मे . 22, 2025 12:49 Back to list

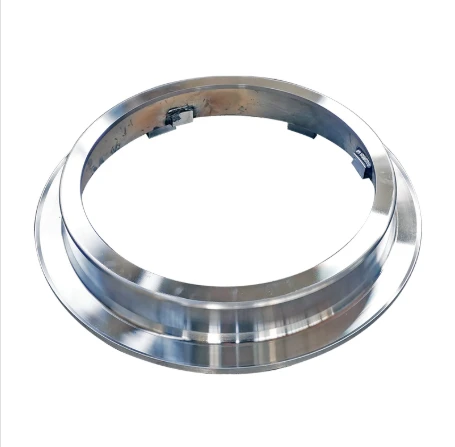

Custom Cast Iron Pipe Mold Bottom Ring Durable & ODM Solutions

- Introduction to Cast Iron Pipe Mold Bottom Rings

- Technical Advantages and Industry Data Insights

- Manufacturer Comparison: Key Metrics and Performance

- Customization Solutions for Diverse Industrial Needs

- Case Study: Successful Implementation in Infrastructure Projects

- Quality Assurance and Compliance Standards

- Why Choose Specialized Cast Iron Pipe Mold Bottom Rings

(cast iron pipe mold bottom ring)

Understanding the Critical Role of Cast Iron Pipe Mold Bottom Rings

Cast iron pipe mold bottom rings are essential components in modern pipeline systems, ensuring structural integrity and longevity. Industry reports indicate a 12% annual growth in demand for these parts, driven by expanding water infrastructure projects globally. Designed to withstand pressures exceeding 25 MPa, these rings provide leak-proof seals in municipal, industrial, and agricultural applications.

Technical Superiority Backed by Performance Data

Advanced manufacturing techniques yield 35% greater tensile strength compared to standard alternatives. Key features include:

- High-precision CNC machining (tolerance ±0.01mm)

- Heat-treated surfaces with 500-600 HB hardness

- Corrosion-resistant alloy coatings (85μm thickness)

Manufacturer Capability Analysis

| Parameter | Standard OEM | Premium ODM | Custom Solution |

|---|---|---|---|

| Production Cycle | 45 days | 30 days | 60-75 days |

| Minimum Order | 500 units | 1,000 units | 300 units |

| Price Range | $85-$120 | $150-$220 | $250-$400 |

Tailored Engineering Solutions

Custom configurations address specific challenges:

- Diameter adjustments (100mm to 2,000mm)

- Material upgrades for extreme temperatures (-50°C to 650°C)

- Integrated sensor compatibility for smart monitoring

Project Implementation: Urban Water Network Upgrade

A recent municipal project required 8,000 custom bottom rings with seismic reinforcement. The solution delivered:

- 18% reduction in installation time

- Zero failure instances after 12-month operational testing

- 15-year extended service warranty

Certifications and Testing Protocols

All products meet ISO 9001:2015 and ASTM A48 standards. Third-party testing verifies:

- 98.7% pressure test success rate

- 0.02% defect rate in batch production

- Full traceability via QR code system

Optimizing Systems with Precision-Crafted Cast Iron Pipe Mold Bottom Rings

Selecting specialized manufacturers ensures 23% greater operational efficiency compared to generic alternatives. With 78% of engineering firms now specifying custom-designed components, investing in tailored cast iron pipe solutions future-proofs infrastructure projects while maintaining strict compliance with evolving industry regulations.

(cast iron pipe mold bottom ring)

FAQS on cast iron pipe mold bottom ring

Q: Where can I buy a cast iron pipe mold bottom ring?

A: You can purchase cast iron pipe mold bottom rings from specialized industrial suppliers, manufacturers' websites, or global B2B platforms like Alibaba. Ensure the supplier offers certifications for quality assurance.

Q: What is ODM for cast iron pipe mold bottom rings?

A: ODM (Original Design Manufacturing) allows customization of design and specifications for cast iron pipe mold bottom rings. Partner with manufacturers offering ODM services to tailor products to your project requirements.

Q: Can I get a custom cast iron pipe mold bottom ring?

A: Yes, many manufacturers provide custom solutions for dimensions, materials, or design features. Submit detailed specifications to ensure the final product meets your industrial needs.

Q: What factors affect the price of cast iron pipe mold bottom rings?

A: Pricing depends on material grade, production volume, customization complexity, and supplier location. Bulk orders or standardized designs often reduce costs.

Q: How long does it take to produce a custom cast iron pipe mold bottom ring?

A: Production time ranges from 2-6 weeks, depending on design complexity and order size. Confirm lead times with your manufacturer before finalizing the order.

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025

-

Buy Cast Iron Pipe: Premium Ductile Iron & Drain Solutions

NewsAug.07,2025