Oct . 07, 2024 09:24 Back to list

cast silicon aluminum alloy heat exchanger manufacturer

The Rise of Cast Silicon Aluminum Alloy Heat Exchangers A Comprehensive Overview

In today's rapidly evolving technological landscape, the demand for efficient and effective heat exchange systems has never been greater. Industries ranging from automotive to aerospace and energy production are constantly seeking innovative solutions to improve thermal management processes. One such solution gaining prominence is the use of cast silicon aluminum alloy heat exchangers. Manufacturers specializing in this technology are poised to transform the market, offering benefits that are hard to overlook.

Understanding Cast Silicon Aluminum Alloys

Cast silicon aluminum alloys are a group of aluminum-silicon alloys that are specifically designed for casting applications. These materials exhibit high thermal conductivity, excellent corrosion resistance, and good mechanical properties, making them ideal for heat exchanger applications. The addition of silicon enhances the fluidity of the alloy, allowing for easier casting into complex shapes, which is critical for optimizing heat transfer efficiency.

Why Choose Silicon Aluminum Alloy for Heat Exchangers?

One of the primary reasons heat exchanger manufacturers favor silicon aluminum alloys is their superior heat transfer capabilities. These alloys can efficiently transfer heat away from processing units, thereby improving energy efficiency and reducing operational costs. This attribute is particularly advantageous in applications where maintaining optimal temperature is crucial, such as in refrigeration systems, engine cooling, and HVAC units.

Another significant benefit of cast silicon aluminum alloys is their lightweight nature compared to traditional metal alloys, such as copper or stainless steel. This lightweight characteristic leads to reduced fabrication costs and simplified transportation. Moreover, the decrease in weight contributes to the overall efficiency of the systems in which they are installed, making them particularly appealing for transportable applications in the automotive and aerospace sectors.

Manufacturing Process and Innovation

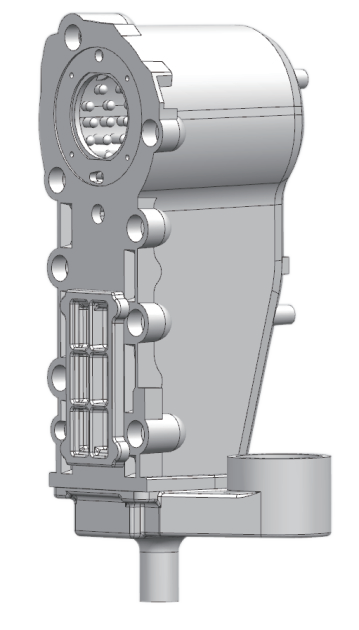

cast silicon aluminum alloy heat exchanger manufacturer

The manufacturing process of cast silicon aluminum alloy heat exchangers involves advanced casting techniques, including sand casting and die casting. These methods allow manufacturers to create intricate designs that enhance the performance of the heat exchanger. Innovations in mold technology and computer-aided design (CAD) further streamline the production process, enabling manufacturers to achieve higher precision and efficiency.

Leading manufacturers in this sector are also investing in research and development to explore new alloy compositions and hybrid materials that can further boost heat exchange performance and resistance to wear and tear. By collaborating with researchers and thermal engineers, these companies are pushing the boundaries of heat exchanger technology.

Sustainability and Eco-Friendliness

As industries face increasing pressure to adopt sustainable practices, silicon aluminum alloy heat exchangers present an environmentally friendly alternative. Aluminum is highly recyclable, and its use in heat exchangers contributes to reduced carbon footprints. Manufacturers are focusing on eco-friendly approaches, including using recyclable materials and implementing energy-efficient production methods.

Furthermore, by improving thermal efficiency, these heat exchangers help clients reduce energy consumption. This is particularly crucial in sectors like power generation and manufacturing, where energy costs can significantly impact overall profitability.

Future Prospects in the Market

The market for cast silicon aluminum alloy heat exchangers is expected to experience robust growth in the coming years. As industries strive for efficiency and sustainability, the demand for innovative heat management solutions will continue to rise. Manufacturers that prioritize quality, research, and sustainability will lead the charge.

In conclusion, cast silicon aluminum alloy heat exchangers represent a transformative solution in thermal management across multiple industries. With their superior performance, lightweight nature, and eco-friendly attributes, these heat exchangers are set to become a staple in modern manufacturing. As more industries recognize the advantages they offer, the role of specialized manufacturers in this sector will be pivotal in shaping a more energy-efficient and sustainable future.

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025