डिसेंबर . 09, 2024 17:40 Back to list

OEM Solutions for Cement Casting Manufacturing and Customization

The Role of OEM in Cement Casting Enhancing Quality and Efficiency

In the world of manufacturing, the term OEM stands for Original Equipment Manufacturer. This concept is particularly significant in the construction and materials industry, where OEMs produce specialized machinery and components used in cement casting. Cement casting, a process pivotal to various construction applications, including infrastructure, buildings, and precast elements, benefits greatly from OEM innovations and advancements. In this article, we will explore how OEMs influence cement casting, enhancing both quality and efficiency.

Understanding Cement Casting

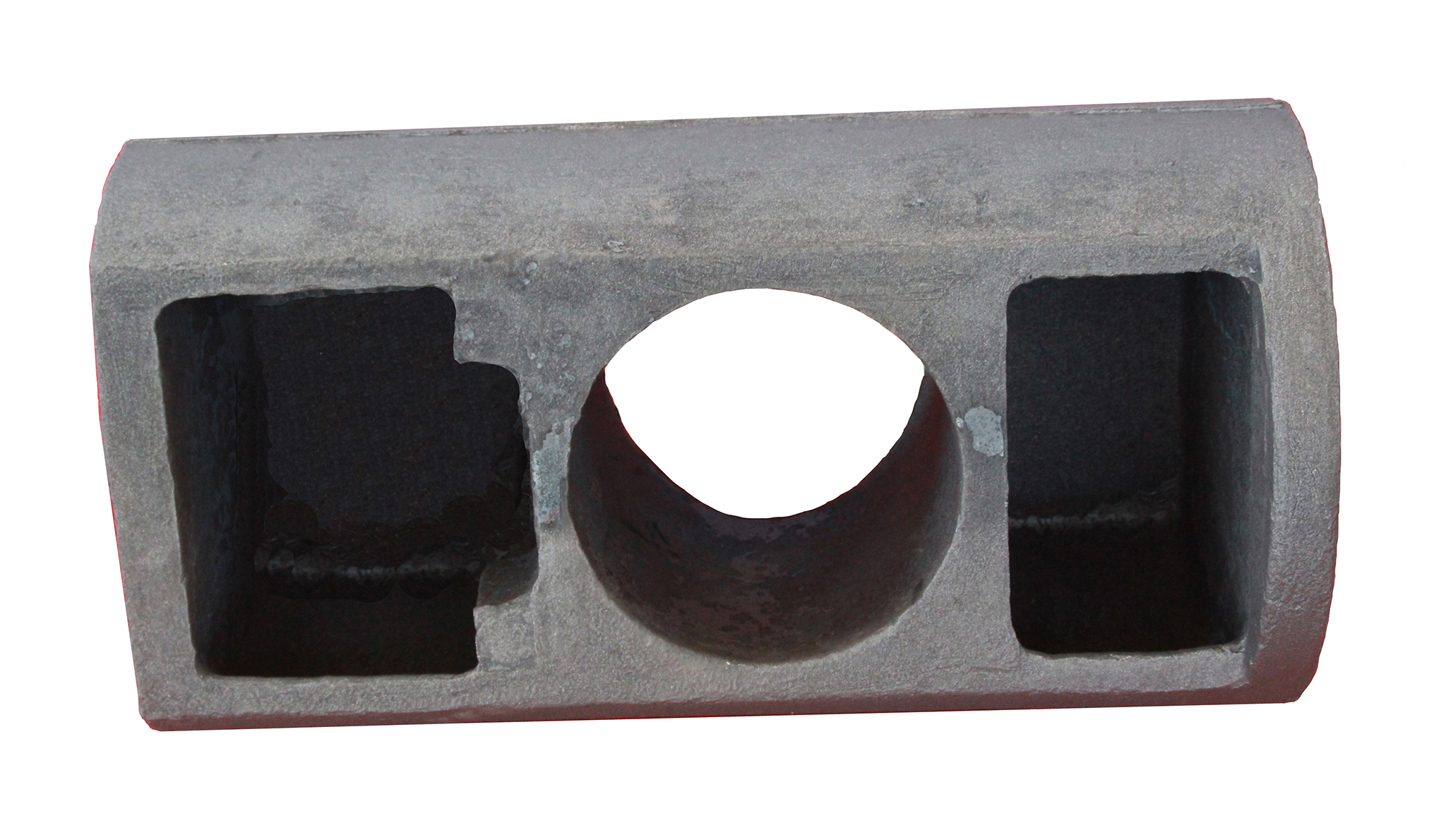

Cement casting involves pouring a cement mix into a mold to create various structures. This technique allows for the creation of complex shapes, ensuring that products meet specific design and structural requirements. Common applications of cement casting include pipes, blocks, slabs, and artistic sculptures. The quality of these end products largely depends on the materials used, the machinery involved in the casting process, and the expertise of the manufacturers.

The Influence of OEMs

OEMs play a crucial role in cement casting by providing high-quality equipment and components designed for optimal performance. Their specialization allows for the development of innovative solutions that address common challenges in the construction materials sector. Here are some key contributions of OEMs to cement casting

1. Advanced Machinery OEMs design and manufacture machinery specifically for cement mixing, pouring, and curing. This includes concrete mixers, molds, and casting machines that can perform at higher efficiency and precision. With advancements in technology, such as automation and robotics, these machines can significantly reduce production times and minimize human error.

2. Quality Control One of the critical aspects of cement casting is consistency in quality. OEMs utilize sophisticated technology to ensure that their machines maintain uniformity in the mixing and pouring processes. This consistency leads to stronger and more durable cement products, which is essential for safety and longevity in construction.

oem cement casting

3. Customization Another advantage of working with OEMs lies in their capacity for customization. Many construction projects have unique requirements, whether in terms of design, size, or material properties. OEMs can provide tailored solutions, ensuring that the molds and machines meet specific project needs. This flexibility is vital in a market that increasingly demands bespoke solutions.

4. Research and Development OEMs are often at the forefront of research and innovation. Continuous improvements in material science, engineering design, and process management allow them to introduce new technologies that enhance cement casting. This includes the development of environmentally friendly materials, such as recycled aggregates, and more efficient curing methods that reduce energy consumption.

5. Technical Support and Training Beyond machinery and materials, OEMs offer essential support services. They provide technical assistance during the installation and setup of equipment, as well as training for personnel to ensure safe and effective operation. This education is crucial for maintaining operational efficiency and safety standards in cement casting facilities.

The Future of Cement Casting with OEMs

As the construction industry evolves toward more sustainable practices, OEMs are likely to play an even more significant role in cement casting. The push for greener solutions, such as low-carbon cement and energy-efficient processes, presents both challenges and opportunities. OEMs have the potential to lead the way in developing new technologies that will not only satisfy regulatory demands but also address the growing concerns over carbon emissions associated with cement production.

Moreover, the integration of digital technologies such as 3D printing, IoT, and artificial intelligence into cement casting processes is on the horizon. These advancements will allow for even greater customization, efficiency, and quality control, further solidifying the importance of OEMs in the industry.

Conclusion

In conclusion, the role of OEMs in cement casting is indispensable. From providing advanced machinery and materials to offering customization and support, OEMs enhance both the quality and efficiency of the cement casting process. As the industry moves toward sustainability and innovation, OEMs will continue to be key players in shaping the future of construction materials, making cement casting not only more efficient but also more environmentally responsible.

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025

-

Buy Cast Iron Pipe: Premium Ductile Iron & Drain Solutions

NewsAug.07,2025