Nov . 16, 2024 00:28 Back to list

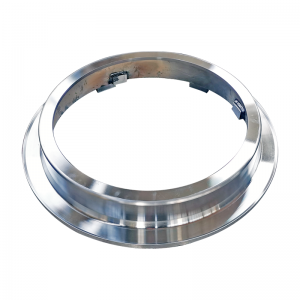

cast silicon aluminum heat exchanger for commercial heating boiler factory

Cast Silicon Aluminum Heat Exchangers for Commercial Heating Boilers

In the realm of industrial heating, efficiency and durability are paramount. One of the most innovative advancements in heating technology is the development of cast silicon aluminum heat exchangers. These components are increasingly being utilized in commercial heating boilers, offering a blend of superior performance and increased longevity.

Understanding Heat Exchangers

Heat exchangers play a crucial role in various applications, particularly in heating systems. Their primary function is to transfer heat between two or more fluids without mixing them. In commercial heating boilers, efficient heat transfer is essential for maintaining optimal performance and reducing energy consumption. Traditionally, heat exchangers were made from materials like copper or stainless steel, but the introduction of cast silicon aluminum has revolutionized the industry.

Why Cast Silicon Aluminum?

The choice of material is fundamental in the design of heat exchangers. Cast silicon aluminum combines the favorable properties of both aluminum and silicon, leading to several benefits

1. Thermal Conductivity Aluminum is known for its excellent thermal conductivity, allowing for efficient heat transfer. When alloyed with silicon, the thermal conductivity improves further, ensuring that heat is quickly and effectively transferred from the combustion gases to the water in the boiler.

2. Corrosion Resistance One of the most significant advantages of using cast silicon aluminum is its corrosion resistance. Compared to traditional materials, this alloy is less susceptible to oxidation and chemical degradation. This property is particularly advantageous in heating systems, where exposure to water and other fluids can lead to corrosion over time.

3. Lightweight Design Cast silicon aluminum is much lighter than stainless steel and other traditional materials. This characteristic can lead to lower shipping costs, easier handling during installation, and reduced structural load requirements for the heating system.

cast silicon aluminum heat exchanger for commercial heating boiler factory

4. Castabilty The casting process allows for complex shapes to be manufactured efficiently. This flexibility enables designers to create heat exchangers with intricate geometries that maximize surface area for heat transfer while minimizing material use.

5. Durability and Long Service Life Components made from cast silicon aluminum exhibit remarkable durability. The alloy can withstand high temperatures and pressures, making it suitable for demanding applications in commercial heating systems. As a result, the lifespan of heating boilers can be significantly extended, reducing the need for frequent replacements.

Application in Commercial Heating Boilers

The application of cast silicon aluminum heat exchangers in commercial heating boilers has made significant strides in recent years. These heat exchangers can be found in various settings, including

- Industrial Facilities Large manufacturing plants and warehouses often require substantial heating capacities. The efficiency and durability of cast silicon aluminum heat exchangers make them ideal for these high-demand environments.

- District Heating Systems In urban areas, district heating systems that supply hot water to multiple buildings benefit from the efficiency of these heat exchangers, which can effectively serve large networks.

- Hospitality Settings Hotels and restaurants rely heavily on consistent heating for guest comfort and food safety. The use of reliable heat exchangers ensures that these businesses can provide the necessary heating without interruptions.

Conclusion

The emergence of cast silicon aluminum heat exchangers marks a significant advancement in the field of commercial heating. Their exceptional thermal conductivity, corrosion resistance, lightweight nature, and durability make them an ideal choice for modern heating boilers. As industries strive for greater efficiency and sustainability, the adoption of these innovative materials will undoubtedly play a pivotal role in shaping the future of heating technology. With an ever-increasing emphasis on energy efficiency and longevity, cast silicon aluminum heat exchangers stand out as a dependable solution in a rapidly evolving market.

-

Centrifugally Cast Iron Water Main Pipe | Ductile Iron Solutions

NewsAug.24,2025

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025