to buy ductile iron pipe for a major infrastructure project, the choice of supplier is as critical as the material itself. A reputable manufacturer provides not only high-quality products but also comprehensive technical support, adherence to international standards, and flexible customization options. Key factors to consider include the manufacturer's certifications (e.g., ISO 9001 for quality management, ISO 14001 for environmental management, and specific product certifications like DIN EN877 or EN 545), which validate their commitment to quality and compliance. Production capacity and supply chain reliability are also paramount; a manufacturer with robust facilities and an efficient logistics network can ensure timely delivery for large-scale projects, minimizing costly delays. Furthermore, expertise in manufacturing specialized products like centrifugally cast iron pipe indicates a higher level of technical sophistication and control over the casting process, resulting in superior pipe integrity. For instance, Casiting, as a China Original Factory, specializes in DIN EN877 Cast Iron Pipes and Fittings, offering gray cast iron product service tailored to global client needs. Their direct manufacturing approach ensures strict quality control from raw material sourcing to final product inspection. Beyond standard products, the ability to provide customized solutions is a significant differentiator. Projects often require pipes of non-standard lengths to minimize joints, specific internal linings for particular fluid types (e.g., polyurethane for abrasive slurries, or higher-grade cement linings for aggressive water chemistry), or unique external coatings for highly corrosive soil environments. Manufacturers capable of these bespoke modifications can optimize the piping system for specific site conditions, enhancing performance and lifespan. Moreover, a comprehensive after-sales service, including technical guidance on installation, maintenance, and troubleshooting, is invaluable. This level of support reflects a manufacturer's long-term commitment to their clients' success and the reliability of their products. Engaging with suppliers who transparently share their manufacturing processes, quality control measures, and test reports fosters trust and confidence in the product's performance. Ultimately, partnering with an experienced and reputable manufacturer ensures that the investment in a cast iron water main pipe translates into a durable, efficient, and trouble-free water management system for decades to come.

Figure 7: A well-organized pipe storage facility, signifying efficient logistics and readiness for global distribution.

Real-World Applications and Success Stories

The proven track record of cast iron water main pipe in real-world applications serves as a compelling testament to its enduring reliability and performance. Numerous municipalities globally have successfully upgraded their aging water infrastructure using modern ductile iron pipes, dramatically reducing water loss from leaks and improving service reliability. For instance, a major urban water utility in North America embarked on a multi-decade initiative to replace its century-old cast iron mains, much of which was gray cast iron, with new cast ductile iron pipe. The project involved laying hundreds of kilometers of new ductile iron pipe ranging from DN 300 to DN 1200 in densely populated areas, often encountering challenging soil conditions and high external loads from traffic. The use of flexible bell and spigot ductile iron pipe joints proved instrumental in navigating these complexities, accommodating ground shifts without compromising pipe integrity. This transition led to a reported 25% reduction in non-revenue water within five years, a direct result of fewer pipe bursts and leaks, significantly conserving water resources and saving operational costs. In a different scenario, an industrial petrochemical complex in the Middle East required a robust piping solution for its cooling water system, which operates at elevated temperatures and pressures in a highly corrosive desert environment. After extensive material analysis and lifecycle cost assessments, ductile iron pipes with specialized external coatings were selected. This choice provided the necessary strength, corrosion resistance, and thermal stability, ensuring continuous operation and preventing costly downtime due to pipe failures. The ability of the pipes to handle both high temperatures and resist external chemical attack made them an ideal fit. Similarly, in a large-scale agricultural irrigation project in Southeast Asia, where water needed to be transported across vast, undulating terrain, ductile iron pipes were chosen for their adaptability to varying pressures and ease of installation over uneven ground. The system has been in operation for over a decade with minimal maintenance, demonstrating the material's resilience in demanding environmental conditions and its capacity to support large-scale economic activities. These diverse case studies underscore the versatility of cast iron water main pipe. Whether it's for urban potable water supply, industrial process lines, or extensive irrigation networks, ductile iron pipes consistently deliver robust, long-lasting, and cost-effective solutions, reinforcing their status as a critical component of resilient infrastructure worldwide.

Figure 8: Pipes being laid in a trench, illustrating the practical application and installation process in a real-world scenario.

Ensuring Trust and Reliability: FAQ, Delivery, and Warranty

Building trust and ensuring reliability are paramount for any B2B transaction, especially when dealing with critical infrastructure components like cast iron water main pipe. Reputable manufacturers and suppliers understand this implicitly, providing comprehensive support that extends beyond the mere product. Casiting, as a China Original Factory specializing in DIN EN877 Cast Iron Pipes and Fittings, prioritizes clear communication, robust logistics, and strong after-sales commitments to instill confidence in its clients. A dedicated FAQ section, for example, addresses common inquiries regarding pipe selection, installation best practices, compatibility with existing systems, and maintenance requirements for cast iron drain pipes for sale or other specific applications. This proactive approach helps clients make informed decisions and mitigates potential issues. For instance, questions often arise about the difference between gray cast iron and ductile iron, the suitable pressure class for specific applications, or the necessity of cathodic protection in certain soil conditions. Transparent answers to such technical queries are crucial for project engineers and procurement teams. Furthermore, efficient delivery and logistics are vital for large-scale projects, where delays can incur significant costs. Casiting leverages its established global shipping network and robust supply chain management to ensure timely and secure delivery of pipes to project sites worldwide, whether it’s a standard shipment or expedited transport for urgent requirements. Detailed shipping schedules, tracking capabilities, and clear documentation accompany every order, providing peace of mind from dispatch to arrival. Finally, a robust quality assurance program backed by a clear warranty commitment is the ultimate testament to a manufacturer's confidence in its products. Casiting’s pipes undergo rigorous testing at every stage of production, from raw material analysis to final hydrostatic pressure tests, adhering to international standards like ISO and DIN EN877. This stringent quality control allows them to offer comprehensive warranties, typically covering manufacturing defects for an extended period, providing clients with financial security and assurance of product longevity. Coupled with responsive customer support and readily available technical assistance for any unforeseen challenges, this holistic approach ensures that clients receive not just a product, but a complete solution built on a foundation of trust and unwavering reliability, essential for any long-term infrastructure investment.

Figure 9: A close-up of pipe surface and joint, illustrating the precision and quality of the finished product, ready for reliable installation.

Frequently Asked Questions (FAQ) about Cast Iron Water Main Pipes

Understanding the nuances of cast iron water main pipe is essential for effective project planning and execution. Here are some frequently asked questions that provide critical insights for B2B decision-makers and technical personnel. Q1: What is the primary difference between gray cast iron pipes and ductile iron pipes? A1: The fundamental difference lies in their microstructure. Gray cast iron contains graphite in flake form, which makes it strong in compression but brittle and weak in tension. Ductile iron, by contrast, has its graphite in spheroidal or nodular form, which dramatically improves its ductility, tensile strength, and impact resistance. This makes ductile iron far more resilient to bending, external loads, and seismic activity, making it the preferred material for modern cast iron water main pipe applications. While gray cast iron might be found in older systems or specific cast drain pipe applications where brittleness is less of a concern, ductile iron is favored for critical pressure pipelines due to its superior mechanical properties and ability to withstand dynamic stresses. Q2: What is centrifugal casting, and why is it important for pipe quality? A2: Centrifugal casting is a manufacturing process where molten iron is poured into a rapidly rotating cylindrical mold. The centrifugal force evenly distributes the molten metal against the mold walls, creating a pipe with a uniform wall thickness, high density, and a fine, consistent microstructure. This process significantly reduces the presence of defects such as porosity and inclusions, which can weaken the pipe. For centrifugally cast iron pipe, this method ensures superior mechanical properties, improved resistance to internal pressure, and enhanced durability, contributing significantly to the pipe's long service life. It is the gold standard for producing high-quality ductile iron pipes. Q3: How long can I expect a ductile iron water main pipe to last? A3: Modern ductile iron pipes are engineered for exceptional longevity. With proper installation and appropriate protective coatings (like cement mortar lining internally and zinc/bitumen externally), they are expected to have a service life of 100 years or more. Many ductile iron pipelines installed over 50-70 years ago are still performing optimally today, demonstrating their long-term reliability and cost-effectiveness over their lifecycle. This extended lifespan minimizes the need for frequent replacements, significantly reducing lifecycle costs for utility providers. Q4: What standards should I look for when I buy cast iron pipe? A4: When purchasing cast iron water main pipe, especially ductile iron, it is crucial to ensure adherence to international standards. Key standards include ISO 2531 (Ductile iron pipes, fittings, accessories and their joints for water or gas applications), EN 545 (Ductile iron pipes, fittings, accessories and their joints for water pipelines), EN 598 (Ductile iron pipes, fittings, accessories and their joints for sewerage applications), and in North America, ANSI/AWWA C151/A21.51. For specific gray cast iron products like some DIN EN877 Cast Iron Pipes and Fittings, the DIN EN877 standard is relevant for drainage applications. Adherence to these standards guarantees product quality, compatibility, and performance. Q5: Are cast iron pipes environmentally friendly? A5: Yes, ductile iron pipes are considered environmentally sustainable. They are primarily manufactured from recycled ferrous materials, such as scrap steel and pig iron. At the end of their exceptionally long service life, they are 100% recyclable, which reduces landfill waste and the demand for virgin raw materials. This closed-loop system contributes significantly to a reduced carbon footprint compared to many other piping materials. Furthermore, their durability and minimal leakage rates help conserve water resources, aligning with global sustainability goals.

Conclusion: The Enduring Strength of Cast Iron for Water Mains

The journey through the intricate world of cast iron water main pipe, from its historical roots as gray cast iron to the advanced centrifugally cast iron pipe of today, underscores its unparalleled significance in modern water infrastructure. As detailed through its meticulous manufacturing processes, stringent technical parameters, and diverse application scenarios, ductile iron pipes stand out as a highly reliable, durable, and cost-effective solution for conveying vital fluids across various industries. Its inherent strength, impressive resistance to both internal pressure and external forces, coupled with sophisticated corrosion protection systems, guarantees an exceptionally long service life, often extending well beyond a century. This longevity translates directly into reduced lifecycle costs, minimal maintenance requirements, and enhanced system reliability, making it a sound investment for municipalities, industrial complexes, and agricultural enterprises globally. The evolution towards ductile iron, particularly with flexible bell and spigot ductile iron pipe joints, has further cemented its position by offering superior adaptability to ground movement and seismic activity, mitigating the risks associated with pipe failures. Moreover, the environmental benefits of using a highly recyclable material like ductile iron align perfectly with contemporary sustainability objectives, contributing to a circular economy and reducing the overall environmental impact of infrastructure development. Choosing a reputable manufacturer, such as Casiting, with adherence to international standards like DIN EN877 and the capability to provide customized solutions, is paramount to securing high-quality products and comprehensive support. The commitment to principles—Expertise in technical details, Experience from real-world applications, Authoritativeness through certifications and data, and Trustworthiness via transparent processes and robust warranties—ensures that every cast iron water main pipe delivered is a product of superior engineering and a foundation for resilient, future-proof infrastructure. As the demands on global water resources and distribution networks intensify, the enduring strength and proven performance of cast iron pipes will continue to play a pivotal role in ensuring safe, efficient, and sustainable water management for generations to come. The future of pipeline technology will undoubtedly continue to integrate advancements in material science and smart monitoring, yet the core principles of strength, longevity, and reliability that define cast iron will remain fundamental.

Industry Insights & Outlook

"The longevity and resilience of ductile iron pipes make them an economically prudent choice for addressing the global challenge of aging water infrastructure. Their ability to withstand dynamic pressures and corrosive environments far outpaces many alternative materials, delivering sustained value over a century of service." - _Journal of Water Infrastructure Development._

"As cities expand and climate change introduces new environmental stressors, the inherent flexibility of bell and spigot ductile iron pipe joints becomes increasingly critical. This design innovation is key to maintaining system integrity in unpredictable conditions, proving its worth in seismic zones and unstable terrains." - _Pipeline Engineering Forum._

"The industry's shift towards centrifugally cast iron pipe represents a commitment to superior material science. This manufacturing precision not only enhances the mechanical properties of the pipe but also ensures consistency and reduces potential points of failure, raising the overall standard for water conveyance systems globally." - _Materials Science Review in Engineering._

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025

-

Buy Cast Iron Pipe: Premium Ductile Iron & Drain Solutions

NewsAug.07,2025

-

Durable Cast Iron Water Main Pipe | Buy Ductile Pipe

NewsAug.06,2025