ഡിസം . 12, 2024 11:44 Back to list

railway accessory ductile iron casting manufacturers

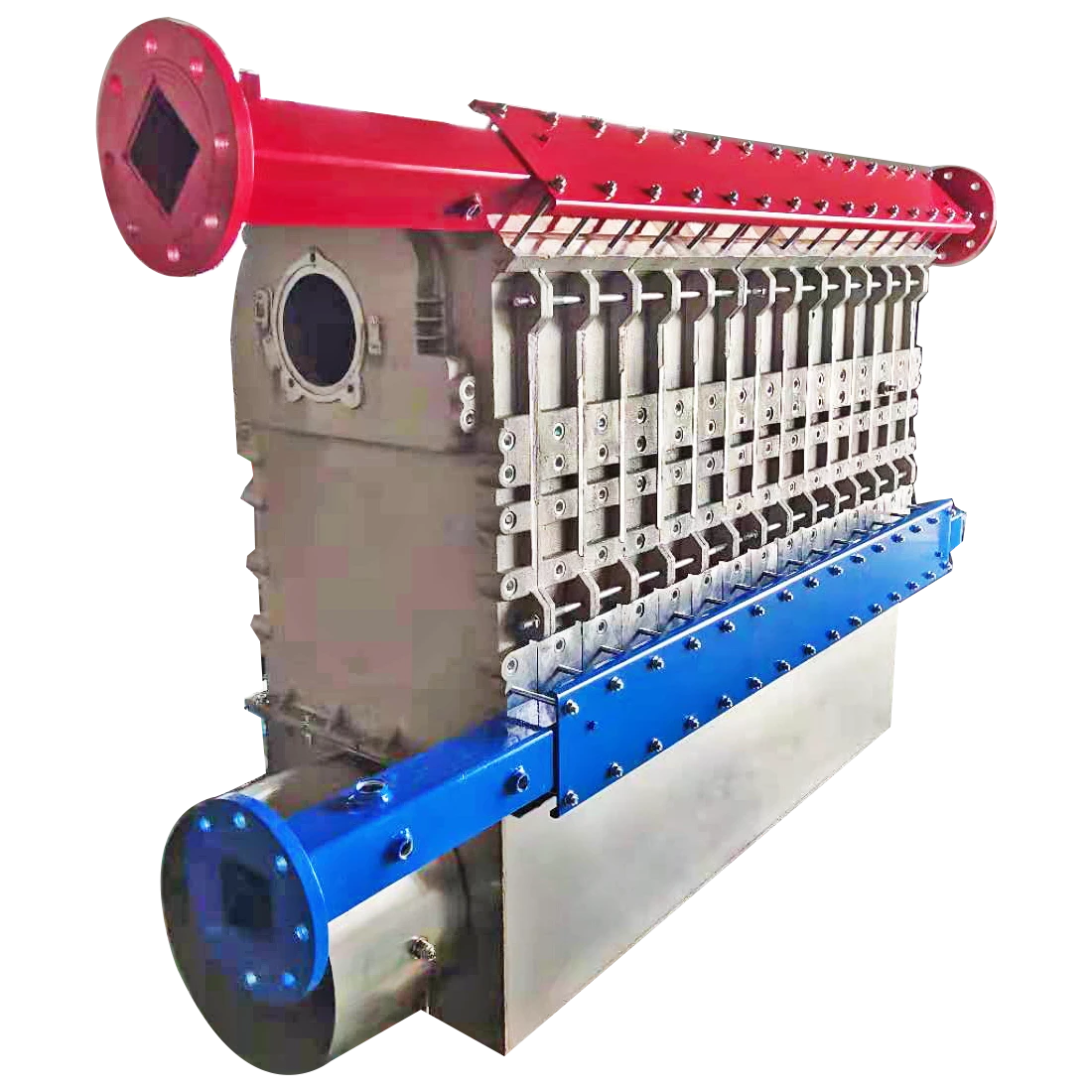

The Role of Ductile Iron Casting in Railway Accessories Manufacturing

Ductile iron casting has become a cornerstone of the railway accessories manufacturing industry, recognized for its exceptional strength, durability, and versatility. As the railway sector continues to evolve, the demand for robust components that can withstand harsh operating conditions is paramount. Ductile iron, also known as spheroidal graphite iron, exhibits superior mechanical properties compared to traditional gray iron, making it an ideal choice for various railway applications.

Advantages of Ductile Iron

One of the primary advantages of ductile iron is its outstanding tensile strength, which is essential for components subjected to high stress and dynamic loads. This material can endure significant impacts, making it suitable for railway fittings such as couplings, brackets, and rail fasteners. Additionally, ductile iron's excellent wear resistance contributes to a longer lifespan for railway accessories, reducing maintenance costs and downtime.

Moreover, ductile iron offers good machinability, allowing manufacturers to create complex geometries that meet specific design requirements. This adaptability means that components can be tailored for various railway systems, whether it be passenger transport or freight services. The capability to produce intricate designs without compromising the material's integrity is a significant advantage that has led to its widespread adoption.

Manufacturing Process

The production of ductile iron castings typically involves several steps, starting with the preparation of the molten iron. This process includes adding specific alloys, such as magnesium, to promote the formation of spheroidal graphite, which is crucial for achieving the desired mechanical properties. Once the molten iron has reached the right composition, it is poured into molds that are shaped to match the desired accessory.

After the casting solidifies, it undergoes various post-processing treatments, including machining, heat treatment, and surface finishing. These processes ensure that the final products not only meet stringent dimensional tolerances but also exhibit enhanced performance characteristics. Quality assurance through rigorous testing is essential to ensure that every piece meets safety standards and operational requirements.

Applications in the Railway Sector

railway accessory ductile iron casting manufacturers

Ductile iron castings are utilized in a myriad of railway applications

. Key components include1. Track Elements Ductile iron is used in rail anchors, tie plates, and other track components that require high strength and fatigue resistance.

2. Braking Systems Components like brake housings benefit from ductile iron's ability to handle thermal stress and provide durability under demanding conditions.

3. Signaling Equipment Signal bases and junction boxes made of ductile iron are resistant to environmental factors, ensuring long-term reliability.

4. Suspension Parts The resilience of ductile iron makes it an excellent choice for parts that must accommodate vibrations and shifting loads in various driving conditions.

Sustainability and Innovation

With the growing emphasis on sustainability in manufacturing, ductile iron casting aligns well with these objectives. The recycling of iron and steel products is widely practiced, allowing manufacturers to reduce raw material costs and environmental impact. Furthermore, advancements in technology have led to improved casting processes that enhance efficiency and reduce waste.

In conclusion, ductile iron casting plays a vital role in the production of railway accessories, providing strength, durability, and adaptability. As the railway industry continues to seek innovative solutions to meet modern challenges, ductile iron remains a material of choice. Its proven performance and sustainability credentials make it an essential component in the ongoing development of railway infrastructure worldwide, ensuring safe and efficient transport for years to come.

-

Premium Cast Iron Water Main Pipe for Robust Infrastructure

NewsAug.27,2025

-

A-Rated Cast Aluminum Boilers: High-Efficiency Condensing Gas & LPG

NewsAug.26,2025

-

OEM Cast Silicon Aluminum Alloy Heat Exchanger | Custom & High Performance

NewsAug.25,2025

-

Centrifugally Cast Iron Water Main Pipe | Ductile Iron Solutions

NewsAug.24,2025

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025