12-р сар . 04, 2024 16:47 Back to list

stainless steel casting factory

The Importance of Stainless Steel Casting Factories in Modern Manufacturing

In the realm of modern manufacturing, few materials have gained as much prominence as stainless steel. Renowned for its durability, corrosion resistance, and aesthetic appeal, stainless steel is a crucial component in numerous industries including automotive, aerospace, construction, and food processing. At the heart of producing high-quality stainless steel components lies the expertise of stainless steel casting factories. These factories play a vital role in not only creating various products but also in pushing the boundaries of technology and innovation.

Understanding Stainless Steel Casting

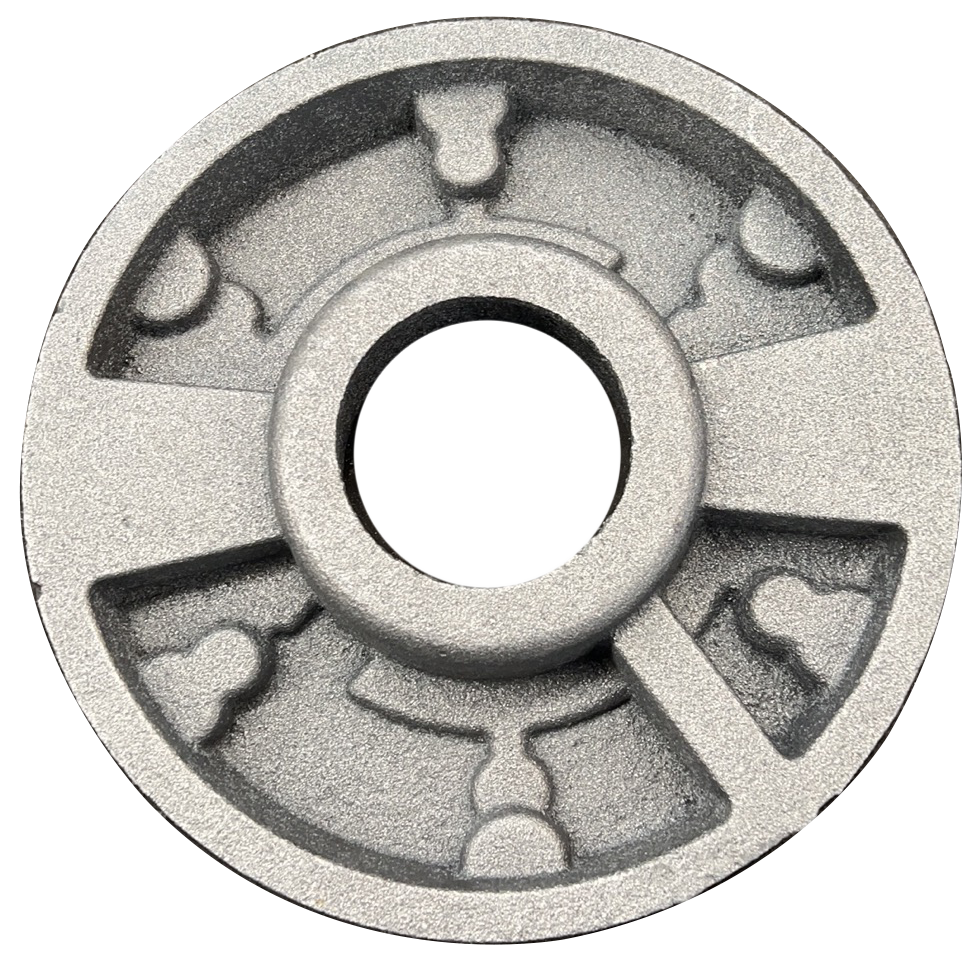

Stainless steel casting involves the process of pouring molten stainless steel into a mold to create intricate shapes and components. This method allows for the production of complex geometries that may be difficult or impossible to achieve through other manufacturing processes such as machining or forging. The casting process can produce components ranging from small, delicate parts to large industrial components, showcasing the versatility of stainless steel as a material.

There are several types of stainless steel casting methods, including gravity casting, investment casting, and sand casting. Each method has its advantages and is chosen based on the specific requirements of the component being produced. Investment casting, for instance, is known for its precision and ability to create high-quality surface finishes, making it ideal for complex parts that require tight tolerances.

Benefits of Using Stainless Steel

One of the primary reasons industries favor stainless steel is its resistance to corrosion and rust, which is especially crucial in environments exposed to moisture or harsh chemicals. This durability ensures that components maintain their integrity over time, reducing the need for frequent replacements and maintenance. Additionally, stainless steel is highly versatile, making it suitable for a wide range of applications.

Beyond functional benefits, stainless steel also offers aesthetic advantages. Its shiny finish and the ability to be polished to a high sheen make it a popular choice for both industrial and decorative applications. This aesthetic quality contributes to the growing trend of using stainless steel in architecture and design, where both form and function are essential.

stainless steel casting factory

The Role of Stainless Steel Casting Factories

Stainless steel casting factories are at the forefront of manufacturing processes that ensure the availability of high-quality, reliable components. These factories not only bring together skilled labor but also utilize advanced technology to enhance production efficiency and quality control. Automation and computer-aided design (CAD) have revolutionized the casting industry, enabling factories to produce intricate designs with greater accuracy.

Moreover, stainless steel casting factories are committed to sustainability and reducing their environmental footprint. Many factories now employ methods to recycle scrap metal and reduce waste, aligning with global efforts to promote sustainable manufacturing practices. This commitment to sustainability is becoming increasingly important as consumers and businesses alike prioritize environmentally-friendly processes.

Challenges and Innovations

Despite the advantages, stainless steel casting factories face several challenges. The fluctuating prices of raw materials, the need for continuous technological upgrades, and the competition from alternative manufacturing methods can pose significant hurdles. However, these challenges also drive innovation within the industry. Factories are investing in research and development to explore new alloys and casting techniques that can offer even greater benefits.

The integration of advanced technologies such as 3D printing and artificial intelligence into the casting process is paving the way for revolutionary changes. 3D printing can significantly reduce the time and cost associated with creating molds, while AI can optimize production schedules and predictive maintenance, ensuring seamless operations.

Conclusion

Stainless steel casting factories are essential players in the modern manufacturing landscape. Their ability to produce high-quality, durable components that meet the demands of various industries cannot be overstated. As the industry continues to evolve, these factories will remain at the forefront of innovation, committed to sustainability and efficiency. The future of stainless steel casting looks promising, with exciting advancements on the horizon that will further enhance its capabilities and applications. With continued investment in technology and skilled labor, stainless steel casting factories will play a pivotal role in shaping the future of manufacturing.

-

Centrifugally Cast Iron Water Main Pipe | Ductile Iron Solutions

NewsAug.24,2025

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025