Jun . 28, 2024 05:30 Back to list

Cast Silicon Aluminum Heat Exchangers for Commercial Heating Boilers - Leading Suppliers

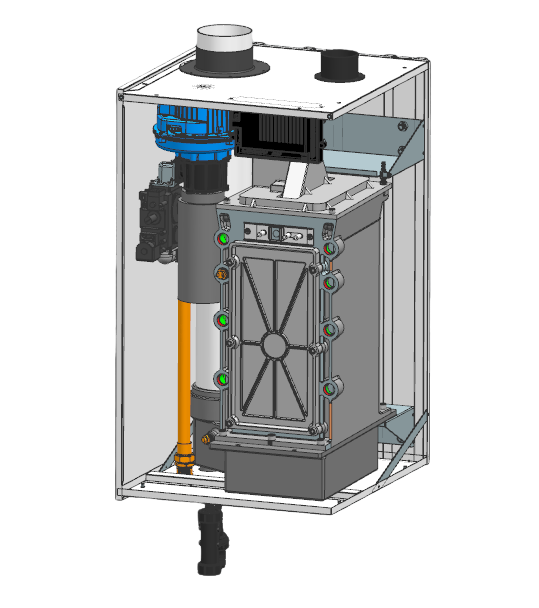

Enhancing Commercial Heating Boiler Efficiency with Cast Silicon Aluminum Heat Exchangers

In the realm of commercial heating solutions, boiler efficiency is a paramount concern. One innovative approach to bolstering this efficiency is through the integration of cast silicon aluminum heat exchangers. These specialized components offer a myriad of benefits that can significantly elevate the performance of commercial heating boilers. This article explores the advantages of utilizing cast silicon aluminum heat exchangers and highlights the importance of selecting reputable suppliers for these crucial components.

Cast silicon aluminum heat exchangers are renowned for their superior thermal conductivity. The unique alloy composition allows for rapid heat transfer, which is essential in commercial settings where large volumes of hot water or steam are required consistently. Compared to traditional materials like copper or steel, silicon aluminum alloys provide a more efficient pathway for heat, ensuring that boilers can operate at peak performance while minimizing energy waste.

Durability is another hallmark of cast silicon aluminum heat exchangers. The robust nature of the alloy resists corrosion and fatigue, extending the service life of the component. In the demanding environment of commercial boilers, where downtime can be costly, the longevity of the heat exchanger directly impacts operational reliability and reduces maintenance requirements In the demanding environment of commercial boilers, where downtime can be costly, the longevity of the heat exchanger directly impacts operational reliability and reduces maintenance requirements In the demanding environment of commercial boilers, where downtime can be costly, the longevity of the heat exchanger directly impacts operational reliability and reduces maintenance requirements In the demanding environment of commercial boilers, where downtime can be costly, the longevity of the heat exchanger directly impacts operational reliability and reduces maintenance requirements

In the demanding environment of commercial boilers, where downtime can be costly, the longevity of the heat exchanger directly impacts operational reliability and reduces maintenance requirements In the demanding environment of commercial boilers, where downtime can be costly, the longevity of the heat exchanger directly impacts operational reliability and reduces maintenance requirements cast silicon aluminum heat exchanger for commercial heating boiler suppliers.

Weight reduction is an additional perk of using cast silicon aluminum. Lighter heat exchangers not only ease the installation process but also lessen the structural burden on the boiler system as a whole. This aspect is particularly relevant for rooftop installations or situations where the boiler system must be supported above ground level.

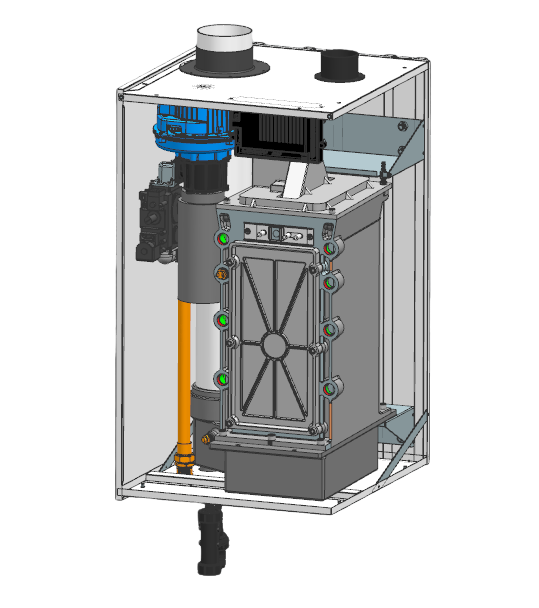

When sourcing cast silicon aluminum heat exchangers for commercial heating boilers, it is imperative to work with qualified suppliers. These suppliers must demonstrate expertise in engineering, manufacturing, and quality control to ensure that the heat exchangers meet the rigorous demands of commercial applications. Reputable suppliers will also offer comprehensive warranties and technical support, safeguarding the investment and providing peace of mind for facility managers.

The selection of cast silicon aluminum heat exchangers from trusted suppliers is a strategic decision that can markedly improve the efficiency, longevity, and overall performance of commercial heating boilers. As the market continues to emphasize sustainability and cost-effectiveness, embracing advanced technologies such as these specialized heat exchangers is becoming an increasingly essential step towards operational excellence.

cast silicon aluminum heat exchanger for commercial heating boiler suppliers.

Weight reduction is an additional perk of using cast silicon aluminum. Lighter heat exchangers not only ease the installation process but also lessen the structural burden on the boiler system as a whole. This aspect is particularly relevant for rooftop installations or situations where the boiler system must be supported above ground level.

When sourcing cast silicon aluminum heat exchangers for commercial heating boilers, it is imperative to work with qualified suppliers. These suppliers must demonstrate expertise in engineering, manufacturing, and quality control to ensure that the heat exchangers meet the rigorous demands of commercial applications. Reputable suppliers will also offer comprehensive warranties and technical support, safeguarding the investment and providing peace of mind for facility managers.

The selection of cast silicon aluminum heat exchangers from trusted suppliers is a strategic decision that can markedly improve the efficiency, longevity, and overall performance of commercial heating boilers. As the market continues to emphasize sustainability and cost-effectiveness, embracing advanced technologies such as these specialized heat exchangers is becoming an increasingly essential step towards operational excellence.

In the demanding environment of commercial boilers, where downtime can be costly, the longevity of the heat exchanger directly impacts operational reliability and reduces maintenance requirements In the demanding environment of commercial boilers, where downtime can be costly, the longevity of the heat exchanger directly impacts operational reliability and reduces maintenance requirements

In the demanding environment of commercial boilers, where downtime can be costly, the longevity of the heat exchanger directly impacts operational reliability and reduces maintenance requirements In the demanding environment of commercial boilers, where downtime can be costly, the longevity of the heat exchanger directly impacts operational reliability and reduces maintenance requirements cast silicon aluminum heat exchanger for commercial heating boiler suppliers.

Weight reduction is an additional perk of using cast silicon aluminum. Lighter heat exchangers not only ease the installation process but also lessen the structural burden on the boiler system as a whole. This aspect is particularly relevant for rooftop installations or situations where the boiler system must be supported above ground level.

When sourcing cast silicon aluminum heat exchangers for commercial heating boilers, it is imperative to work with qualified suppliers. These suppliers must demonstrate expertise in engineering, manufacturing, and quality control to ensure that the heat exchangers meet the rigorous demands of commercial applications. Reputable suppliers will also offer comprehensive warranties and technical support, safeguarding the investment and providing peace of mind for facility managers.

The selection of cast silicon aluminum heat exchangers from trusted suppliers is a strategic decision that can markedly improve the efficiency, longevity, and overall performance of commercial heating boilers. As the market continues to emphasize sustainability and cost-effectiveness, embracing advanced technologies such as these specialized heat exchangers is becoming an increasingly essential step towards operational excellence.

cast silicon aluminum heat exchanger for commercial heating boiler suppliers.

Weight reduction is an additional perk of using cast silicon aluminum. Lighter heat exchangers not only ease the installation process but also lessen the structural burden on the boiler system as a whole. This aspect is particularly relevant for rooftop installations or situations where the boiler system must be supported above ground level.

When sourcing cast silicon aluminum heat exchangers for commercial heating boilers, it is imperative to work with qualified suppliers. These suppliers must demonstrate expertise in engineering, manufacturing, and quality control to ensure that the heat exchangers meet the rigorous demands of commercial applications. Reputable suppliers will also offer comprehensive warranties and technical support, safeguarding the investment and providing peace of mind for facility managers.

The selection of cast silicon aluminum heat exchangers from trusted suppliers is a strategic decision that can markedly improve the efficiency, longevity, and overall performance of commercial heating boilers. As the market continues to emphasize sustainability and cost-effectiveness, embracing advanced technologies such as these specialized heat exchangers is becoming an increasingly essential step towards operational excellence. Share

Latest news

-

Centrifugally Cast Iron Water Main Pipe | Ductile Iron Solutions

NewsAug.24,2025

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025