Dec . 05, 2024 20:44 Back to list

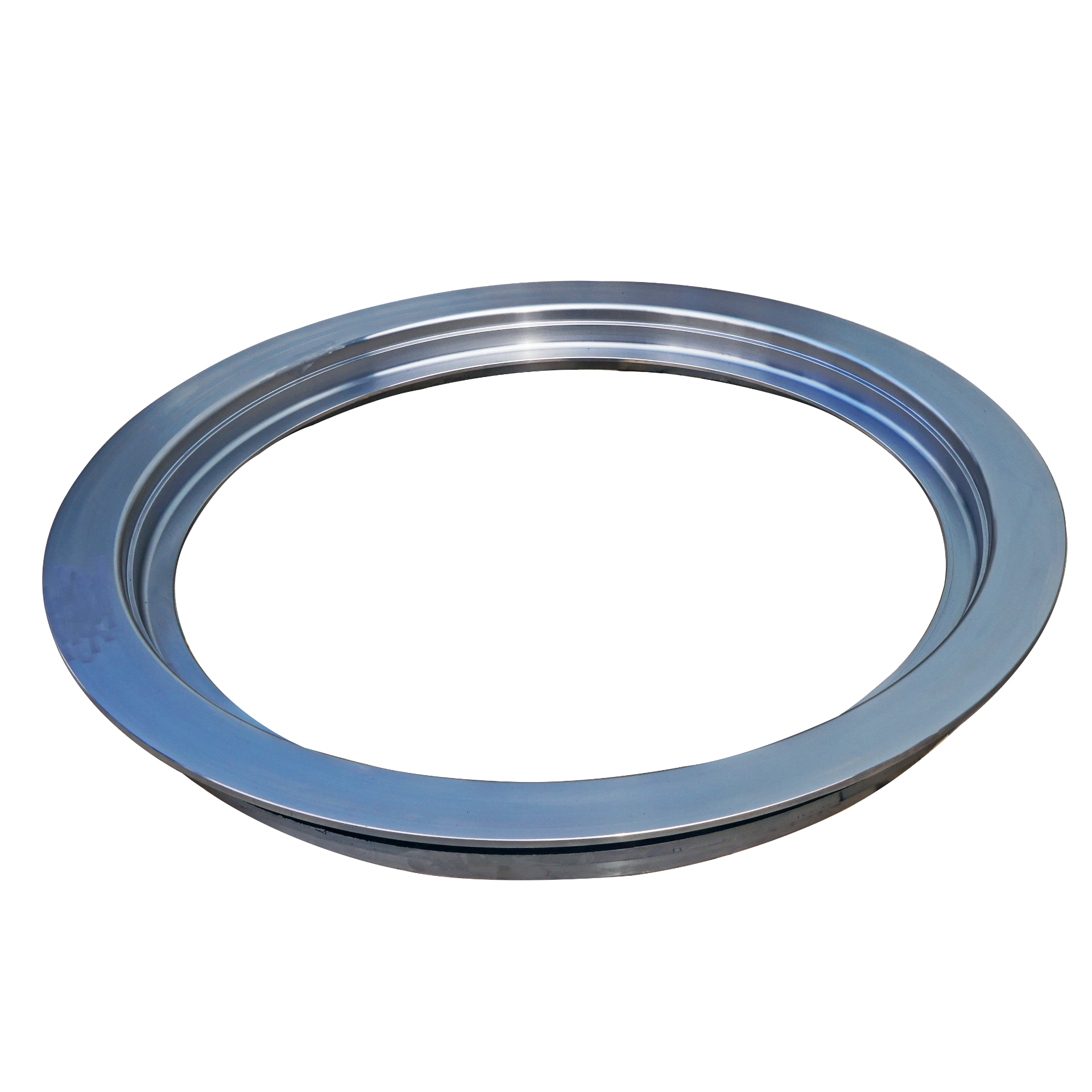

bronze investment casting manufacturer

The Significance of Bronze Investment Casting in Manufacturing

Bronze investment casting has gained recognition as an essential technique in the field of manufacturing. This method, which involves creating metal parts in a highly detailed and precise manner, has extensive applications across various industries including aerospace, automotive, marine, and artistic endeavors. This article explores the process, advantages, and applications of bronze investment casting, illustrating why it stands out as a valuable manufacturing technique.

Understanding Bronze Investment Casting

Bronze, an alloy primarily composed of copper and tin, is lauded for its strength, corrosion resistance, and excellent machinability. The investment casting process, also known as lost-wax casting, involves several crucial steps

1. Model Creation A precise model of the desired bronze part is made, often using wax or polymer. This model is an exact replica of the final product.

2. Mold Making After the model is created, it is coated with a ceramic shell that hardens. The wax is then melted away, leaving a cavity that shapes the final bronze casting.

3. Pouring Molten bronze is poured into the mold, filling the cavity and taking on the shape of the original model.

4. Cooling and Finishing Once the metal has cooled and solidified, the ceramic shell is broken away, revealing the finished part, which may undergo additional finishing processes for surface quality.

Advantages of Bronze Investment Casting

There are several reasons why bronze investment casting has become a preferred method of manufacturing for many industries

bronze investment casting manufacturer

- Precision and Complexity Investment casting allows for a high level of detail and complexity that other manufacturing techniques struggle to achieve. Fine features, undercuts, and intricate geometries can be produced with minimal machining, if any.

- Material Efficiency The process is known for producing minimal waste. The ability to create near-net-shape parts means that less material is wasted during production, making it an environmentally friendly option.

- Strength and Durability Bronze is renowned for its strength and toughness, making it suitable for components that must endure harsh conditions. Its resistance to corrosion also extends the lifespan of the parts manufactured.

- Versatility Bronze investment casting is adaptable to a wide range of applications. It can be employed to manufacture small, delicate components or large, robust parts, making it a versatile choice for different industries.

Applications of Bronze Investment Casting

The versatility of bronze investment casting is showcased through its applications. In the aerospace industry, for instance, precision-engineered components made using this technique are critical for aircraft performance and safety. Similarly, in the automotive sector, bronze parts can be found in engines and suspension systems, where durability and reliability are paramount.

Marine applications also benefit significantly from bronze investment casting. The alloy’s resistance to seawater corrosion makes it an ideal choice for components used in boats and submarines. Additionally, artists and sculptors often use this method to create detailed sculptures and art pieces, taking advantage of the method’s capacity for intricate design.

Conclusion

In conclusion, bronze investment casting serves as a cornerstone of modern manufacturing. Through its combination of precision, material efficiency, and versatility, it meets the demands of various industries while producing components that are both functional and aesthetically pleasing. As technology continues to advance, the role of bronze investment casting will likely expand, further enhancing its significance in the manufacturing landscape. Manufacturers looking to innovate and create high-quality, durable products should consider the advantages of bronze investment casting as a viable method for their production needs. Whether it’s in aerospace, automotive, marine, or artistic applications, bronze investment casting is poised to remain a key player in the world of manufacturing.

-

Centrifugally Cast Iron Water Main Pipe | Ductile Iron Solutions

NewsAug.24,2025

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025