Jun . 15, 2024 19:45 Back to list

Carbon steel casting suppliers nearby.

Choosing the Right Carbon Steel Casting Suppliers

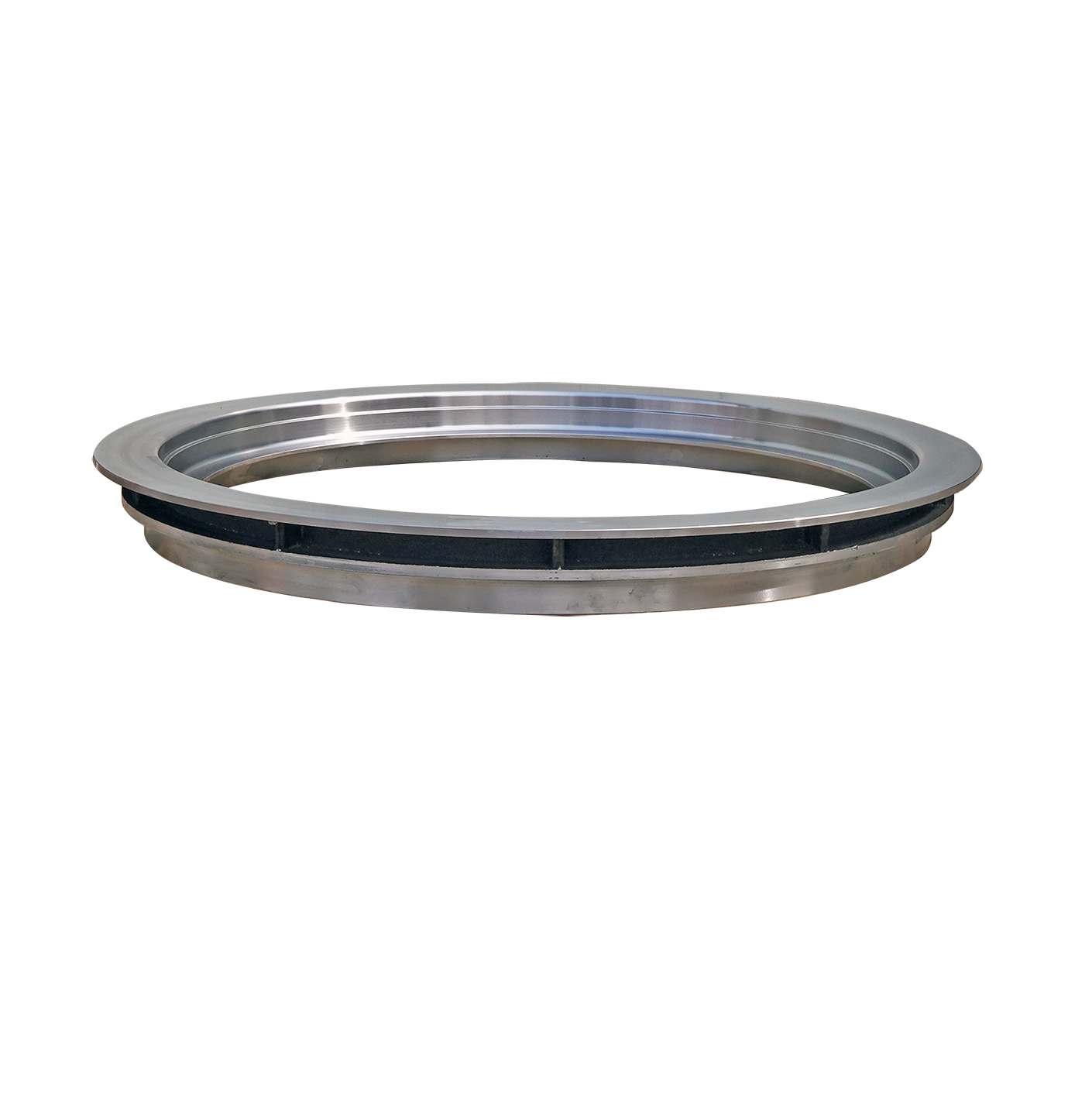

Carbon steel casting has been a cornerstone in various industries, from automotive to construction, due to its excellent strength, ductility, and cost-effectiveness. Selecting the right supplier is crucial for ensuring that your project specifications are met with quality and efficiency. In this brief guide, we will discuss key factors to consider when choosing carbon steel casting suppliers.

Firstly, it's essential to understand the different types of carbon steel available. Low-carbon steels have good formability and weldability but lower strength, whereas high-carbon steels offer higher strength and hardness but are more brittle and harder to weld. A reputable supplier should be able to provide options based on your specific needs.

Secondly, investigate the supplier’s experience and expertise in producing castings similar to your requirements. Look into their history, client testimonials, and case studies to gauge their capabilities. An experienced supplier will have a deep understanding of the casting process, including melting, pouring, and cooling techniques, which directly affect the final product's quality.

Thirdly, consider the scale of production and delivery timelines. Depending on your project size, you may require a supplier who can handle large volume orders without compromising quality. Timely delivery is also critical; projects can face costly delays if components are not supplied as per the agreed-upon schedule.

Quality assurance is another paramount aspect

Quality assurance is another paramount aspect Quality assurance is another paramount aspect

Quality assurance is another paramount aspect

Quality assurance is another paramount aspect

Quality assurance is another paramount aspect carbon steel casting suppliers. Ensure that potential suppliers have rigorous quality control measures in place, such as material testing, precision measurements, and defect inspection processes. Ask for certifications like ISO 9001, which demonstrates a commitment to meeting international standards for quality management systems.

Cost is always a significant factor, but remember that the lowest bidder may not always offer the best value. Consider the total cost of ownership, including potential rework or failure costs down the line. A supplier with competitive pricing and a track record of delivering high-quality castings could save you money in the long run.

Lastly, communication and customer service play important roles. A supplier that is responsive and transparent about their processes will make collaboration smoother. They should be able to provide clear information regarding lead times, order statuses, and any issues that arise during production.

In conclusion, selecting the right carbon steel casting suppliers involves careful consideration of their technical expertise, production capacity, quality assurance practices, cost-effectiveness, and customer service. By taking these factors into account, you can ensure that your project receives the precise, durable, and cost-efficient castings it deserves.

carbon steel casting suppliers. Ensure that potential suppliers have rigorous quality control measures in place, such as material testing, precision measurements, and defect inspection processes. Ask for certifications like ISO 9001, which demonstrates a commitment to meeting international standards for quality management systems.

Cost is always a significant factor, but remember that the lowest bidder may not always offer the best value. Consider the total cost of ownership, including potential rework or failure costs down the line. A supplier with competitive pricing and a track record of delivering high-quality castings could save you money in the long run.

Lastly, communication and customer service play important roles. A supplier that is responsive and transparent about their processes will make collaboration smoother. They should be able to provide clear information regarding lead times, order statuses, and any issues that arise during production.

In conclusion, selecting the right carbon steel casting suppliers involves careful consideration of their technical expertise, production capacity, quality assurance practices, cost-effectiveness, and customer service. By taking these factors into account, you can ensure that your project receives the precise, durable, and cost-efficient castings it deserves.

Quality assurance is another paramount aspect

Quality assurance is another paramount aspect

Quality assurance is another paramount aspect

Quality assurance is another paramount aspect carbon steel casting suppliers. Ensure that potential suppliers have rigorous quality control measures in place, such as material testing, precision measurements, and defect inspection processes. Ask for certifications like ISO 9001, which demonstrates a commitment to meeting international standards for quality management systems.

Cost is always a significant factor, but remember that the lowest bidder may not always offer the best value. Consider the total cost of ownership, including potential rework or failure costs down the line. A supplier with competitive pricing and a track record of delivering high-quality castings could save you money in the long run.

Lastly, communication and customer service play important roles. A supplier that is responsive and transparent about their processes will make collaboration smoother. They should be able to provide clear information regarding lead times, order statuses, and any issues that arise during production.

In conclusion, selecting the right carbon steel casting suppliers involves careful consideration of their technical expertise, production capacity, quality assurance practices, cost-effectiveness, and customer service. By taking these factors into account, you can ensure that your project receives the precise, durable, and cost-efficient castings it deserves.

carbon steel casting suppliers. Ensure that potential suppliers have rigorous quality control measures in place, such as material testing, precision measurements, and defect inspection processes. Ask for certifications like ISO 9001, which demonstrates a commitment to meeting international standards for quality management systems.

Cost is always a significant factor, but remember that the lowest bidder may not always offer the best value. Consider the total cost of ownership, including potential rework or failure costs down the line. A supplier with competitive pricing and a track record of delivering high-quality castings could save you money in the long run.

Lastly, communication and customer service play important roles. A supplier that is responsive and transparent about their processes will make collaboration smoother. They should be able to provide clear information regarding lead times, order statuses, and any issues that arise during production.

In conclusion, selecting the right carbon steel casting suppliers involves careful consideration of their technical expertise, production capacity, quality assurance practices, cost-effectiveness, and customer service. By taking these factors into account, you can ensure that your project receives the precise, durable, and cost-efficient castings it deserves. Share

Latest news

-

Centrifugally Cast Iron Water Main Pipe | Ductile Iron Solutions

NewsAug.24,2025

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025