Jun . 25, 2024 07:01 Back to list

Concrete Pipe Mould Stamps, Cement Pallets & Molds Suppliers

Exploring the Realm of Stamp Cement Pipe Mold Pallet Suppliers A Comprehensive Overview

In the intricate world of construction and infrastructure development, the production of high-quality cement pipes is a vital aspect that cannot be overlooked. These pipes, extensively used for sewage systems, stormwater management, and various other applications, demand precision engineering and robust manufacturing processes. Central to this process are stamp cement pipe mold pallet suppliers, who play a pivotal role in ensuring efficiency, uniformity, and durability of the end products. This article delves into the realm of these suppliers, highlighting their significance, the technology they employ, and the factors to consider when selecting a reliable partner.

**The Significance of Stamp Cement Pipe Mold Pallets**

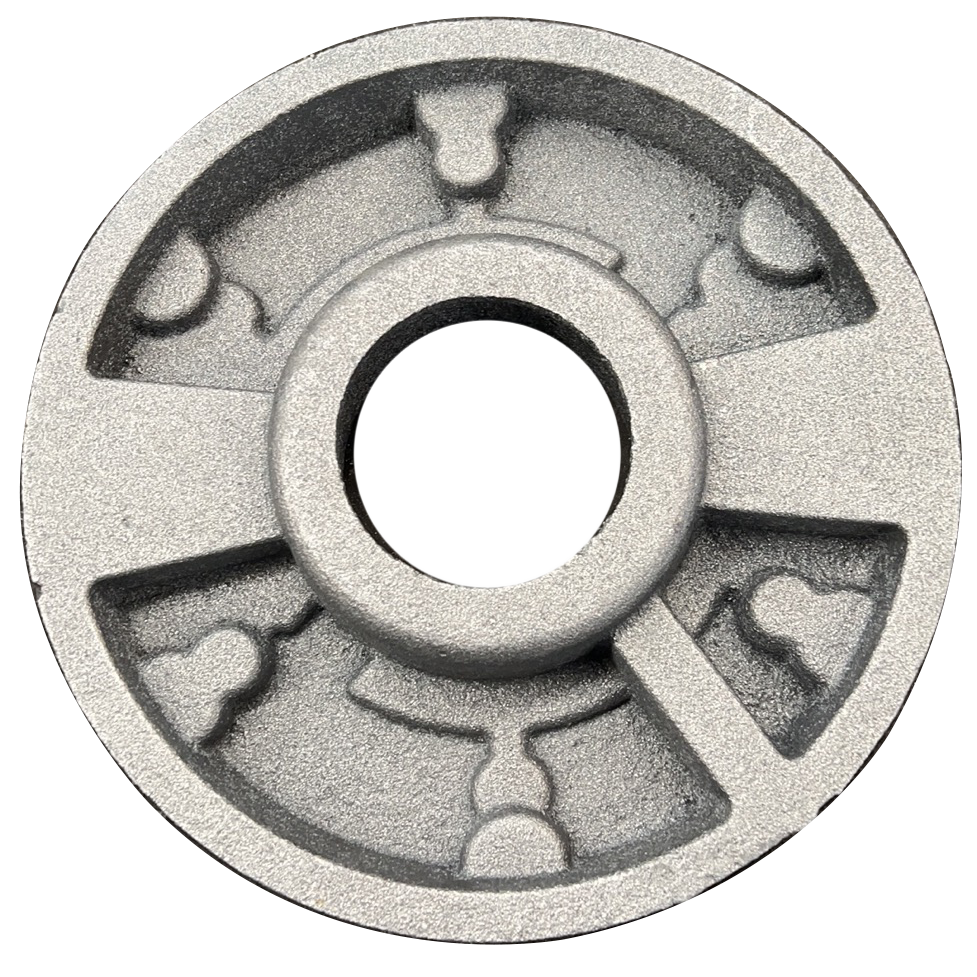

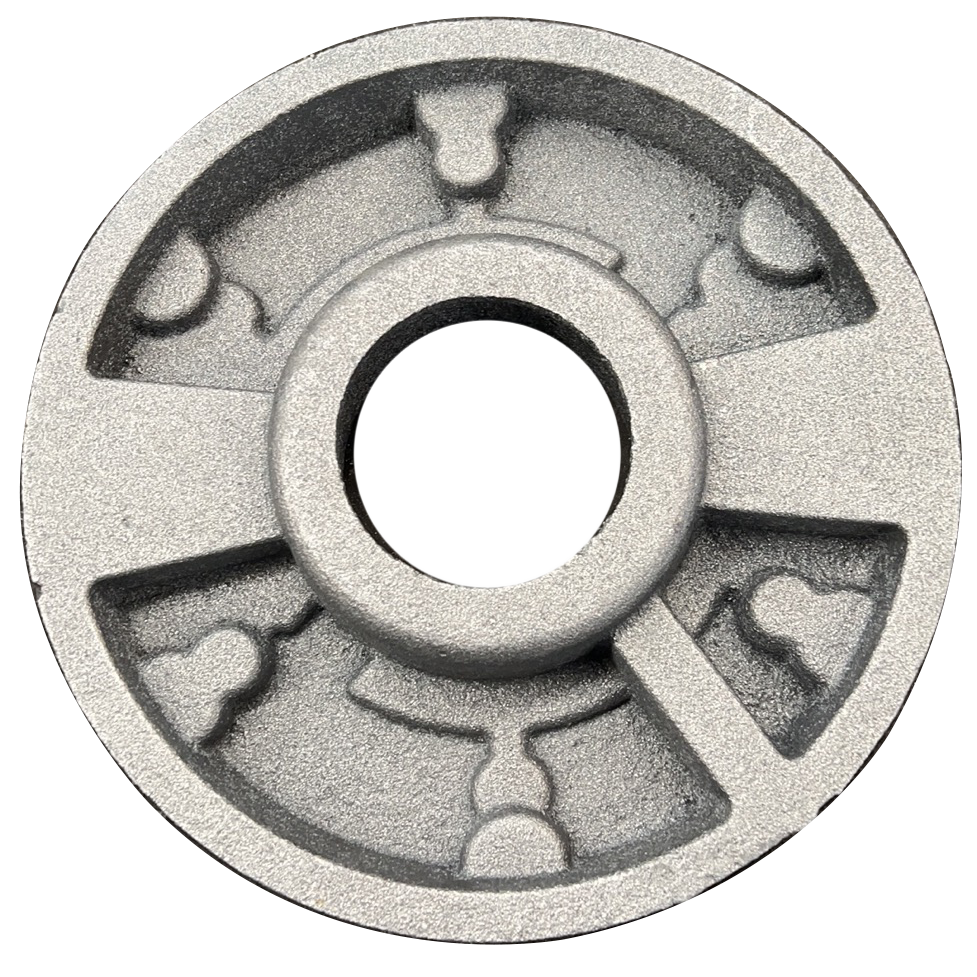

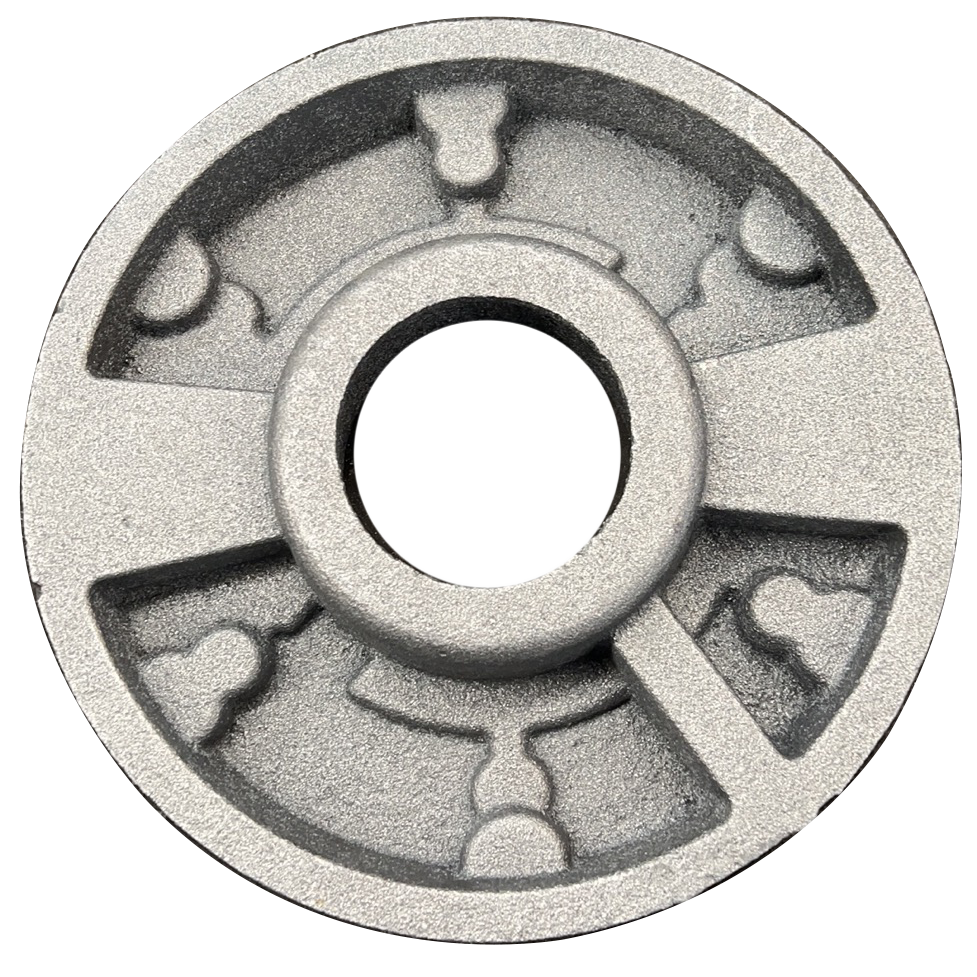

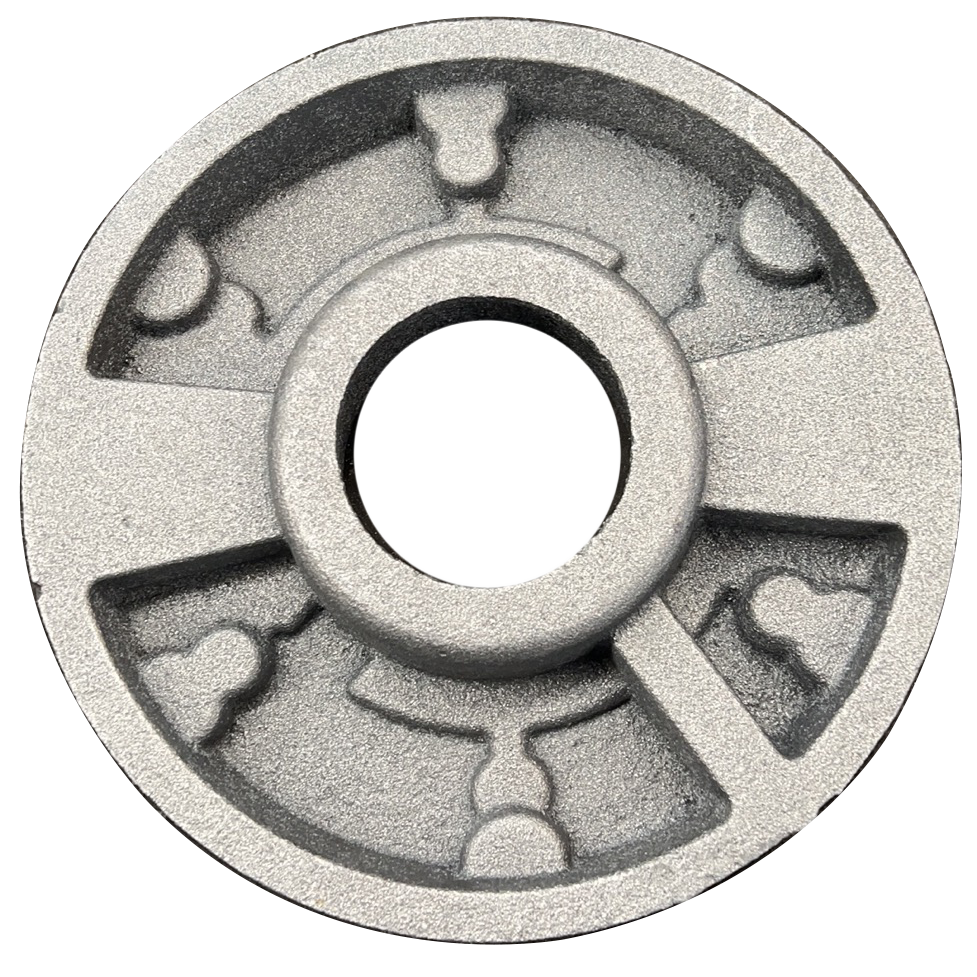

Stamp cement pipe manufacturing relies heavily on molds that define the pipe's shape, size, and strength. These molds are typically made from steel or other durable materials and are mounted onto pallets. The pallet system not only facilitates the handling and transportation of the molds within the production facility but also ensures consistent quality by maintaining the mold's alignment during the casting process. The stamps used in conjunction with these molds imprint necessary details or logos onto the pipe surface, adding an element of traceability and branding.

**Technology and Innovation at Play**

Contemporary stamp cement pipe mold pallet suppliers have embraced technological advancements to enhance productivity and precision. Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) systems are frequently employed to design molds with intricate details and precise dimensions. Moreover, the use of automated and robotic systems for the application of stamps and the handling of molds has significantly reduced human error and increased throughput.

Innovative materials and coatings for the pallets ensure minimal adherence of concrete, facilitating easy release and prolonging the life of both the molds and pallets. Some suppliers even offer customized solutions tailored to specific project requirements, including varying pipe diameters, lengths, and wall thicknesses.

**Selecting the Right Supplier Key Factors to Consider**

With a myriad of stamp cement pipe mold pallet suppliers in the market, identifying a reliable partner can be daunting. Here are several key factors to consider

1. **Quality and Durability** Look for suppliers with a proven track record of delivering molds and pallets that withstand the rigors of continuous use without compromising on the quality of the finished pipes.

2

2 2

2

2

2 stamp cement pipe mold pallet suppliers. **Customization Capabilities** The ability to provide tailored solutions based on unique project specifications is invaluable. Suppliers who can customize mold designs and pallet sizes to meet specific needs often offer a competitive edge.

3. **Technology Integration** Suppliers embracing modern technologies such as automation, CAD/CAM, and advanced material science are likely to offer more efficient and accurate products.

4. **After-Sales Support** Prompt service and readily available replacement parts can significantly minimize downtime. Choose a supplier with a robust after-sales support system.

5. **Environmental Sustainability** With growing emphasis on eco-friendly practices, suppliers adopting sustainable manufacturing processes and materials are increasingly preferred.

6. **Cost-Effectiveness** While quality should never be compromised, cost-effectiveness is crucial. Compare quotes from different suppliers, factoring in long-term operational costs and potential savings through increased efficiency.

**Conclusion**

The role of stamp cement pipe mold pallet suppliers extends beyond mere provision of equipment; they are integral to ensuring the integrity and longevity of critical infrastructure projects. By embracing innovation, offering customization, and adhering to stringent quality standards, these suppliers contribute significantly to the overall efficiency and success of the construction industry. As infrastructure demands continue to escalate globally, the selection of the right supplier becomes a strategic decision that can impact project outcomes and ultimately, the sustainability of our built environment.

stamp cement pipe mold pallet suppliers. **Customization Capabilities** The ability to provide tailored solutions based on unique project specifications is invaluable. Suppliers who can customize mold designs and pallet sizes to meet specific needs often offer a competitive edge.

3. **Technology Integration** Suppliers embracing modern technologies such as automation, CAD/CAM, and advanced material science are likely to offer more efficient and accurate products.

4. **After-Sales Support** Prompt service and readily available replacement parts can significantly minimize downtime. Choose a supplier with a robust after-sales support system.

5. **Environmental Sustainability** With growing emphasis on eco-friendly practices, suppliers adopting sustainable manufacturing processes and materials are increasingly preferred.

6. **Cost-Effectiveness** While quality should never be compromised, cost-effectiveness is crucial. Compare quotes from different suppliers, factoring in long-term operational costs and potential savings through increased efficiency.

**Conclusion**

The role of stamp cement pipe mold pallet suppliers extends beyond mere provision of equipment; they are integral to ensuring the integrity and longevity of critical infrastructure projects. By embracing innovation, offering customization, and adhering to stringent quality standards, these suppliers contribute significantly to the overall efficiency and success of the construction industry. As infrastructure demands continue to escalate globally, the selection of the right supplier becomes a strategic decision that can impact project outcomes and ultimately, the sustainability of our built environment.

2

2

2

2 stamp cement pipe mold pallet suppliers. **Customization Capabilities** The ability to provide tailored solutions based on unique project specifications is invaluable. Suppliers who can customize mold designs and pallet sizes to meet specific needs often offer a competitive edge.

3. **Technology Integration** Suppliers embracing modern technologies such as automation, CAD/CAM, and advanced material science are likely to offer more efficient and accurate products.

4. **After-Sales Support** Prompt service and readily available replacement parts can significantly minimize downtime. Choose a supplier with a robust after-sales support system.

5. **Environmental Sustainability** With growing emphasis on eco-friendly practices, suppliers adopting sustainable manufacturing processes and materials are increasingly preferred.

6. **Cost-Effectiveness** While quality should never be compromised, cost-effectiveness is crucial. Compare quotes from different suppliers, factoring in long-term operational costs and potential savings through increased efficiency.

**Conclusion**

The role of stamp cement pipe mold pallet suppliers extends beyond mere provision of equipment; they are integral to ensuring the integrity and longevity of critical infrastructure projects. By embracing innovation, offering customization, and adhering to stringent quality standards, these suppliers contribute significantly to the overall efficiency and success of the construction industry. As infrastructure demands continue to escalate globally, the selection of the right supplier becomes a strategic decision that can impact project outcomes and ultimately, the sustainability of our built environment.

stamp cement pipe mold pallet suppliers. **Customization Capabilities** The ability to provide tailored solutions based on unique project specifications is invaluable. Suppliers who can customize mold designs and pallet sizes to meet specific needs often offer a competitive edge.

3. **Technology Integration** Suppliers embracing modern technologies such as automation, CAD/CAM, and advanced material science are likely to offer more efficient and accurate products.

4. **After-Sales Support** Prompt service and readily available replacement parts can significantly minimize downtime. Choose a supplier with a robust after-sales support system.

5. **Environmental Sustainability** With growing emphasis on eco-friendly practices, suppliers adopting sustainable manufacturing processes and materials are increasingly preferred.

6. **Cost-Effectiveness** While quality should never be compromised, cost-effectiveness is crucial. Compare quotes from different suppliers, factoring in long-term operational costs and potential savings through increased efficiency.

**Conclusion**

The role of stamp cement pipe mold pallet suppliers extends beyond mere provision of equipment; they are integral to ensuring the integrity and longevity of critical infrastructure projects. By embracing innovation, offering customization, and adhering to stringent quality standards, these suppliers contribute significantly to the overall efficiency and success of the construction industry. As infrastructure demands continue to escalate globally, the selection of the right supplier becomes a strategic decision that can impact project outcomes and ultimately, the sustainability of our built environment. Share

Pervious:

Latest news

-

Centrifugally Cast Iron Water Main Pipe | Ductile Iron Solutions

NewsAug.24,2025

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025