डिसेंबर . 23, 2024 16:39 Back to list

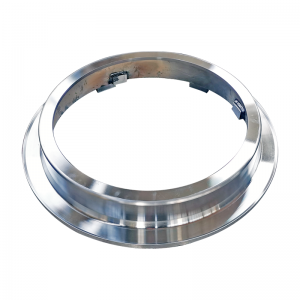

aluminum investment casting

The Growing Importance of Aluminum Investment Casting

Aluminum investment casting has emerged as a pivotal process in various industries, thanks to its unique advantages and the growing demand for lightweight, high-strength components. This innovative casting technique allows manufacturers to create intricate geometries and high-precision parts, making it ideal for sectors such as automotive, aerospace, medical, and electronics. As the industry continues to evolve, understanding the advantages, process, and applications of aluminum investment casting becomes increasingly essential.

What is Aluminum Investment Casting?

Aluminum investment casting, also known as lost-wax casting, is a process that involves creating a precise metal component from a wax pattern. The process typically includes several steps creating a wax model of the desired part, coating the model with a ceramic shell, heating the shell to remove the wax, and finally pouring molten aluminum into the shell to form the part. Once cooled and solidified, the ceramic shell is broken away to reveal the finished aluminum product.

This method is highly favored for its ability to produce complex shapes with excellent surface finishes, reducing the need for extensive machining. Moreover, aluminum's light weight and corrosion resistance make it a preferred material in modern manufacturing processes.

Advantages of Aluminum Investment Casting

1. Precision and Detail One of the most significant advantages of aluminum investment casting is its ability to produce parts with exceptional dimensional accuracy. The process allows for intricate designs that can be manufactured with tolerances as tight as ±0.005 inches.

2. Material Efficiency Investment casting significantly reduces waste compared to other manufacturing methods. The initial wax pattern may be reused multiple times, minimizing material costs and promoting sustainable practices.

3. Surface Finish Parts produced through investment casting often have a superior surface finish that may eliminate or reduce the need for secondary operations. This characteristic is especially beneficial for aesthetically sensitive applications and aerodynamic surfaces.

4. Versatility This casting method can accommodate various aluminum alloys, allowing manufacturers to select the best material to meet specific performance requirements. This versatility extends to automotive components like engine blocks and transmission housings, as well as aerospace parts and medical devices.

aluminum investment casting

5. Weight Reduction The lightweight nature of aluminum makes it an excellent choice for industries where reducing weight is crucial, such as aerospace and automotive. Lighter parts lead to increased fuel efficiency and improved overall performance.

Applications of Aluminum Investment Casting

The use of aluminum investment casting spans numerous industries, underlining its versatility and functionality.

- Aerospace High-performance aircraft components such as structural parts and turbine casings are frequently produced using aluminum investment casting. The ability to create complex geometries with lightweight materials is vital in this sector, where efficiency is paramount.

- Automotive The automotive industry benefits from aluminum investment casting to produce components including engine parts, wheels, and transmission cases. These components' lightweight properties contribute to overall vehicle efficiency, fuel economy, and performance.

- Medical Devices Precision medical devices require stringent quality standards. Aluminum investment casting is used for surgical instruments, implants, and other complex components where precision and strength are critical.

- Electronics As electronic devices become more complex, the demand for lightweight and intricately designed casings and parts rises. Investment casting allows for efficient production of high-quality aluminum components used in various electronic applications.

Conclusion

Aluminum investment casting stands as a cornerstone technology in contemporary manufacturing, offering numerous benefits that cater to various industries. As manufacturing processes continue to advance, the demand for precise, lightweight, and durable components will only increase. By investing in aluminum investment casting, companies can enhance their productivity, innovate their product offerings, and meet the ever-evolving challenges of a competitive market. The importance of this casting method cannot be overstated, as it plays a crucial role in shaping the future of manufacturing across the globe.

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025

-

Buy Cast Iron Pipe: Premium Ductile Iron & Drain Solutions

NewsAug.07,2025

-

Durable Cast Iron Water Main Pipe | Buy Ductile Pipe

NewsAug.06,2025