Oct . 18, 2024 13:12 Back to list

Top Casting Product Manufacturers for Quality Industrial Solutions

The Role of Casting Product Manufacturers in Modern Industry

Casting is a fundamental manufacturing process that dates back thousands of years, rooted in the ability to shape molten metal into useful and intricate forms. Today, casting product manufacturers play a crucial role in a variety of sectors, including automotive, aerospace, construction, and consumer products. This article delves into the significance of casting in modern manufacturing, the various casting techniques, and the advancements shaping the industry.

Understanding Casting

Casting involves pouring molten material, typically metals or polymers, into a mold where it cools and solidifies into a specific shape. This method is highly valued for its ability to produce complex shapes that would be challenging or impossible to create through traditional machining methods. Types of casting processes include sand casting, investment casting, die casting, and permanent mold casting, each with distinct advantages and applications.

1. Sand Casting One of the oldest and most versatile casting techniques, sand casting uses sand as the mold material. It is particularly useful for large parts, and the process can accommodate various metals, including aluminum, iron, and steel. Sand casting is relatively low-cost and ideal for low to medium production runs.

2. Investment Casting Also known as lost-wax casting, this precise method is employed for creating intricate shapes with high levels of detail and smooth finishes. Common in the aerospace and automotive industries, investment casting allows for complex geometries and can significantly reduce the need for machining.

3. Die Casting This process involves forcing molten metal into a mold under high pressure, resulting in dense and dimensionally accurate parts. Die casting is predominantly used for high-volume production of smaller components, such as those found in consumer electronics and automotive parts.

4. Permanent Mold Casting This technique utilizes reusable molds, typically made from metal, to produce high-quality castings. The process offers better mechanical properties and dimensional accuracy compared to sand casting, making it a popular choice for medium-sized production runs.

Advantages of Casting

The benefits of casting are manifold. Firstly, it allows for the production of complex shapes that minimize the use of raw materials and reduce waste. The versatility in materials means manufacturers can choose the best metals suited for specific applications, enhancing performance and durability.

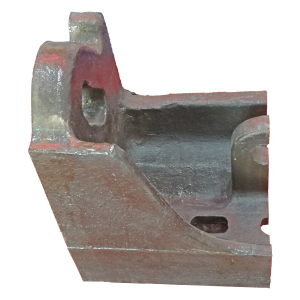

casting product manufacturer

Additionally, casting is cost-effective for mass production. The ability to create several castings from a single mold significantly lowers manufacturing costs in large-scale operations. Moreover, casting processes often require less finishing than other manufacturing methods, further streamlining production timelines.

Innovations in Casting Technology

As with many manufacturing processes, the casting industry is experiencing significant technological advancements. The introduction of computer-aided design (CAD) and computer-aided manufacturing (CAM) has revolutionized how designers and manufacturers approach casting. These technologies allow for improved simulation and optimization of molds before physical production begins, reducing material waste and enhancing product quality.

Additive manufacturing, commonly referred to as 3D printing, is also making its mark in casting. Manufacturers can now create complex casting molds using 3D printing technology, leading to faster prototyping and reduced lead times. This innovation enables manufacturers to respond quicker to market demands and customization requests.

Furthermore, advancements in materials science, such as the development of high-performance alloys and polymers, are expanding the range of casting applications. Manufacturers can now produce components that withstand extreme temperatures and corrosive environments, particularly in industries such as aerospace and petrochemical.

Environmental Considerations

In light of growing environmental concerns, casting product manufacturers are increasingly adopting sustainable practices. Efforts to reduce energy consumption during the melting and cooling processes, as well as recycling scrap metal, are becoming commonplace. Many manufacturers are also exploring green casting materials and processes that minimize environmental impact.

Conclusion

Casting product manufacturers occupy a pivotal position in the contemporary manufacturing landscape. Their ability to produce complex and durable components efficiently makes them indispensable across various industries. As technology continues to evolve, casting processes will likely become even more efficient and environmentally friendly, meeting the ever-growing demands of modern society. Through innovation, adaptation, and a commitment to sustainability, casting manufacturers are poised to thrive in the future, shaping the products that will drive tomorrow’s industries.

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025