Nov . 09, 2024 10:12 Back to list

Exploring Top Suppliers for Casting Services and Quality Materials

Understanding the Role of Casting Suppliers in Manufacturing

In the world of manufacturing, casting is an essential process that transforms raw materials into finished products. At the heart of this process are casting suppliers, companies that provide the necessary materials, tools, and expertise to ensure high-quality casting results. This article explores the role of casting suppliers, their significance in the industry, and the different types of suppliers that exist.

The Importance of Casting Suppliers

Casting suppliers play a crucial role in the manufacturing supply chain. They provide the essential materials, such as metals and alloys, that are used in the casting process. These materials must meet specific standards and specifications to ensure the quality and durability of the final product. Casting suppliers often work closely with manufacturers to understand their needs and provide customized materials that meet specific requirements.

Moreover, casting suppliers contribute to research and development. Many suppliers invest in innovation, improving their materials and processes to enhance the performance and efficiency of casting. By collaborating with manufacturers and other stakeholders in the production chain, casting suppliers help to drive technological advancements in the industry, leading to better products and more efficient manufacturing processes.

Types of Casting Suppliers

Casting suppliers can be categorized into several types, each serving a unique purpose within the industry

.1. Material Suppliers These suppliers provide the raw materials needed for casting, including metals like aluminum, steel, iron, and specialty alloys. They ensure that the materials meet industry standards and are suitable for the casting processes employed by manufacturers.

2. Coating and Additive Suppliers Coatings and additives play a crucial role in the casting process, enhancing the properties of the cast products and reducing defects. Suppliers of these materials provide essential products such as release agents, binders, and additives that help improve the quality of the casted items.

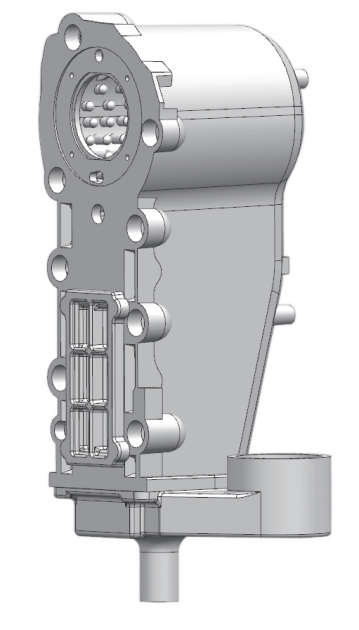

casting suppliers

3. Equipment Suppliers The casting process requires specialized equipment, including furnaces, molds, and other apparatus. Equipment suppliers provide the necessary tools and machinery needed for efficient casting operations. They often offer support services, including maintenance and training, to ensure that manufacturers can maximize the use of their equipment.

4. Consulting and Engineering Services Some suppliers extend their services beyond materials and equipment. They offer consulting and engineering expertise to help manufacturers optimize their casting processes. This can include process analysis, material selection, and design services to create efficient and effective casting solutions tailored to meet specific manufacturing needs.

The Future of Casting Suppliers

As industries continue to evolve, casting suppliers must adapt to emerging trends and challenges. One significant trend is the increasing focus on sustainability. Manufacturers are increasingly seeking eco-friendly materials and processes, prompting casting suppliers to explore alternative materials and reduce waste in their operations.

Additionally, advancements in technology, such as 3D printing and computer-aided design (CAD), are changing the landscape of casting. Casting suppliers must stay updated with these innovations to provide cutting-edge solutions that meet the evolving demands of their clients.

Furthermore, globalization has led to a more interconnected supply chain, requiring casting suppliers to manage international logistics and navigate regulatory requirements. This has increased the importance of reliability and communication among suppliers and manufacturers, fostering a collaborative approach to problem-solving and innovation.

Conclusion

Casting suppliers are vital players in the manufacturing process, providing essential materials, equipment, and expertise that drive the casting process. Their role extends beyond mere supply, as they contribute to R&D, sustainability efforts, and technological advancements. As the manufacturing landscape continues to evolve, casting suppliers will need to adapt to new challenges and opportunities to remain competitive and meet the needs of their clients. Ultimately, the success of the casting process is heavily reliant on the quality and reliability of the suppliers involved, underscoring their importance in the broader manufacturing ecosystem.

-

Centrifugally Cast Iron Water Main Pipe | Ductile Iron Solutions

NewsAug.24,2025

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025