Nov . 15, 2024 03:14 Back to list

cast iron pipe mould palet manufacturers

The Evolution and Significance of Cast Iron Pipe Mould Pallet Manufacturers

In the world of construction and plumbing, the materials used play a pivotal role in defining the quality and longevity of structures. One such critical material is the cast iron pipe, renowned for its durability and strength. Behind the scenes of producing these robust pipes is an equally important player the cast iron pipe mould pallet manufacturers. This article delves into their significance, production techniques, and future prospects in the industry.

The Role of Cast Iron Pipe Mould Pallets

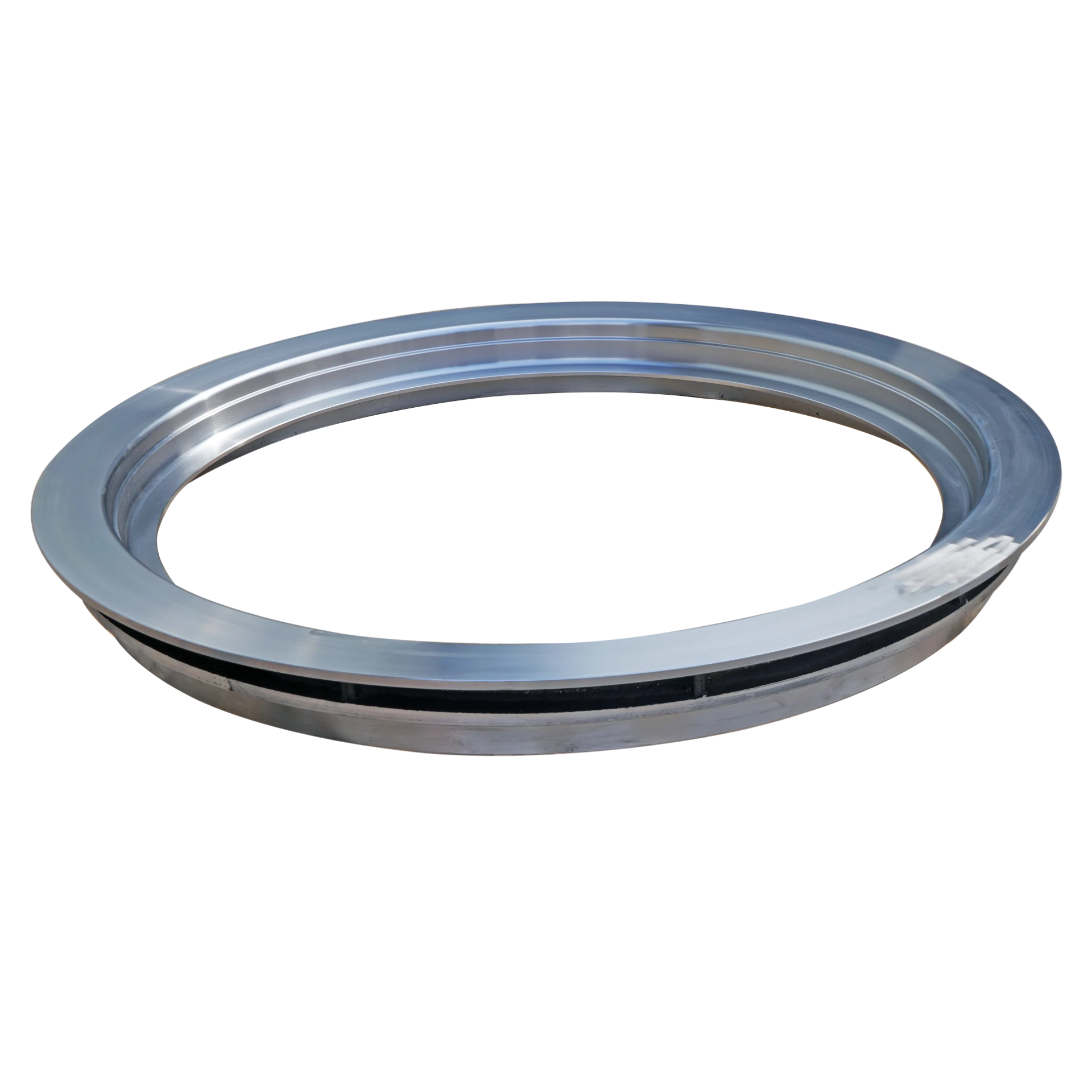

Mould pallets serve as the backbone of the casting process for pipes. They are essential for shaping the molten cast iron into the cylindrically perfect pipes we rely on today. The effectiveness of these pallets directly impacts the efficiency of production, the quality of the finished product, and ultimately, the overall cost of manufacturing.

Cast iron pipe mould pallets must withstand high temperatures and abrasive materials during the casting process. Therefore, manufacturers are tasked with creating pallets that are not only durable and resistant to deformation but also provide excellent insulation properties to optimize the casting operation.

Manufacturing Process

The production of cast iron pipe mould pallets involves several critical steps. Initially, high-quality materials are sourced, often involving specialized alloys that can endure the rigorous conditions encountered during the casting process. Advanced manufacturing techniques, including precision machining and computer-aided design (CAD), are employed to ensure the pallets meet exact specifications.

Quality control is paramount in the manufacturing process. Each pallet undergoes rigorous testing to ensure it adheres to industry standards. This includes assessments of durability, thermal resistance, and overall structural integrity. Manufacturers that invest in state-of-the-art technology and skilled craftsmanship can significantly enhance the operational efficiency of pipe production.

cast iron pipe mould palet manufacturers

Customization and Adaptability

One of the defining characteristics of the most successful cast iron pipe mould pallet manufacturers is their ability to offer customized solutions. Different projects may require unique design specifications based on factors such as pipe diameter, thickness, and application. By working closely with clients, manufacturers can create bespoke pallets tailored to specific operational needs, thereby improving the overall effectiveness of the casting process.

Moreover, in an industry that is increasingly pivoting towards sustainability, there is a growing demand for eco-friendly materials and practices. Manufacturers are responding to this trend by exploring alternative materials for pallet production and implementing greener manufacturing processes. Such adaptations not only reduce the environmental footprint but also meet the rising expectations of environmentally conscious consumers and industries.

The Future of Cast Iron Pipe Mould Pallet Manufacturing

As we look ahead, the landscape of the cast iron pipe mould pallet manufacturing industry is ripe for innovation. Advances in technology, such as automation and artificial intelligence, are set to revolutionize production workflows. These technologies promise to enhance efficiency, decrease production costs, and improve product quality.

Moreover, the ongoing globalization of the construction industry presents both challenges and opportunities. Manufacturers must stay competitive by focusing on innovation, quality, and customer service. Those that can swiftly adapt to changing market demands while maintaining high standards will thrive in this competitive landscape.

Conclusion

Cast iron pipe mould pallets may be an unsung component in the world of plumbing and construction, but their significance is undeniable. Manufacturers of these essential tools are at the forefront of innovation and quality, driving advancements that ultimately shape the structures we rely on every day. As the demand for durable and effective piping solutions continues to grow, the role of cast iron pipe mould pallet manufacturers will be critical in ensuring the industry meets the needs of both today and tomorrow. Emphasizing quality, customization, and sustainability will define the future of these manufacturers as they contribute to a resilient and efficient infrastructure.

-

Centrifugally Cast Iron Water Main Pipe | Ductile Iron Solutions

NewsAug.24,2025

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025