12-р сар . 20, 2024 00:35 Back to list

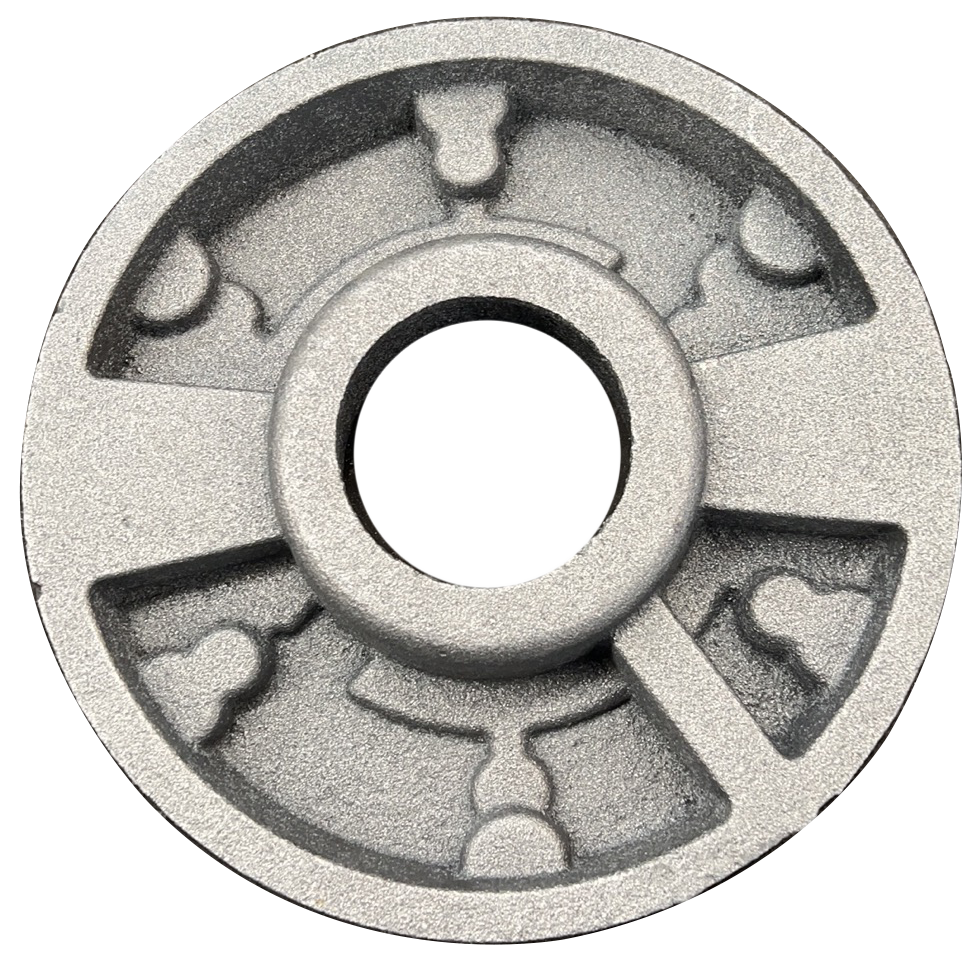

oem ductile iron pipe mould bottom ring

Understanding OEM Ductile Iron Pipe Mould Bottom Rings

The manufacturing of ductile iron pipes has become increasingly vital in various industries, particularly in water and wastewater management systems. Among the critical components in the fabrication process are the OEM (Original Equipment Manufacturer) ductile iron pipe mould bottom rings. These components play a significant role in ensuring the quality, durability, and overall performance of ductile iron pipes. In this article, we will explore the importance of these bottom rings, their design, manufacturing processes, and implications for the industry.

What Are Ductile Iron Pipe Mould Bottom Rings?

Ductile iron pipe mould bottom rings are essential parts of the manufacturing molds used in the production of ductile iron pipes. These rings help shape the pipe during the casting process and ensure that the final product meets the specified dimensions and quality standards. Generally made from high-quality materials like ductile iron itself, these rings can withstand the extreme conditions of the casting process, including high temperatures and molten metal.

Importance of OEM in Manufacturing

OEMs are critical in the production of industrial components, including ductile iron pipe mould bottom rings. By adhering to strict quality control standards, OEM manufacturers guarantee that every bottom ring produced meets rigorous specifications. This consistency is crucial because any irregularities in the bottom rings can lead to defects in the final pipe product, potentially affecting its strength and longevity.

Moreover, OEMs typically possess significant expertise in designing components that cater specifically to the needs of their clients. They are adept at utilizing advanced techniques and technologies in their manufacturing processes, ensuring that the rings provide precise dimensional accuracy and finish. The use of OEM components supports manufacturers in reducing waste and enhancing the efficiency of the production process.

Manufacturing Process

oem ductile iron pipe mould bottom ring

The production of ductile iron pipe mould bottom rings involves several steps. Initially, high-quality ductile iron is melted in furnaces at high temperatures. This molten metal is then cast into the desired shape of the bottom ring using precision molds. The cooling phase is crucial; it allows the molten iron to solidify and take on the necessary mechanical properties.

After cooling, the rings undergo various treatments to enhance their strength and durability. This may include heat treatment processes, surface finishing, and coating to resist corrosion. Quality inspections are conducted at various stages of manufacturing to ensure that each component meets the required specifications before being dispatched for use in pipe production.

Advantages of Using Ductile Iron

Ductile iron, as a material, offers several advantages over traditional cast iron and other materials. Its excellent tensile strength and ductility allow for the production of thinner walls, reducing material costs without compromising structural integrity. Ductile iron is also highly resistant to corrosion, making it an ideal choice for pipes that will be exposed to tough environmental conditions.

By utilizing OEM ductile iron pipe mould bottom rings, manufacturers can ensure that they are producing pipes that maintain these advantages effectively. The compatibility of these bottom rings with ductile iron materials enhances the overall performance of the pipes, extending their lifespan and reducing maintenance costs.

Conclusion

In summary, OEM ductile iron pipe mould bottom rings are crucial components in the efficient and effective production of ductile iron pipes. Their design, manufacturing processes, and material properties contribute significantly to the quality and performance of the final product. The reliance on OEM standards ensures that manufacturers can produce high-quality pipes that meet the demanding requirements of modern infrastructure projects. As industries continue to evolve, the role of these components is likely to become even more critical, reflecting the ongoing importance of quality in manufacturing. By investing in high-quality mould bottom rings, companies position themselves to thrive in an increasingly competitive market, ultimately leading to better infrastructure solutions worldwide.

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025